How Modern Manufacturing Achieves Smart Automation with Semi-Automatic Wrapper Machines

Semi Automatic Wrapper Machines for Smart Manufacturing Automation

What Is a Semi Automatic Wrapper Machine?

A Semi Automatic Wrapper Machine is an industrial packaging system designed to secure products or palletized loads using stretch film or wrapping material, where the machine performs the wrapping cycle automatically, but loading, positioning, or cycle initiation involves the operator.

Manufacturers widely adopt these machines because they offer an ideal balance between manual labor and full automation, making them suitable for growing factories, mixed production lines, and operations transitioning toward smart manufacturing.

Why Semi Automatic Wrapper Machines Matter in Modern Manufacturing

Modern factories demand efficiency, consistency, and flexibility without excessive capital investment. Semi automatic wrapper machines address these needs by:

Reducing labor fatigue and dependency

Ensuring consistent wrapping quality

Improving load stability during transport

Lowering film consumption and material waste

For many manufacturers, these machines act as a bridge between manual wrapping and fully automatic systems, especially in facilities with variable SKUs or limited floor space.

Step-by-Step: How a Semi Automatic Wrapper Machine Works

From a technical and operational standpoint, the process follows a precise and repeatable cycle:

Load Placement

The operator places the carton, bundle, or pallet onto the turntable or wrapping platform.Film Attachment

The operator manually attaches the stretch film to the product or pallet base.Cycle Initiation

The operator starts the wrapping cycle via a control panel or foot switch.Automatic Wrapping Process

The turntable rotates at a controlled speed

The film carriage moves vertically (up/down)

Pre-stretch rollers apply consistent film tension

Controlled Layering

The machine applies multiple wrap layers at critical load zones (base and top).Cycle Completion

The machine stops automatically once the programmed wrap cycle finishes.Film Cut and Load Removal

The operator cuts the film and removes the wrapped load.

This hybrid workflow ensures repeatable quality while maintaining operational flexibility.

Types of Semi Automatic Wrapper Machines and Their Applications

1. Turntable Semi Automatic Wrapper

Best for: Standard pallets, cartons, and uniform loads

Advantages:

Compact footprint

Cost-effective

Easy to install and operate

2. Rotary Arm Semi Automatic Wrapper

Best for: Lightweight, unstable, or tall loads

Advantages:

No load rotation

Higher stability

Faster cycle times

3. Mobile / Portable Wrapper

Best for: Large or immovable loads

Advantages:

Wraps products in fixed locations

Ideal for heavy machinery and oversized goods

4. Conveyor-Integrated Semi Automatic Wrapper

Best for: Production lines with moderate automation

Advantages:

Line synchronization

Reduced handling

Scalable toward full automation

Why Manufacturers Choose Professional-Grade Machines

Manufacturers prefer professional-grade semi automatic wrapper machines over low-cost alternatives because they offer:

Industrial-duty components

Reliable film tension control

Higher uptime and service life

Compliance with safety standards

Strong after-sales support

Low-cost machines often result in higher downtime, inconsistent wrapping, and hidden maintenance costs.

Buying Considerations for Industrial Buyers

When evaluating a semi automatic wrapper machine, buyers should assess:

Load size, weight, and stability

Daily wrapping volume

Film type compatibility

Floor layout and power availability

Operator skill level

After-sales support and spare parts availability

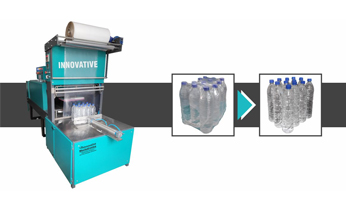

Semi Automatic Wrapper Machines from Innovative WrapTech Pvt. Ltd. offer:

A practical entry point into smart automation

Proven industrial reliability

Strong ROI and scalability

Safe, efficient, and consistent packaging

If your operation requires flexibility, controlled automation, and future-ready packaging without full automation costs, this machine category is a strategic investment.

Frequently Asked Questions (FAQ)

1. What is a semi automatic wrapper machine?

A semi automatic wrapper machine is an industrial packaging solution that automatically wraps products or pallets with stretch film while requiring an operator to load the product and start the wrapping cycle.

2. How does a semi automatic wrapper machine benefit modern manufacturing?

It improves packaging consistency, reduces labor effort, lowers film consumption, enhances load stability, and supports smart automation without the cost of full automation.

3. What types of loads can be wrapped using a semi automatic wrapper machine?

These machines can wrap cartons, bags, drums, bundles, and palletized loads of various sizes and weights, depending on machine configuration.

4. What safety features are included in semi automatic wrapper machines?

Standard safety features include emergency stop buttons, guarded moving parts, overload protection, low-voltage control circuits, and compliance with CE and ISO safety standards.

5. How quickly can manufacturers achieve ROI with a semi automatic wrapper machine?

Most manufacturers achieve return on investment within 12 to 24 months through reduced labor costs, lower stretch film usage, and minimized transport damage.