Advantages of Coil Wrapping Machine for Coil Manufacturers

Advantages of Coil Wrapping Machine for Coil Manufacturers

In today’s competitive industrial market, coil manufacturers need reliable, efficient, and safe packaging solutions. Coil wrapping machines provide a modern answer by automating the wrapping process, protecting products, and reducing material waste. By investing in these machines, manufacturers can increase productivity, lower operational costs, and improve overall safety in their facilities.

What is a Coil Wrapping Machine?

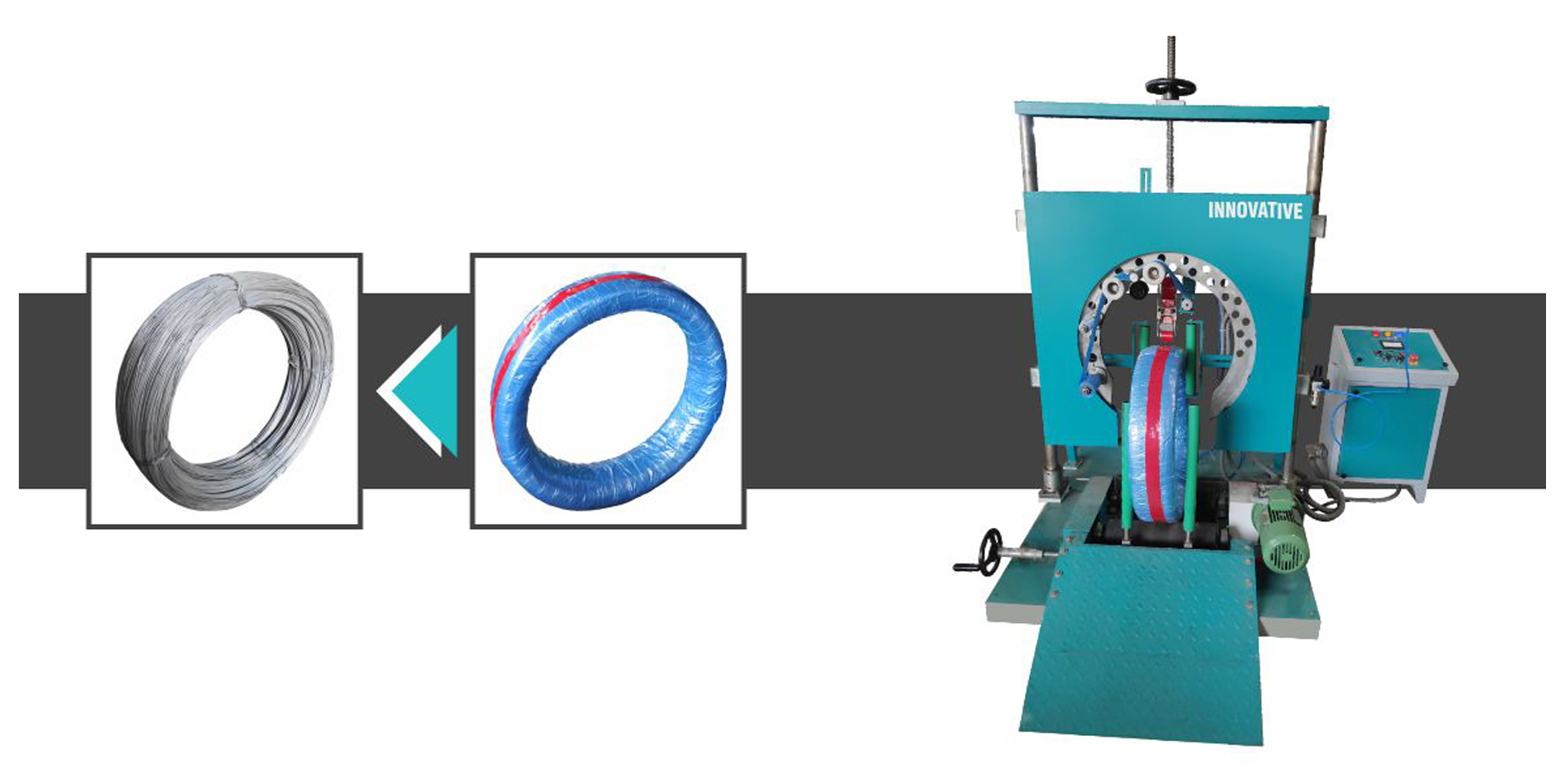

A coil wrapping machine is an industrial device designed to wrap coils of metal, wire, or steel with stretch film or protective materials. Unlike manual wrapping, these machines ensure consistent coverage, proper tension, and secure packaging for every coil.

Key purposes include:

Protecting coils from dust, moisture, and mechanical damage

Stabilizing loads for transportation and storage

Reducing manual labor and packaging time

Key Advantages of Coil Wrapping Machines

Coil Wrapping Machine Benefits to manufacturers:

1. Enhanced Efficiency

Automatic wrapping allows manufacturers to wrap coils faster and more consistently than manual methods. High-speed machines can wrap multiple coils in minutes, boosting production throughput.

2. Cost Savings

Machines optimize film usage and reduce waste, helping manufacturers save 20–30% on packaging material. Lower labor requirements also cut operational costs significantly.

3. Improved Product Protection

Proper wrapping prevents rust, dust, scratches, and other damage, ensuring coils reach clients in perfect condition. Consistent tension avoids coil deformation or instability during transport.

4. Operator Safety

Automating the wrapping process reduces physical strain on workers and minimizes the risk of accidents. Most machines include safety interlocks and emergency stop systems.

5. Customizable Wrapping Programs

Modern machines allow programmable wrapping cycles, adjusting speed, tension, and layers based on coil size and weight. This flexibility ensures perfect protection for all coil types.

6. Sustainability and Waste Reduction

Precise wrapping reduces excess film usage, contributing to eco-friendly manufacturing practices. Manufacturers can meet sustainability goals without sacrificing efficiency.

Types of Coil Wrapping Machines

Choosing the right type depends on the coil size, weight, and production requirements:

Turntable Wrappers: Coils rotate on a turntable while film applies evenly. Ideal for small to medium-sized coils.

Rotary Arm Wrappers: Suitable for heavy or large coils; the arm moves around a stationary coil.

Robotic Wrappers: Fully automated and programmable for high-speed, high-volume operations.

Best Practices for Maximizing Efficiency

Use High-Quality Stretch Film: Reduces breakage and improves coil protection.

Program Machines According to Coil Size: Avoids overuse of film and saves costs.

Regular Maintenance: Lubricate moving parts, check sensors, and replace worn rollers.

Operator Training: Skilled operators prevent errors and maximize machine performance.

Monitor Performance Metrics: Track wrapping speed, material usage, and downtime to improve efficiency.

Coil Wrapping Machine Benefits

Steel and Metal Manufacturers: Protect heavy coils during storage and transport.

Wire and Cable Manufacturers: Ensure coils arrive without tangling or damage.

E-commerce and Logistics: Handle high-volume shipments efficiently.

Automotive and Machinery Suppliers: Protect precision coils for industrial use.

Conclusion

Investing in a coil wrapping machine gives manufacturers higher efficiency, lower costs, safer operations, and superior coil protection. By choosing the right type, following best practices, and using quality materials, coil manufacturers can optimize their packaging processes and maintain a competitive edge in the market.

FAQs

1. How much can manufacturers save with a coil wrapping machine?

Savings depend on film usage, labor costs, and production volume, typically 20–30% on materials and up to 50% on labor.

2. Can coil wrapping machines handle large or heavy coils?

Yes, rotary arm and robotic wrappers are designed for heavy, oversized, or irregular coils.

3. How fast can a coil wrapping machine wrap a coil?

Standard machines wrap coils in 1–3 minutes, while high-speed models can do it in under a minute.

4. What maintenance is required?

Lubricate moving parts, check tension systems, clean sensors, and replace worn rollers regularly.

5. Are coil wrapping machines safe for operators?

Yes. Machines include emergency stops, safety interlocks, and protective barriers to prevent accidents.