The Automation Advantage: A Practical Path to Upgrading Your Box Wrapping Process

Modern Box Wrapping Automation: A Step-by-Step Upgrade Guide

In high-volume packaging environments, manual box wrapping slows output, increases material waste, and exposes operations to inconsistency. Automated box wrapping systems solve these problems by delivering speed, repeatability, and control. At Innovative WrapTech Pvt. Ltd., we see box wrapping automation as a practical upgrade—not a disruptive overhaul—because it improves productivity without compromising flexibility.

This guide explains how automated box wrapping machines work, why they matter, and how to select the right system for real industrial operations.

What Is an Automated Box Wrapping Machine?

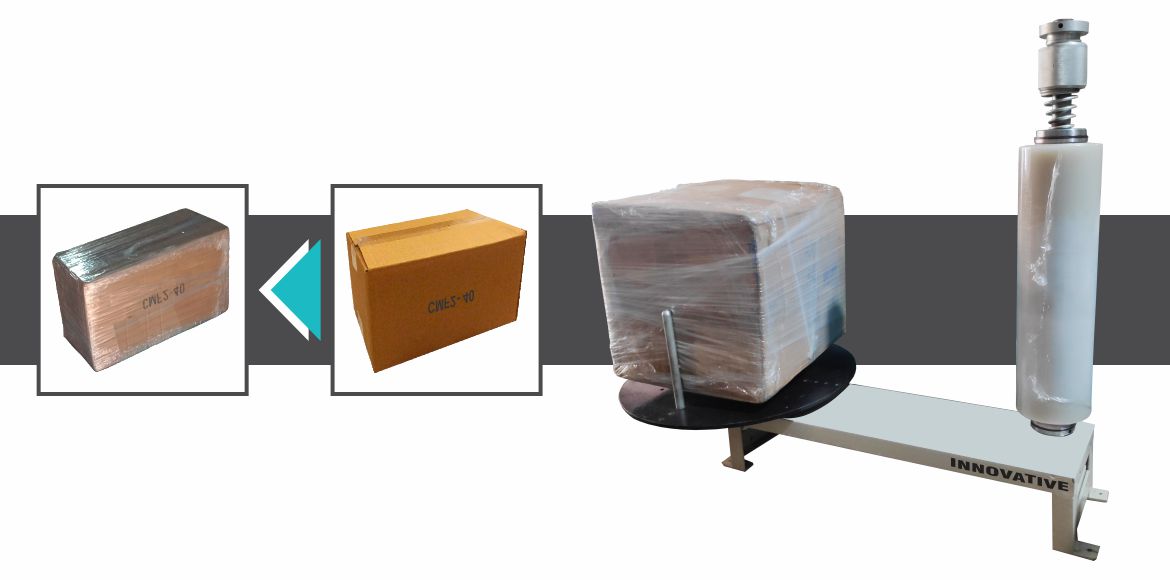

An automated box wrapping machine applies stretch film, shrink film, or paper-based wrapping material around cartons or boxed products in a controlled, repeatable process. The machine replaces manual wrapping by standardizing tension, coverage, and sealing while reducing labor dependency.

These machines serve as a final-stage packaging solution, preparing boxes for storage, palletizing, or shipment.

How an Automated Box Wrapping Machine Works

Step 1: Box Infeed

The operator places the box manually or feeds it via conveyor into the wrapping zone.

Step 2: Box Detection and Alignment

Sensors detect box dimensions and align it correctly for uniform wrapping.

Step 3: Film or Material Dispensing

The machine dispenses wrapping material at preset tension and overlap levels.

Step 4: Wrapping Cycle Execution

The box rotates, or the wrapping arm moves around the box, applying material evenly on all sides.

Step 5: Cutting and Sealing

An integrated cutting and sealing system completes the wrap cleanly.

Step 6: Box Discharge

The wrapped box exits the machine, ready for palletizing or shipping.

Why an Automated Box Wrapping Process Upgrade Is Essential in Modern Industry

Manual wrapping introduces:

Inconsistent load containment

High labor costs

Excessive film usage

Operator fatigue and injury risks

Automation delivers measurable advantages:

Up to 40% reduction in wrapping material consumption

Consistent packaging quality

Higher throughput with fewer operators

Improved workplace safety

Predictable packaging costs

Types of Box Wrapping Machines and When to Use Them

1. Semi-Automatic Box Wrappers

Ideal for low to medium volumes with frequent size changes.

2. Fully Automatic Box Wrappers

Best for continuous production lines requiring minimal operator involvement.

3. Rotary Arm Box Wrappers

Used when boxes are unstable or lightweight and must remain stationary.

4. Conveyorized Inline Systems

Integrated into high-speed packaging lines for zero-touch operations.

How to Choose the Right Box Wrapping Machine

Key Selection Factors

Daily box volume

Box dimensions and weight

Required wrap quality

Level of automation

Floor space availability

Budget and ROI expectations

Innovative WrapTech Pvt. Ltd. recommends prioritizing long-term efficiency over initial cost.

Common Operational Problems and How Automation Solves Them

Problem: Uneven or loose wrapping

Solution: Controlled tension and repeatable wrap programs.

Problem: High film consumption

Solution: Pre-stretch technology and optimized overlap.

Problem: Operator fatigue

Solution: Reduced manual handling and ergonomic operation.

Problem: Production bottlenecks

Solution: Consistent cycle times and higher throughput.

Frequently Asked Questions (FAQs)

1. Can automated Box Wrapping Process Upgrade handle different box sizes?

Yes. Adjustable guides and sensors allow fast changeovers.

2. Is automation suitable for small operations?

Yes. Semi-automatic machines provide quick ROI with minimal investment.

3. Does automation damage fragile boxes?

No. Controlled tension prevents crushing or deformation.

4. How soon can I expect ROI?

Most operations recover costs within 12–18 months.

5. Can machines integrate with conveyors?

Yes. Fully automatic systems support inline integration.