Seal Savvy: A Practical Guide to Resolving Common Automatic L-Sealer Challenges

Automatic L-Sealer Troubleshooting: Expert Tips for Industrial Packaging

Automatic L-sealers are essential machines in modern packaging operations, providing precise, fast, and consistent sealing for cartons, bags, pouches, and film-wrapped products. However, inefficient setup, poor maintenance, or improper material selection can cause downtime, inconsistent seals, and increased operational costs.

This guide explains what automatic L-sealers are, how they work, how to optimize performance, and provides technical insights and operational guidance to help buyers make informed decisions.

What Is an Automatic L-Sealer and How Does It Work?

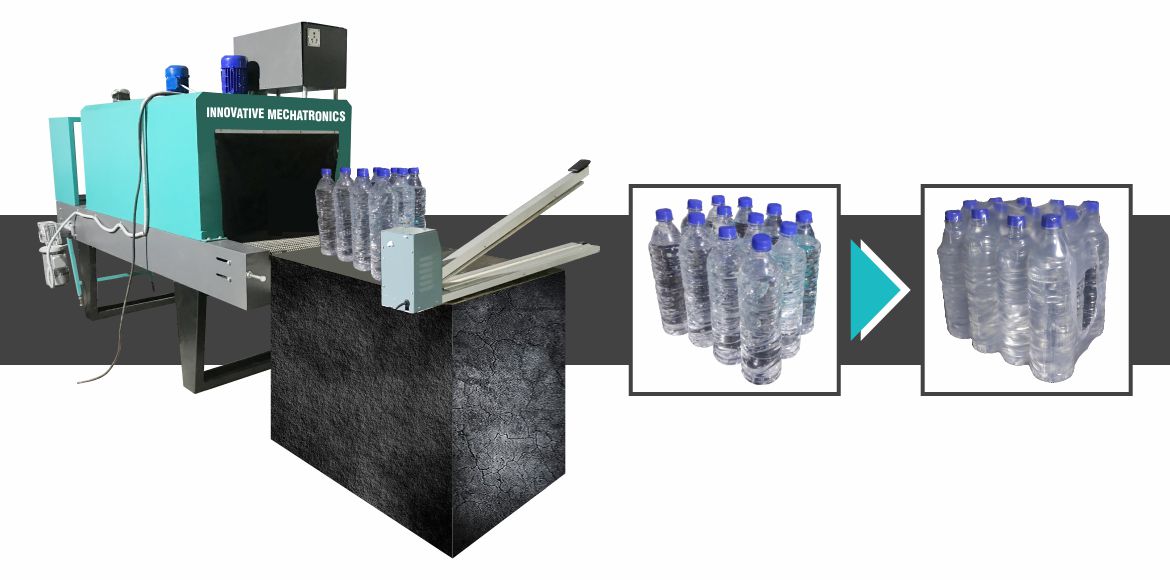

An automatic L-sealer is a film sealing machine that wraps and seals products with heat-shrink or stretch films, using an L-shaped sealing bar. Its purpose is to create strong, tamper-proof seals while improving throughput and reducing labor.

Step-by-step Operation:

Product Loading – The product enters the sealing area, manually or via conveyor.

Film Alignment – Heat-shrink or plastic film is drawn over the product.

L-Bar Sealing – The L-shaped bar descends to seal the film along two edges simultaneously.

Film Cutting – Integrated knives cut excess film automatically.

Product Exit – The sealed product moves to shrink tunnels (if applicable) or directly to packaging conveyors.

Optional Shrink Tunnel – Film shrinks tightly around the product under controlled heat.

Key Takeaway: Automatic L-sealers replace inconsistent manual sealing, reduce labor costs, and ensure uniform packaging quality.

Why Are Automatic L-Sealer Troubleshooting Guide Important in Industrial Operations?

Productivity: Speeds up packaging lines with continuous operation.

Quality: Provides uniform, professional seals for consumer and industrial products.

Safety: Eliminates operator exposure to sharp knives and hot surfaces.

Cost Efficiency: Reduces film waste and labor compared to manual sealing.

Types and Variants of Automatic L-Sealers

| Type | Use Case | Advantages | Notes |

|---|---|---|---|

| Tabletop Automatic L-Sealer | Small-volume operations | Compact, cost-effective | Limited throughput |

| Floor-Mounted Conveyor L-Sealer | Medium-to-high volume | Continuous flow, integrates with conveyor systems | Requires factory floor space |

| Servo-Driven L-Sealer | High-precision, variable-sized products | Faster cycle times, programmable | Higher upfront cost |

| Inline Shrink L-Sealer | Packaging + shrink wrap in one line | Reduces handling | Requires precise temperature and film control |

Usage Tip: Choose based on volume, product size, film type, and available space.

Standard Industrial Specifications

Sealing Bar Length: 400–1200 mm

Cycle Time: 2–10 seconds per seal

Film Compatibility: Polyethylene, PVC, polypropylene, laminated films

Power Supply: 220–440V / 3-phase / 50–60Hz

Throughput: 20–120 packs/min (depending on model)

Construction: Stainless steel or coated mild steel

Industries and Applications

Food & Beverage: Snack packs, bakery, frozen foods

Pharmaceuticals: Bottles, blister packs, medical kits

Consumer Goods: Electronics, cosmetics, home appliances

E-commerce & Logistics: Multipacks, subscription boxes

How to Choose the Right Automatic L-Sealer

Consider:

Production Volume – Low-volume tabletop or medium/high-volume inline systems.

Material Type – Film compatibility and thickness.

Automation Level – Manual loading, semi-automatic, or fully inline conveyor.

Space Constraints – Floor footprint for inline machines.

Budget & ROI – Higher initial investment pays off via labor savings, reduced waste, and faster throughput.

Manual vs Automatic L-Sealers

| Feature | Manual Sealing | Automatic L-Sealer |

|---|---|---|

| Labor | High | Low |

| Seal Consistency | Variable | Uniform |

| Speed | Slow | High-speed production |

| Film Waste | Higher | Optimized |

| Safety | Risk of burns & cuts | Protected with interlocks |

Observation: Industrial buyers prefer automatic machines for consistency, efficiency, and safety.

Common Operational Problems and Solutions

Wrinkled or Weak Seals – Adjust temperature and film tension.

Film Jamming – Clean rollers and check film feed alignment.

Cycle Delays – Inspect sensors and L-bar carriage movement.

Operator Injuries – Ensure interlocks and emergency stop functionality.

Inconsistent Shrink Wrap – Calibrate tunnel temperature and conveyor speed.

Summary

Automatic L-sealers are essential tools for industrial packaging, ensuring consistent, safe, and high-quality seals while reducing labor and material costs. Aftermarket support, proper installation, maintenance, and automation features are key to long-term productivity.

If your operation demands speed, reliability, and professional-grade packaging, an Automatic L-Sealer Troubleshooting Guide from a trusted provider like Innovative WrapTech Pvt. Ltd. ensures high ROI and operational excellence.

FAQs – Automatic L-Sealer

1. What types of products can an automatic L-sealer handle?

Automatic L-sealers can package cartons, pouches, shrink-wrapped boxes, electronics, food items, and consumer goods with consistent, high-quality seals.

2. How does an automatic L-sealer improve productivity?

It automates sealing and cutting, reducing manual labor, ensuring uniform seals, and increasing throughput compared to manual methods.

3. Can an L-sealer work with different film types?

Yes, as long as the film is compatible with the machine’s L-bar and temperature settings, including polyethylene, PVC, and polypropylene films.

4. Are Automatic L-Sealer Troubleshooting Guide safe for operators?

Yes. Safety interlocks, emergency stops, and protective guards prevent accidents, burns, and contact with moving parts.

5. How do I maintain consistent seal quality?

Regularly calibrate the L-bar temperature, film tension, and alignment. Clean rollers and cutting blades daily to prevent jams or weak seals.

6. What industries commonly use L-sealers?

Food & beverage, pharmaceuticals, cosmetics, electronics, e-commerce, and logistics industries rely on L-sealers for efficient, professional packaging.

7. How do I choose the right L-sealer for my operation?

Consider production volume, product size, film type, automation level, available space, and budget. Semi-automatic models suit low volume; inline conveyor models suit high volume.

8. Why invest in industrial-grade L-sealers over low-cost alternatives?

Industrial-grade machines offer durability, reliability, consistent quality, and safety, delivering higher ROI through reduced downtime, labor savings, and minimized film waste.