Mastering the Wrap: Avoiding Costly Errors with Your Semi-Automatic Pallet Wrapper

Mastering the Wrap: Avoiding Costly Errors with Your Semi-Automatic Pallet Wrapper

What Is a Semi-Automatic Pallet Wrapping Machine?

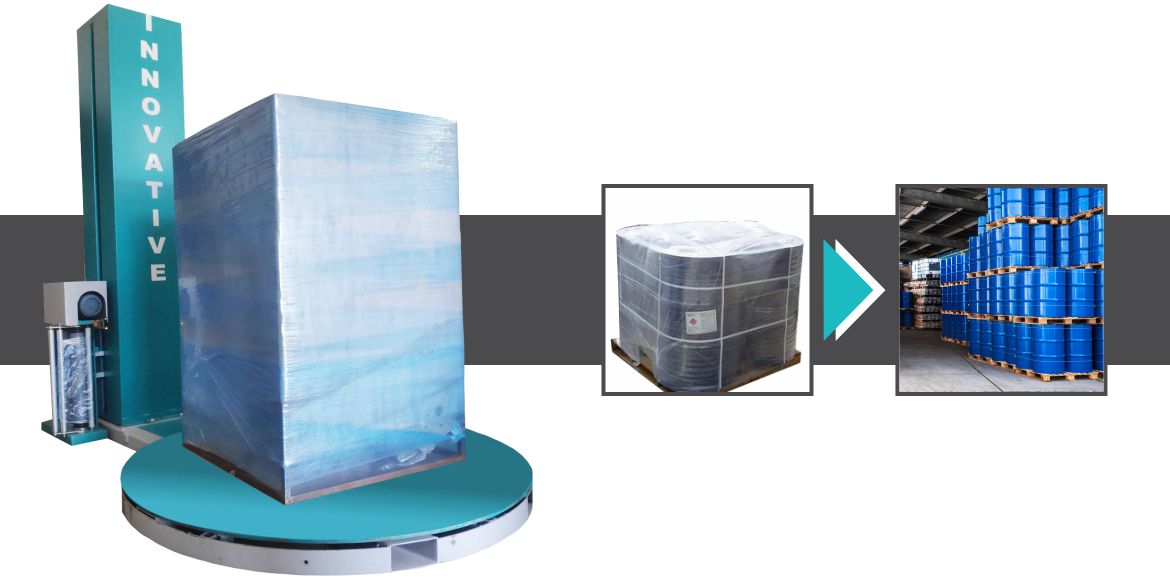

A semi-automatic pallet wrapping machine secures palletized loads using stretch film while requiring minimal operator involvement. The operator places the pallet on the turntable or base, attaches the film, and starts the cycle. The machine then wraps the load with controlled tension, consistent overlap, and uniform coverage.

Manufacturers use semi-automatic pallet wrappers to improve load stability, reduce film waste, and eliminate inconsistent manual wrapping.

Why Is This Machine Important in Modern Industrial Operations?

Semi-automatic pallet wrappers help manufacturers:

Eliminate load instability during transport

Improve packaging consistency

Increase worker safety and productivity

Lower long-term packaging costs

Scale operations without full automation investment

This machine acts as a bridge between manual wrapping and fully automatic systems.

Types and Variants of Semi-Automatic Pallet Wrappers

1. Turntable Pallet Wrapper

Best for: Standard, stable loads

Why use it: Cost-effective and easy to operate

2. Low-Profile Turntable Wrapper

Best for: Pallet jacks and forklifts

Why use it: Easy loading without ramps

3. Extended Height Pallet Wrapper

Best for: Tall pallet loads

Why use it: Ensures full load coverage

4. Semi-Automatic Pallet Wrapper with Pre-Stretch

Best for: High film cost environments

Why use it: Reduces film usage by up to 30–50%

5. Ramp-Based Wrapper

Best for: Non-forklift loading

Why use it: Simple manual pallet access

Industries and Real-World Applications

Manufacturing & Warehousing

FMCG & Consumer Goods

Food & Beverage

Pharmaceuticals

Logistics & Distribution Centers

Building Materials

Paper & Printing

How Buyers Can Choose the Right Model

1. Load Size & Weight

Choose heavy-duty turntables for dense or heavy pallets.

2. Film Consumption Goals

Select powered pre-stretch models to reduce film costs.

3. Production Volume

Low to medium throughput works best with semi-automatic machines.

4. Automation Level

Upgrade to full automation when operator handling becomes a bottleneck.

5. Budget

Semi-automatic machines offer the best ROI for growing operations.

Best Practices for Installation, Operation, and Maintenance

Installation

Place on a level surface

Ensure stable power supply

Operation

Train operators on control panel settings

Use recommended stretch films

Maintenance

Clean turntable and rollers daily

Inspect belts, chains, and sensors

Schedule preventive servicing

Conclusion

A semi-automatic pallet wrapper helps businesses master the wrap, avoid costly errors, and protect palletized goods. It delivers the ideal balance of automation, cost efficiency, and operational control—making it an essential tool for modern industrial packaging.

Frequently Asked Questions (FAQs) – Semi-Automatic Pallet Wrapping Machine

Q1. What is a semi-automatic pallet wrapping machine used for?

A semi-automatic pallet wrapping machine secures palletized loads with stretch film to improve load stability, reduce product damage during transport, and minimize stretch film waste compared to manual wrapping.

Q2. How does a semi-automatic pallet wrapper reduce packaging costs?

The machine uses controlled film tension and optional pre-stretch systems to reduce film consumption, lowers labor effort, and minimizes load failures, which together reduce overall packaging and logistics costs.

Q3. Which industries commonly use semi-automatic pallet wrappers?

Industries such as FMCG, food and beverage, pharmaceuticals, manufacturing, warehousing, logistics, paper, and building materials widely use semi-automatic pallet wrapping machines.

Q4. What is the difference between semi-automatic and manual pallet wrapping?

Semi-automatic pallet wrapping delivers consistent wrap quality, better load stability, improved safety, and lower film usage, while manual wrapping depends heavily on operator skill and leads to higher labor fatigue and material waste.

Q5. What factors should buyers consider when selecting a semi-automatic pallet wrapper?

Buyers should consider pallet weight and size, required wrapping speed, film type, pre-stretch capability, available floor space, automation needs, and budget to choose the right model.