Wrapping Up Waste: How Machines Can Revolutionize Packaging for a Circular Economy

Wrapping Up Waste: How Machines Can Revolutionize Packaging for a Circular Economy

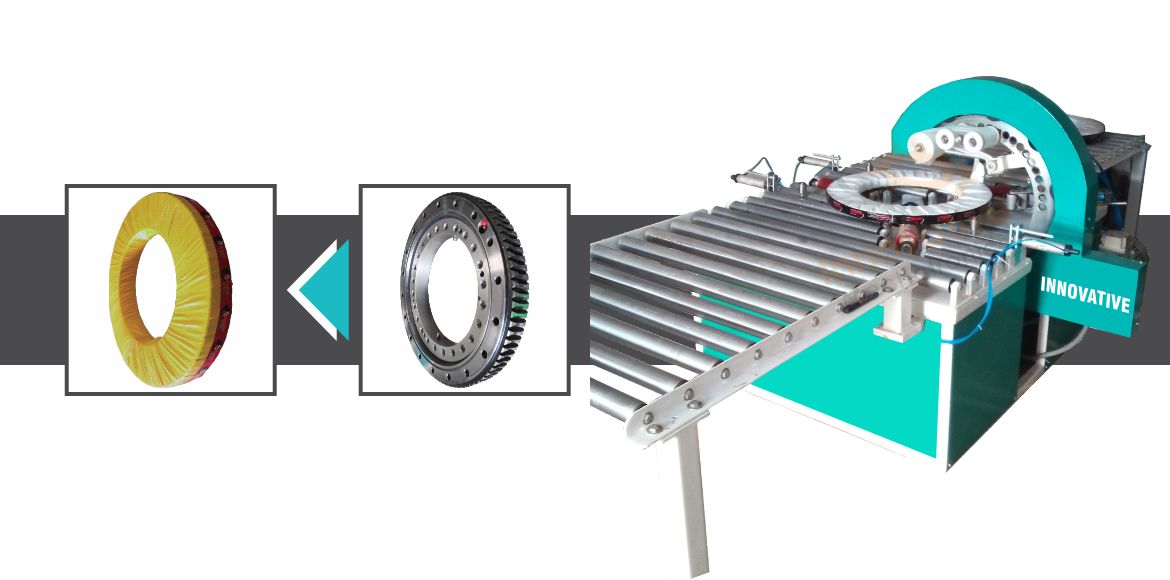

In modern manufacturing, packaging waste is more than an environmental concern—it’s an operational challenge. Innovative WrapTech Pvt. Ltd. provides industrial-grade packaging machinery that transforms how companies handle stretch film, shrink wrap, and palletized loads, enabling a circular economy while optimizing efficiency and cost.

These machines help factories minimize material waste, improve load stability, and reduce energy usage, aligning packaging operations with sustainable business practices.

What is a Circular Economy Packaging Machines?

A circular economy packaging machine is designed to secure, wrap, and recycle packaging materials efficiently. By integrating precision wrapping, controlled tension systems, and reusable or recyclable films, these machines:

Reduce single-use film consumption

Lower operational waste

Ensure pallets, rolls, and boxes remain protected during transport

Enable easy recovery of packaging materials for reuse

These machines are central to sustainable manufacturing operations, particularly in sectors like FMCG, electronics, automotive, and e-commerce logistics.

Step-by-Step Technical Operation

Industrial packaging machines operate with precision and automation. Here’s a stepwise technical overview:

Load Placement

Place pallet, roll, or product stack on the machine platform.

For conveyor-integrated models, the load is automatically aligned.

Pre-Programmed Settings Activation

Operators select wrapping programs based on load size, weight, and film type.

Film tension, pre-stretch percentage, and wrap count are digitally configured.

Film Application

The machine feeds stretch or shrink film from the roll.

Wrapping Cycle Execution

Rotating turntables or orbital arms wrap the load evenly.

Edge and corner protection is applied as needed.

Film Cutting and Sealing

Automatic cutting devices separate the film.

Sealing or tuck mechanisms finish the wrap for maximum load integrity.

Load Completion & Recyclable Recovery

Wrapped pallets are ready for storage or shipment.

Optional film recovery modules collect scraps for reuse or recycling.

Best Practices for Installation, Operation, and Maintenance

Installation

Place the machine on a level concrete foundation.

Ensure adequate space around the unit for operation and maintenance.

Connect to stable power supply and grounding system.

Validate integration with conveyors, WMS, or ERP if required.

Daily Operations

Inspect film rolls and replace if damaged.

Check tension rollers, safety guards, and sensors.

Ensure the load is centered and the machine is free of obstructions.

Run a test cycle before full production.

Weekly Maintenance

Clean all moving parts and remove dust or debris.

Lubricate gears, chains, and bearings per manufacturer guidelines.

Inspect pre-stretch rollers for wear and tear.

Verify software calibration and wrapping program accuracy.

Long-Term Maintenance

Replace worn belts, rollers, and motors on a scheduled basis.

Update software and firmware to enable smart factory compatibility.

Conduct a full safety audit to comply with ISO 12100 / CE / OSHA standards.

Perform load testing for quality assurance and regulatory compliance.

Why Manufacturers Prefer Circular Economy Packaging Machines

Industrial-grade motors, PLC systems, and tension control ensure consistent performance.

Low-cost alternatives often fail in high-volume or heavy-load operations.

Durable machines reduce maintenance downtime and protect operator safety.

Professional machines enable smart factory integration, supporting future scalability.

Future Trends and Automation Possibilities

IoT Integration: Real-time monitoring of wrapping cycles, load status, and film consumption.

AI-Powered Optimization: Automatic adjustment of film tension and wrap cycles.

Robotic Handling: Fully automated loading, wrapping, and palletizing.

Sustainable Materials: Biodegradable or recyclable films tailored for circular economy practices.

Predictive Maintenance: Data-driven alerts to prevent failures and maximize uptime.

Frequently Asked Questions (FAQs)

Q1. What is a circular economy packaging machine?

A circular economy packaging machine secures pallets, rolls, and boxes while minimizing film waste. It supports reuse or recycling of materials and ensures load stability and protection during storage and transport.

Q2. How do these machines reduce packaging waste?

By using precise tension control, pre-stretch systems, and optimized wrapping programs, these machines reduce film consumption, minimize rework, and allow recyclable or reusable materials to be recovered efficiently.

Q3. Which types of machines are available and when should each be used?

Rotary Turntable Wrappers: Standard pallets and boxes – compact and cost-effective.

Rotary Arm / Orbital Wrappers: Fragile or irregular loads – prevents tipping.

Automatic Pre-Stretch Systems: Heavy industrial pallets – reduces film usage up to 40%.

Shrink Tunnel Machines: Cylindrical or prismatic products – tamper-proof wraps.

Robotic / Gantry Wrappers: Mixed or custom pallets – high-speed and fully automated.

Q4. What are the key maintenance practices for industrial packaging machines?

Daily: Inspect film rolls, sensors, and safety guards.

Weekly: Lubricate bearings, clean moving parts, check calibration.

Long-term: Replace worn components, update software, perform full safety audits.

Q5. Why should manufacturers choose professional-grade machines over low-cost alternatives?

Professional machines offer industrial-grade components, consistent performance, reduced downtime, operator safety, and compatibility with smart factory integration—ensuring higher ROI and reliability in high-volume operations.