Handle with Extreme Care: Tailored Pallet Packing Strategies for Electronics and Glassware

What Is Tailored Pallet Packing for Electronics and Glassware?

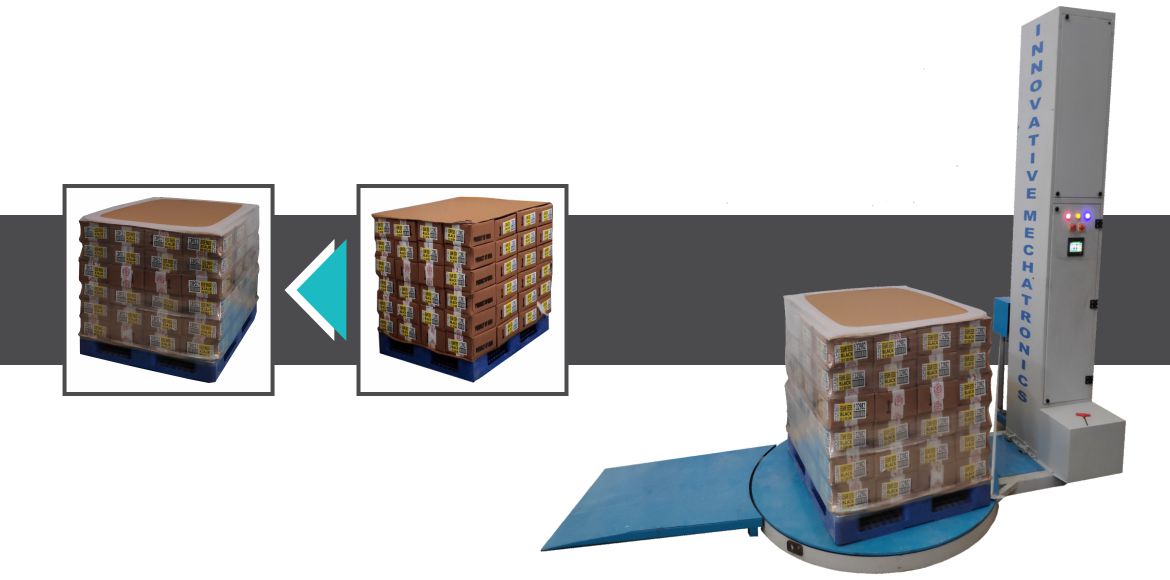

Tailored pallet packing is a specialized palletizing and wrapping approach designed to protect fragile, high-value products such as electronics and glassware during storage and transportation. This system uses controlled tension, cushioning materials, and precise wrapping patterns to prevent shock, vibration, static discharge, and breakage.

Manufacturers customize pallet packing parameters based on product weight, fragility, surface sensitivity, and stacking behavior, ensuring maximum protection without over-packing.

Tailored pallet packing is a specialized palletizing and wrapping approach designed to protect fragile, high-value products such as electronics and glassware during storage and transportation. This system uses controlled tension, cushioning materials, and precise wrapping patterns to prevent shock, vibration, static discharge, and breakage.

Manufacturers customize pallet packing parameters based on product weight, fragility, surface sensitivity, and stacking behavior, ensuring maximum protection without over-packing.

How Does Tailored Fragile Pallet Packing Strategies ?

Product Assessment

Operators analyze product dimensions, fragility level, surface sensitivity, and stacking limits.Pallet Preparation

The system selects the correct pallet size and applies slip sheets, foam pads, or anti-static layers if required.Load Positioning

The operator or automated system positions cartons, crates, or trays evenly to distribute weight.Protective Layering

The system adds corner boards, edge protectors, air cushions, or ESD-safe materials.Controlled Wrapping

The pallet wrapper applies stretch or shrink film with low, progressive tension to avoid crushing or cracking.Stabilization & Sealing

The machine reinforces the top and bottom wraps to lock the load securely.Final Inspection

Sensors or operators verify load stability before dispatch.

Why Is Fragile Pallet Packing Strategies Packing System Important in Modern Industrial Operations?

Modern supply chains demand damage-free delivery, compliance, and cost efficiency. Tailored pallet packing:

Reduces product damage and returns

Protects sensitive electronic components from ESD

Prevents glass breakage during transit

Improves warehouse handling safety

Enhances brand reputation and customer trust

Industries can no longer rely on generic packing methods for fragile goods.

Types of Fragile Pallet Packing Strategies Systems and Their Use Cases

1. Low-Tension Stretch Wrapping Systems

Use for lightweight electronics and fragile glass products.

2. ESD-Safe Pallet Wrapping Machines

Use for circuit boards, semiconductors, and electronic assemblies.

3. Shrink Wrapping Systems with Controlled Heat

Use for glassware requiring tight load containment.

4. Cushion-Assisted Pallet Packing Systems

Use for high-impact risk transportation.

5. Fully Automated Pallet Packing Lines

Use for high-volume electronics and glass manufacturing plants.

Safety Standards and Operator Protection

These systems comply with:

CE Safety Standards

ISO Packaging Guidelines

OSHA Workplace Safety Norms

ESD Protection Standards (IEC 61340)

Operator safety features include:

Emergency stop buttons

Guarded moving parts

Anti-static grounding systems

Automatic fault detection

Tailored pallet packing for electronics and glassware delivers maximum protection, regulatory compliance, and operational efficiency, making it a critical investment for modern manufacturing and logistics operations.

1. What is tailored pallet packing for electronics and glassware?

Tailored pallet packing is a customized packaging method that uses controlled wrapping tension, cushioning materials, and protective layers to safely secure fragile electronics and glassware during storage and transportation.

2. How does tailored pallet packing protect fragile products?

The system applies low and progressive film tension, adds corner and edge protection, and uses ESD-safe or cushioning materials to prevent breakage, vibration damage, and static discharge.

3. Which industries benefit most from tailored pallet packing?

Industries such as electronics manufacturing, semiconductor production, glassware manufacturing, medical equipment packaging, and export logistics benefit the most from this solution.

4. How is tailored pallet packing better than manual packing?

Tailored pallet packing provides consistent load stability, reduces product damage, lowers labor dependency, and ensures compliance with safety and quality standards, unlike manual packing.

5. What factors should buyers consider before choosing a pallet packing system?

Buyers should consider load capacity, product fragility, automation level, type of packing material, available space, and budget to select the right system.