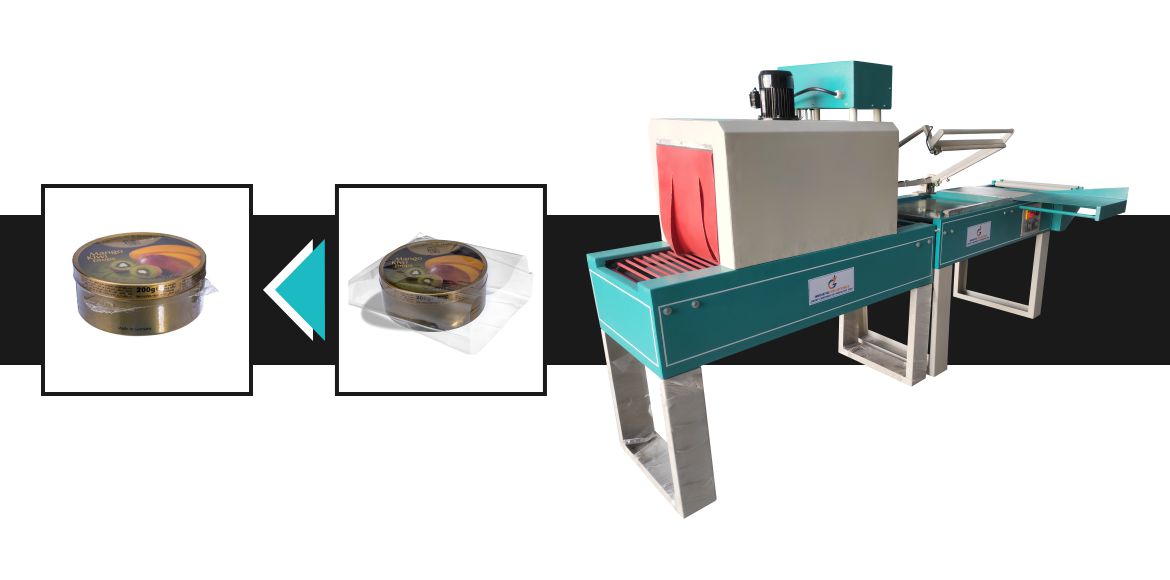

Automatic L-seal cutting machine is a fully automatic unmanned L sealing cutter, widely used for lot production pipelining with high efficiency. The machine is equipped with an auto film feeding & perforating device and adjustable product infeed conveying table in order to meet different requirements from different products.

Fully automatic L-sealers are high-speed L-sealing solutions for wrapping using polyolefin film. The automatic L-sealers can be used in combination with shrink tunnels.

automatic L-sealers are ideal for high speed, providing excellent performance and value for money.

The complete system consists of a fully automatic L-sealing machine and a separate heat shrink tunnel.

The speed of the system is up to 25 packs per minute. The machine is fully automatic and an operator is only required for loading packets, monitoring, and film changing.

L-Sealer Wire Cable Machine

The L-Sealer Wire Cable Machine is an industrial packaging solution designed to securely and uniformly seal wire and cable bundles. Using an L-shaped sealing mechanism, it ensures airtight, tamper-proof, and professional-quality packaging, protecting products during storage and transportation.

It eliminates the need for manual binding or wrapping, reduces labor costs, and maintains consistent packaging quality in high-volume production environments.

How the Machine Works

Bundle Preparation

Wire or cable bundles are gathered and aligned on the infeed platform.Positioning & Alignment

The machine’s guides and sensors align the bundle precisely for accurate sealing.Sealing Process

The L-shaped sealing arm moves along the bundle edges.

Heat or pressure is applied to seal the packaging film or shrink wrap, securing the bundle.

Cutting & Trimming

Excess film is trimmed automatically, leaving a clean, uniform seal.Discharge

The sealed wire or cable bundles exit via the outfeed platform, ready for storage, shipping, or further processing.

Importance in Modern Industrial Operations

Productivity: High-speed sealing increases output without extra labor.

Efficiency: Precise sealing reduces material waste and rework.

Safety: Minimizes operator handling of heavy or long bundles.

Protection: Prevents tangling, surface damage, and contamination.

Consistency: Maintains professional packaging quality for every bundle.

Key Technical Features & Operational Benefits

Adjustable sealing temperature & speed – Handles different film types and thicknesses.

PLC or microprocessor controls – Ensures precise and repeatable sealing cycles.

Safety guards and emergency stops – Protect operators during operation.

Durable industrial construction – Provides long-term reliability in high-volume environments.

Compact footprint – Fits inline in automated production facilities.

How to Choose the Right Model

Capacity: Match machine speed with production requirements.

Bundle Size & Material: Ensure compatibility with wire or cable dimensions.

Automation Level: Manual, semi-automatic, or fully automatic based on throughput.

Budget & ROI: Factor in labor savings, material efficiency, and reduced rework.

Integration: Check for compatibility with existing conveyors or production lines.

Best Practices for Installation, Operation & Maintenance

Installation:

Place on a level, vibration-free surface.

Ensure proper electrical grounding.

Align infeed and outfeed conveyors.

Operation:

Set correct temperature, pressure, and sealing speed.

Train operators on safety features and PLC/HMI controls.

Maintain consistent feed rate for uniform sealing.

Maintenance:

Daily: Clean sealing bars, sensors, and conveyor areas.

Weekly: Inspect heating elements, cutting knives, and moving parts.

Monthly / Long-term: Lubricate motors, calibrate sensors, and perform preventive maintenance.

Safety Standards & Compliance

CE and ISO 12100 certified

Emergency stop buttons and safety guards

IEC electrical safety standards

Lockout-Tagout (LOTO) compatible

These measures ensure operator protection and safe industrial operation.

FAQs

1. What is an L-Sealer Wire Cable Machine?

It is an industrial packaging machine designed to securely and uniformly seal wire and cable bundles, ensuring protection, safe handling, and consistent packaging quality during storage and transportation.

2. How does the L-Sealer Wire Cable Machine work?

Wire or cable bundles are placed on the infeed platform or conveyor.

Sensors or guides align the bundles for precise sealing.

The L-shaped sealing arm applies heat or pressure to seal the film around the bundle.

Excess film is trimmed automatically, leaving a clean, professional seal.

Sealed bundles exit the machine for storage, shipping, or further processing.

3. What types or variants of L-Sealer machines are available?

Manual L-Sealer: Low-volume operations, operator-controlled.

Semi-Automatic L-Sealer: Operator loads bundles; machine seals automatically.

Fully Automatic L-Sealer: Conveyor-fed, minimal human intervention, high-volume production.

Shrink Film Compatible L-Sealer: For heat-shrinkable packaging around sensitive cables.

4. Which industries use this machine?

Wire and cable manufacturers

Electrical and telecom component suppliers

Industrial and construction cable distributors

Export-oriented packaging units

5. What sizes and materials can it handle?

Bundles of wires and cables with different diameters and lengths

Compatible with polyethylene, shrink films, and laminated packaging films

Suitable for coated, insulated, or bare conductor cables

7. How does automation affect productivity?

Manual wrapping is slow and labor-intensive.

Semi-automatic machines allow operators to load bundles while the machine seals.

Fully automatic machines integrate with conveyor lines, increasing throughput and reducing labor costs.

8. What safety features are included?

Emergency stop buttons at multiple points

Protective guards around moving and heated parts

IEC electrical safety compliance

Lockout-Tagout (LOTO) ready

These features protect operators and reduce workplace accidents.