Leveraging on our widely spread distribution network, we deal in a high performing range of Box Stretch Wrapper which is used for stretch film wrapping around the box or a carton. The offered machine is widely acclaimed in several industries which is capable of packing the product after attaching and wrapping the film. Owing to the features such as low maintenance cost, easy operations and excellent performance, these machines are widely appreciated in this highly competitive market.

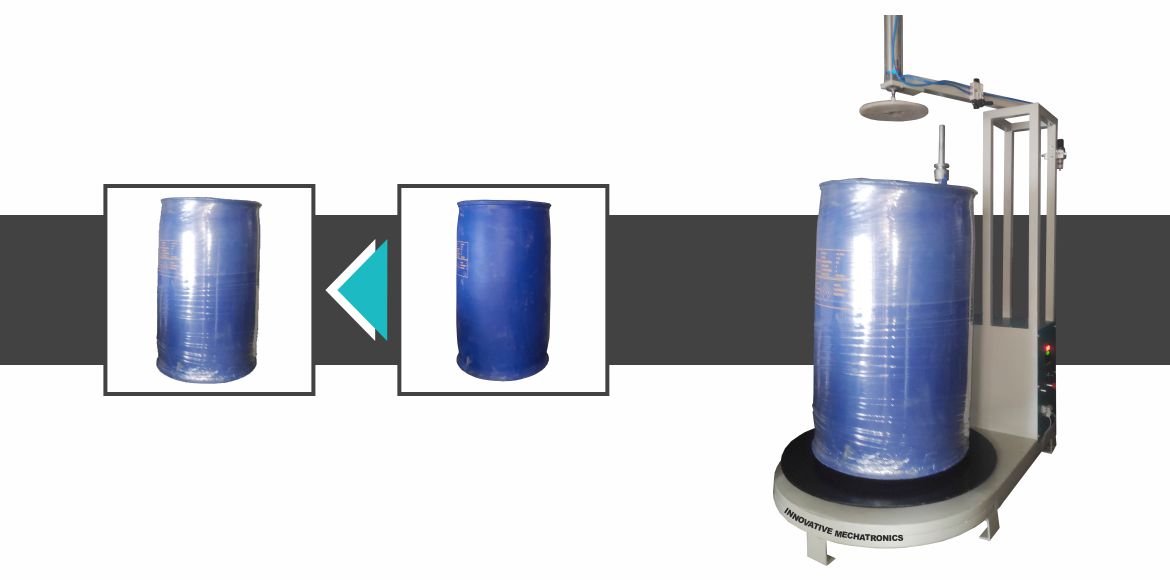

Single Drum Packing Machine

The Single Drum Packing Machine is an industrial equipment designed to pack drums efficiently, securely, and consistently. It ensures that liquid, powder, or granular contents are safely sealed, preventing spillage and contamination. The machine is widely used in chemical, pharmaceutical, food, and industrial sectors, where drum integrity and handling efficiency are critical.

Why This Machine Is Important in Modern Industrial Operations

Prevents Product Loss: Ensures secure sealing to avoid spillage.

Enhances Safety: Reduces operator exposure to hazardous materials.

Increases Efficiency: Packs drums faster and more consistently than manual methods.

Reduces Labor Costs: One operator can handle multiple drums per shift.

Supports High-Volume Operations: Essential for modern factories and warehouses.

How to Choose the Right Machine

When selecting a Single Drum Packing Machine, consider:

Capacity: Match the machine with drum size (typically 50–250 liters) and weight.

Material: Ensure compatibility with the type of contents (liquid, powder, granules).

Automation Level: Semi-automatic for small batches; fully automatic for high-volume lines.

Budget: Balance initial investment with savings in labor, reduced damage, and increased throughput.

Safety Standards, Compliance, and Operator Protection

Designed according to ISO 9001 and CE standards.

Guards and interlocks prevent accidental contact with moving parts.

Emergency stop buttons provide instant shutdown.

Operators should wear gloves, safety shoes, and protective gear when handling hazardous materials.

Reasons Manufacturers Prefer Professional-Grade Machines

Durable and Long-Lasting: Can withstand heavy industrial use.

Reliable Performance: Maintains consistent sealing and packing quality.

Lower Maintenance Costs: High-quality components reduce downtime.

Safer Operation: Advanced safety features protect operators.

Better ROI: Faster throughput, reduced product loss, and labor savings justify the investment.

Frequently Asked Questions (FAQ)

Q1: What are the power and energy requirements of this machine?

The Single Drum Packing Machine operates on 220V single-phase or 380V three-phase power, with energy-efficient motors to minimize consumption.

Q2: Can it handle different drum sizes?

Yes, the machine is adjustable to fit multiple drum sizes for liquids, powders, or granules.

Q3: Is operator training required?

Yes, basic training ensures safe and efficient operation.

Q4: How long is the expected service life?

With proper maintenance, the machine lasts 10–15 years, offering long-term reliability.

Q5: Is this machine suitable for small and medium businesses?

Yes, it is ideal for small, medium, and large-scale industrial operations, providing consistent packing efficiency.

Q6: Does Innovative WrapTech Pvt. Ltd. offer customized machines?

Yes. Innovative WrapTech Pvt. Ltd. manufactures customized Single Drum Packing Machines in the range of ₹3 lakh to ₹10 lakh, based on drum size, material, automation level, and production requirements.