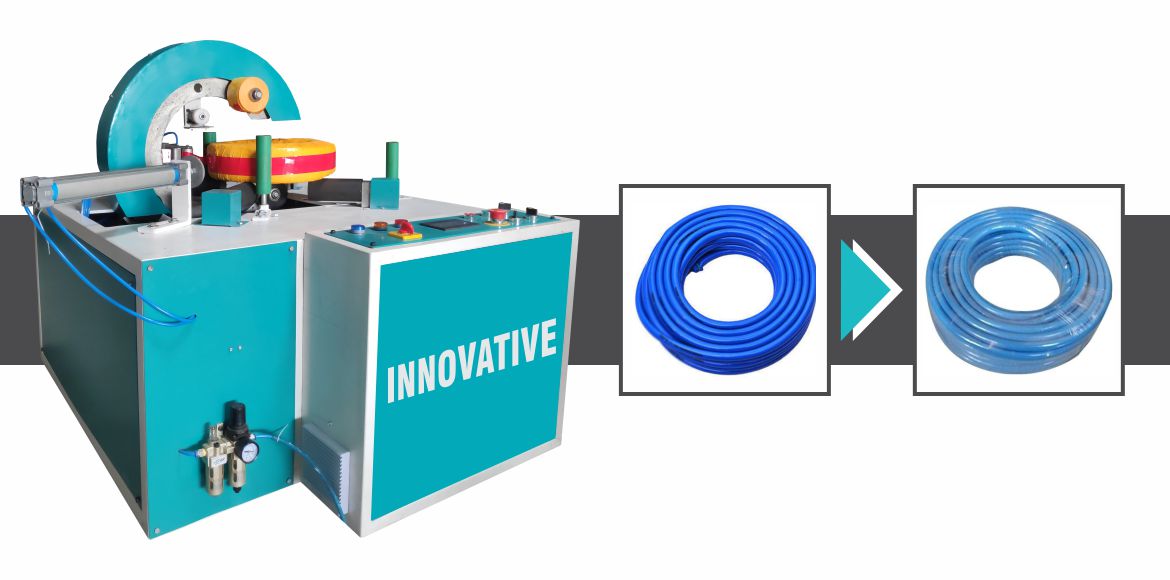

The Hose Pipe Wrapping Machine also called Small Pat Strep Film Wrapping Machine is used for Spiral / Periphery Stretch Wrapping of Coil Shaped Products and Products with Long Lengths.

Pat Strep Coil Wrapping Machine use To wrapping 25 Kg garden pipe wrap also wrap 3Kg to 25 Kg Tyre, ID: 200 To 500 MM, OD: 250 To 700 MM and Width: 30 To 150 MM.

The machine offers various controls for wrapping the stretch film and jute/paper roll at desired wrap tension and for wrapping different wrap configurations. The machine is designed for continuous operation and is rigid & sturdy. The machine is designed with an emphasis of functionality, reliability, and ease of operation.

Coil wrapper wraps the coil-shaped products in a spiral manner through the eye of the product. This is a means of applying a stretch film to a load consisting of stretch rollers supported on a vertical ring. It has a means of passing a load through a ring’s eye horizontally.

Hose Pipe Wrapping Machine

A Hose Pipe Wrapping Machine is an industrial system designed to wrap flexible pipes, hoses, and tubing with protective films such as stretch film, LDPE, or HDPE. The machine secures hoses in coils or bundles, maintaining their shape, preventing tangling, and protecting them from dust, moisture, UV exposure, and mechanical damage during storage, transportation, and handling.

Manufacturers use this machine to ensure consistent packaging quality, improve efficiency, and reduce labor dependency in high-volume hose production lines.

Why Is This Machine Critical in Modern Industrial Operations?

Flexible hoses and tubing are prone to damage, deformation, and contamination if handled manually. Manual wrapping is inconsistent and slows production.

Innovative WrapTech Pvt. Ltd. designed the machine to:

Increase throughput and efficiency

Reduce labor costs and manual handling

Ensure uniform wrapping for all coil sizes

Protect hoses from moisture, dust, and UV exposure

Enhance workplace safety

Modern hose manufacturers depend on automated wrapping for quality assurance and high-volume operations.

Key Technical Features and Operational Benefits

| Feature | Operational Benefit |

|---|---|

| PLC + HMI Control | Easy operation and precise settings |

| Adjustable Film Tension | Prevents deformation of hoses |

| Automatic Film Cut & Clamp | Reduces downtime and labor |

| Sensor-Based Positioning | Ensures consistent wrapping quality |

| Variable Speed Control | Matches production output |

| Conveyor Integration | Minimizes manual handling |

How Buyers Should Choose the Right Machine

Consider these factors before purchasing:

Coil size and weight range (inner diameter, outer diameter, width)

Production speed (coils per hour required)

Material type (stretch film, LDPE, HDPE, VCI)

Automation level (semi-automatic or fully automatic)

Integration with conveyor or production line

Budget and ROI expectations

Choosing the right model ensures maximum efficiency, minimal downtime, and cost savings.

Common Operational Problems and Solutions

Uneven or loose wrapping: Solved with tension-controlled automation

Dust and moisture contamination: Solved with protective film coverage

Labor fatigue: Reduced by fully automated systems

Excessive material waste: Controlled film application minimizes waste

Inconsistent coil presentation: Ensured by sensors and PLC-controlled rotation

Future Trends and Smart Factory Integration

Hose pipe wrapping machines are evolving with:

PLC connectivity to MES or ERP systems

Data-driven maintenance and analytics

Automated material handling and robotic loading

Industry 4.0 smart factory integration for traceability and efficiency

These innovations improve productivity, reduce errors, and support high-volume production lines.

FAQs

1. What is a Hose Pipe Wrapping Machine?

A hose pipe wrapping machine is an industrial system that wraps flexible hoses, tubing, and pipes using stretch film, LDPE, or HDPE. It protects coils from dust, moisture, UV, and mechanical damage while maintaining coil shape.

2. How does a hose pipe wrapping machine work?

The machine positions the hose coil on a conveyor or platform, centers it, and rotates the orbital wrapping ring around the coil. It applies stretch film with controlled tension, overlaps it evenly, cuts the film, and clamps it automatically before discharging the wrapped coil.

3. Why is this machine important for industrial operations?

It ensures consistent, high-quality packaging, reduces labor costs, increases throughput, and protects hoses during storage and transport. Manual wrapping cannot match its speed, accuracy, or uniformity.

4. What types of hose pipe wrapping machines are available?

Semi-Automatic: Best for low to medium production volumes.

Fully Automatic: Ideal for high-speed production and conveyor integration.

Horizontal Orbital: Maintains coil stability and uniform wrapping.

Tapping/Branding System: Adds brand tape or labeling on coils.

5. What are the key technical features?

PLC + HMI control for precise operation

Adjustable film tension to prevent deformation

Automatic film cut and clamp

Sensor-based coil positioning

Variable speed control

Conveyor integration for smooth workflow