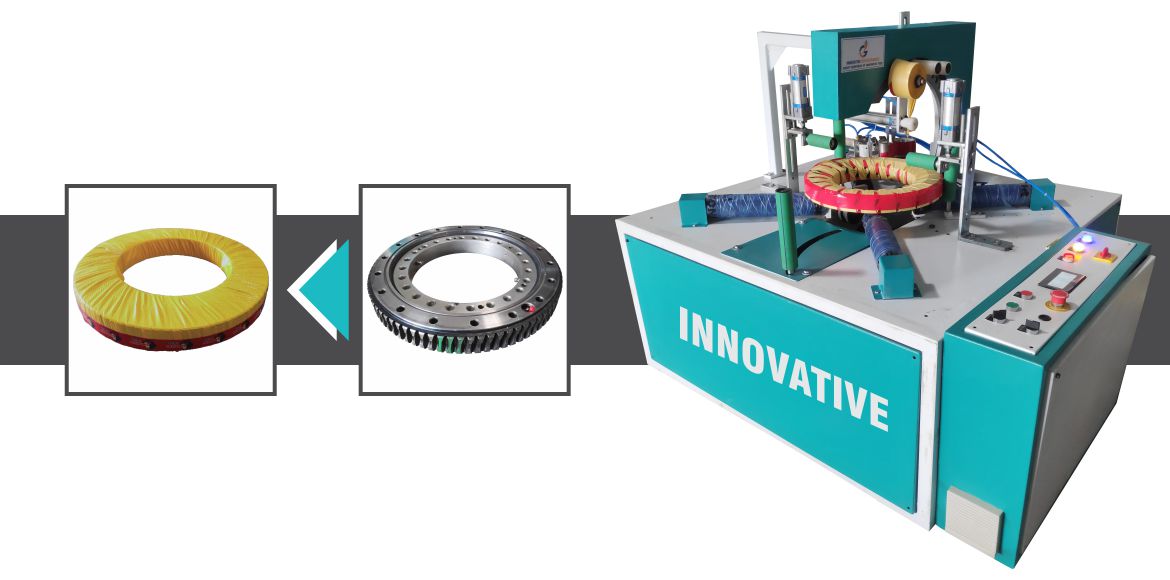

The Brass Coil Stretch Wrapping Machine also called Wire & Cable Film Wrapping Machine is used for Spiral / Periphery Stretch Wrapping of Coil Shaped Products and Products with Long Lengths.

Wire & Cable Film Wrpapping machine use To wrapping 2 Kg To 50 Kg wire bandal Film Wrapping. ID : 150 To 500 MM, OD: 200 To 700 MM and Width : 20 To 100 MM.

The machine offers various controls for wrapping the stretch film and jute/paper roll at desired wrap tension and for wrapping different wrap configurations. The machine is designed for continuous operation and is rigid & sturdy. The machine is designed with an emphasis of functionality, reliability, and ease of operation.

Coil wrapper wraps the coil-shaped products in a spiral manner through the eye of the product. This is a means of applying the stretch film to a load consisting of stretch rollers supported on a vertical ring. It has a means of passing a load through ring’s eye horizontally.

Brass Coil Stretch Wrapping Machine

Brass coil stretch wrapping is an industrial packaging process that applies stretch film tightly around brass coils to protect them from moisture, oxidation, surface scratches, and handling damage. A Brass Coil Stretch Wrapping Machine automates this process by wrapping coils evenly while maintaining controlled film tension and consistent coverage.

Manufacturers use this machine to preserve surface finish, maintain coil integrity, and reduce packaging time in metal processing environments.

How Does a Brass Coil Stretch Wrapping Machine Work?

The operator or conveyor places the brass coil onto the wrapping station.

Sensors detect the coil’s inner diameter, outer diameter, and width.

The machine centers the coil to prevent vibration or movement.

The orbital wrapping ring rotates around the brass coil.

The system stretches and applies the film with controlled tension.

The film overlaps evenly to create a sealed protective layer.

The machine cuts and clamps the film automatically.

The wrapped brass coil exits safely for storage or dispatch.

This controlled process ensures uniform, damage-free, and corrosion-resistant wrapping.

Why Is This Machine Important in Modern Industrial Operations?

Brass coils are sensitive to moisture and surface damage. Manual wrapping often results in:

Uneven film tension

Surface scratches

Excess material usage

High labor dependency

A Brass Coil Stretch Wrapping Machine solves these problems by:

Protecting coils from corrosion and oxidation

Improving packaging speed and consistency

Reducing labor costs and manual handling

Enhancing packaging appearance for exports

Supporting high-volume production environments

Types and Variants of Brass Coil Stretch Wrapping Machines

1. Semi-Automatic Brass Coil Wrapping Machine

Best for: Medium-scale operations

Advantage: Cost-effective and flexible handling

2. Fully Automatic Brass Coil Wrapping Machine

Best for: High-volume production lines

Advantage: Conveyor integration and minimal operator involvement

3. Horizontal Orbital Coil Wrapping Machine

Best for: Heavy and large-diameter brass coils

Advantage: Stable wrapping with uniform tension

4. Rust-Protective Wrapping Configuration

Best for: Export or long-term storage

Advantage: Supports VCI film or moisture barrier materials

How Buyers Should Choose the Right Machine

Buyers should evaluate:

Coil dimensions and maximum weight

Required level of automation

Type of protective film used

Floor space and layout

Budget and expected ROI

Selecting the correct machine ensures long-term reliability and consistent packaging quality.

Asked Questions (FAQs)

Can the machine handle heavy brass coils?

Yes, machines can be customized for coils up to 5 tons or more.

Which film works best for corrosion protection?

VCI stretch film provides excellent corrosion resistance.

Is automation expandable later?

Yes, semi-automatic machines can be upgraded with conveyors and automation modules.