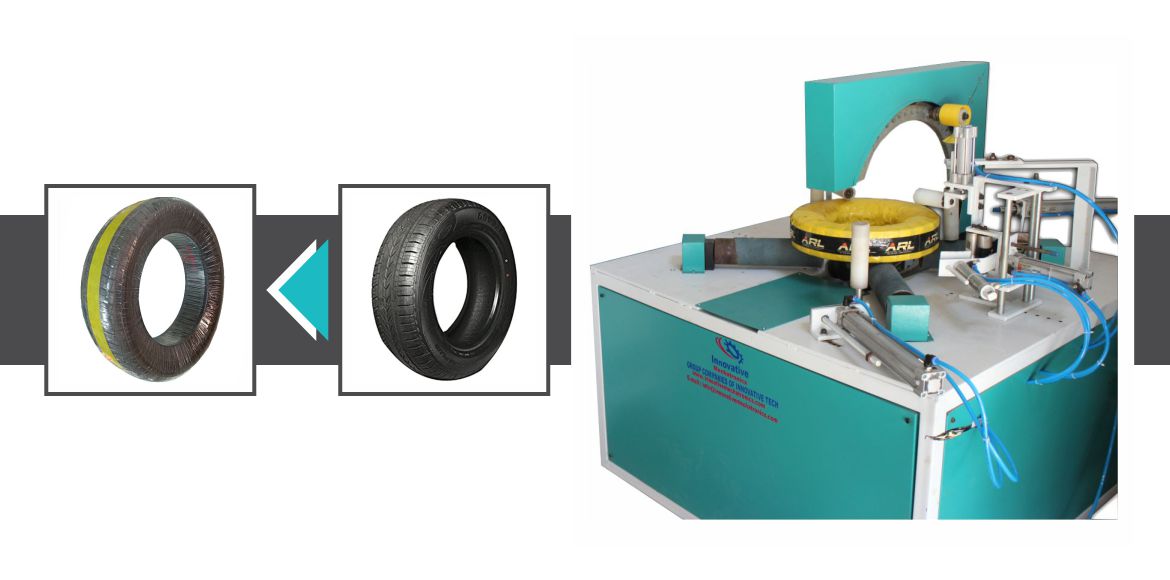

The Tire Packing Machine also called Wire & Cable Film Wrapping Machine is used for Spiral / Periphery Stretch Wrapping of Coil Shaped Products and Products with Long Lengths.

Wire & Cable Film Wrpapping machine use To wrapping 2 Kg To 50 Kg wire bandal Film Wrapping. ID : 150 To 500 MM, OD: 200 To 700 MM and Width : 20 To 100 MM.

The machine offers various controls for wrapping the stretch film and jute/paper roll at desired wrap tension and for wrapping different wrap configurations. The machine is designed for continuous operation and is rigid & sturdy. The machine is designed with an emphasis of functionality, reliability, and ease of operation.

Coil wrapper wraps the coil-shaped products in a spiral manner through the eye of the product. This is a means of applying the stretch film to a load consisting of stretch rollers supported on a vertical ring. It has a means of passing a load through ring’s eye horizontally.

Tire Packing Machine

When self weight of product coil is less than 25kg, Inner diameter is 200mm to 500mm, Outer diameter is 300mm to 700mm, width is 50mm to 150mm then we prefer Tire Packing Machine

Tapping System type Machine:-

There is one other type of tyre coil wrapping machine also existing which is called Tapping system.

In this we can put tap on the outer surface of coil for your company branding.

About tire coil packing machine:-

First of all, suppose your production rate is very high and your product is coming from conveyor in that case with the use of automatic horizontal tyre coil wrapping machine product handling is getting very easy.

Secondly, Your product weight is too high but your product width is too small in that situation you can also go with automatic bike tyre coil wrapping machine with conveyor.

How to use car Tyre Coil wrapping Machine:-

1.) First of all put product in machine.

2.) Then press START button.

3.)Automatic wrapping & tapping will be start just after starting machine.

4.)The machine will be stop on which count you had set.

5.)Lastly Start ejector after starting that product will come outside.

Advantages Of three Wheler tyre stretch wrap machine:-

1.) Protection from entry of Dust, Moisture, Foreign Particles

2.) Protection from Tamper

3.)Uniform/ Consistent Packing

4.) Saves Packaging Labour cost and Time

5.) Globally favoured form of Packaging.

features Of tire stretch Packing machine:-

1.) Adjustable Film Overlap

2.)PLC Based Operations

3.) Automatic cutting and holding of film.

4.)Adjustable stretch ratio.

5.) Vibration free Operation

6.) Logo PLC base operation for timing of wrapping

7.) Rotation, Cutting, ejection

8.) Advance paper relish system.

Frequently Asked Questions (FAQs)

Q1. What is a Tire Packing Machine?

A Tire Packing Machine is used to wrap and pack tires with stretch film or protective material to protect them from dust, moisture, and handling damage during storage and transportation.

Q2. What types of tires can this machine pack?

The machine can pack passenger car tires, truck tires, tractor tires, and other industrial tires, depending on the machine model and configuration.

Q3. Which industries use a tire packing machine?

Industries such as tire manufacturing, automotive, rubber processing, and logistics commonly use tire packing machines.

Q4. Does the machine support different tire sizes?

Yes. The machine supports multiple tire diameters and widths through adjustable settings and configurations.

Q5. Does the machine reduce manual labor and packing time?

Yes. Automated packing improves efficiency, reduces manual labor, and ensures consistent tire protection.