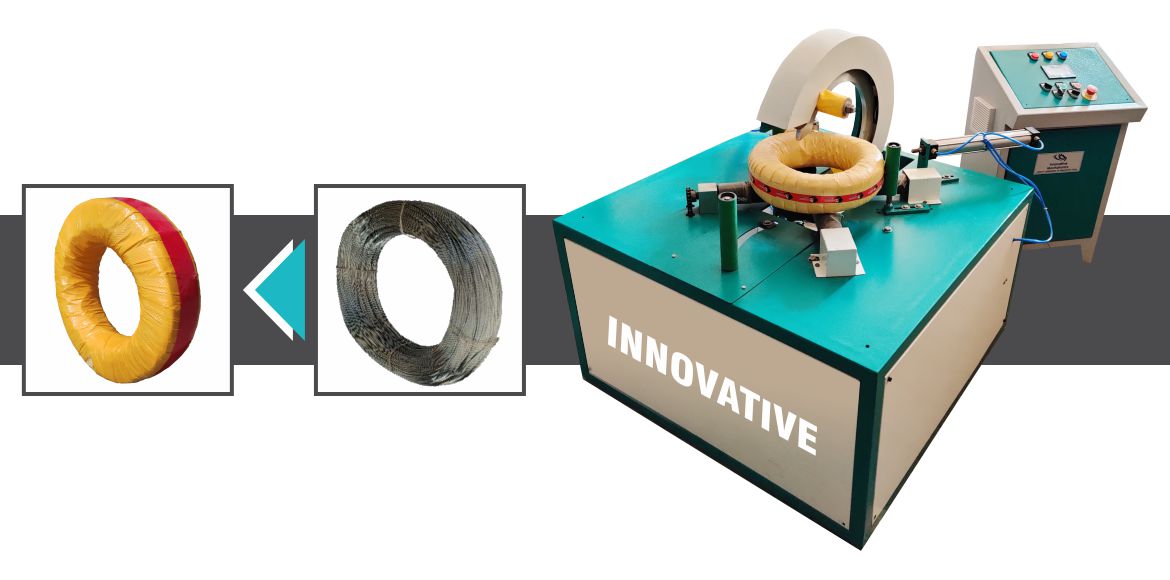

The Binding Wire Packing Machine also called Wire & Cable Film Wrapping Machine is used for Spiral / Periphery Stretch Wrapping of Coil Shaped Products and Products with Long Lengths.

Wire & Cable Film Wrpapping machine use To wrapping 2 Kg To 50 Kg wire bandal Film Wrapping. ID : 150 To 500 MM, OD: 200 To 700 MM and Width : 20 To 100 MM.

The machine offers various controls for wrapping the stretch film and jute/paper roll at desired wrap tension and for wrapping different wrap configurations. The machine is designed for continuous operation and is rigid & sturdy. The machine is designed with an emphasis of functionality, reliability, and ease of operation.

Coil wrapper wraps the coil-shaped products in a spiral manner through the eye of the product. This is a means of applying the stretch film to a load consisting of stretch rollers supported on a vertical ring. It has a means of passing a load through ring’s eye horizontally.

Binding Wire Packing Machine

A Binding Wire Packing Machine is an industrial system that wraps and secures steel or iron binding wire coils using stretch film, HDPE, or LDPE packaging. The machine ensures that each coil maintains its shape, stays protected from dust, moisture, and mechanical damage, and is ready for storage or dispatch.

Manufacturers rely on this machine to maintain consistent packaging quality, improve handling safety, and increase production efficiency.

How Does a Binding Wire Packing Machine Work? (Step-by-Step)

The operator places a binding wire coil onto the machine platform or conveyor.

Sensors detect the coil’s dimensions and position.

The machine centers the coil automatically for uniform wrapping.

The rotating orbital arm or wrapping ring begins applying the film around the coil.

The machine controls film tension to prevent coil deformation or damage.

The film overlaps uniformly across the coil for full coverage.

The system cuts and clamps the film automatically after wrapping.

The machine discharges the wrapped coil for stacking or shipment.

This automated process ensures repeatable, high-quality, and safe packaging.

Why Is This Machine Important in Modern Industrial Operations?

Binding wire is a high-volume product used in construction, fencing, and industrial applications. Packaging coils manually is:

Labor-intensive

Inconsistent

Time-consuming

Risky for worker safety

The Binding Wire Packing Machine addresses all these challenges. It improves throughput, protects coils, reduces labor costs, and ensures uniformity for large-scale industrial operations.

Types and Variants of Binding Wire Packing Machines

1. Semi-Automatic Binding Wire Packing Machine

Use: Low to medium production volumes

Advantage: Lower investment, flexible operation

2. Fully Automatic Binding Wire Packing Machine

Use: High-speed production lines

Advantage: Minimal manual handling, consistent output

3. Orbital Horizontal Wrapping Machine

Advantage: Uniform tension, full surface coverage

4. Tapping System Packing Machine

Use: Branding or labeling coils

Advantage: Outer surface tape or logo application for brand recognition

Key Technical Features and Operational Benefits

| Feature | Operational Benefit |

|---|---|

| PLC + HMI control | Precise, repeatable control and easy operation |

| Adjustable film tension | Prevents coil deformation and maintains shape |

| Automatic film cutting & clamping | Reduces downtime and labor |

| Sensor-based positioning | Ensures accurate, uniform wrapping |

| Variable speed control | Matches production line output |

| Conveyor integration | Minimizes manual handling |

Common Operational Problems This Machine Solves

Coil contamination from dust or moisture

Labor-intensive and slow manual packaging

Excessive material waste

Safety risks from manual handling

The machine resolves these issues through automated, tension-controlled, and repeatable wrapping.

Frequently Asked Questions (FAQs)

Q1. What is a Binding Wire Packing Machine?

A Binding Wire Packing Machine is used to wrap and pack binding wire coils with stretch film or protective material to prevent rust, dust, and damage during storage and transportation.

Q2. What types of binding wire can this machine pack?

The machine can pack mild steel binding wire, galvanized wire, and other industrial wire coils, depending on the machine model and configuration.

Q3. Which industries use a binding wire packing machine?

Industries such as construction, wire manufacturing, metal processing, and logistics commonly use binding wire packing machines.

Q4. Does the machine support different coil sizes?

Yes. The machine supports multiple binding wire coil diameters and widths through adjustable settings.

Q5. Does the machine reduce manual packing effort?

Yes. Automated packing improves efficiency, reduces manual labor, and ensures consistent coil protection.