Innovative Mechatronics makes the best manual Pallet wrapping machine. which is a very low price pallet wrapping machine.

It gives various types of advantages to the user and includes many features in it.

Product damage, labor, and material costs have the most significant impact when it comes to Manual pallet wrapping. Most people typically look at the machine price tag when considering a new machine. When in fact – the price has the least impact. Although a pallet wrapper can reduce the extra expenditure from those three main cost drivers that might cost more upfront, it can pay itself off in a relatively short period through the savings it provides.

- save film Upto 300 % with a Pre-stretch unit system

- save labor

- uniform packaging, however, Film Tension Control Adjustment

- Advanced Photo Eye to Sense on the Package Angle.

- High-Quality

Manual Pallet Wrapping Machine

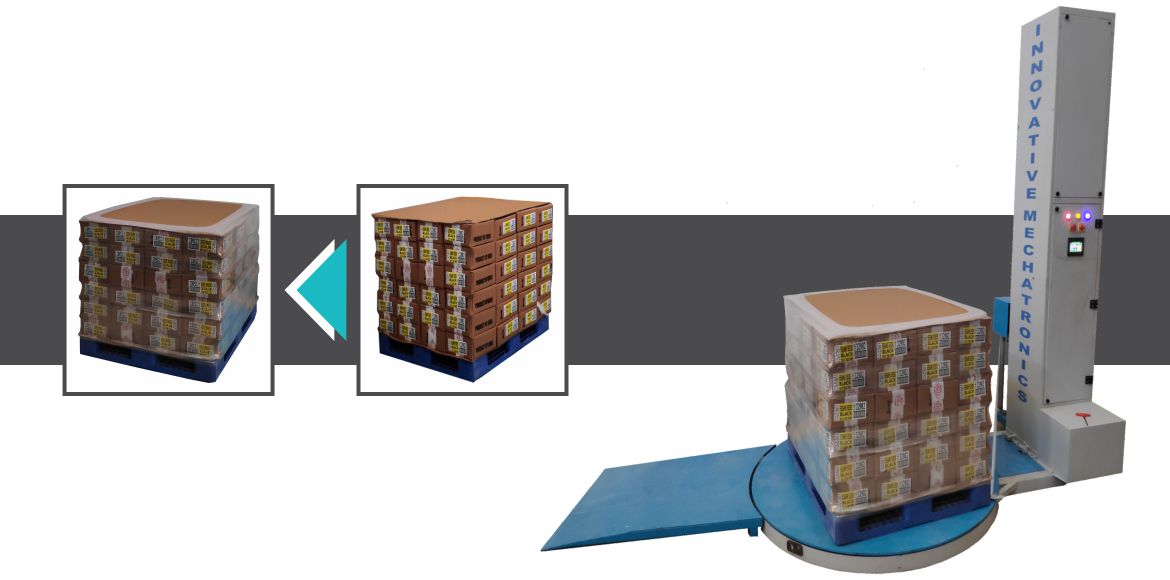

A Manual Pallet Wrapping Machine is a cost-effective, operator-driven pallet wrapping system designed to secure boxes, cartons, drums, or other palletized goods using stretch film. Unlike automatic systems, this machine requires the operator to manually move the film carriage around the pallet or rotate the turntable to wrap the load.

It is ideal for small-to-medium production volumes where flexibility, low investment, and simple operation are priorities.

Why This Machine Is Important in Modern Industrial Operations

Modern warehouses and production facilities need consistent load stability, product protection, and safe transport, even at smaller scales.

Key benefits of a Manual Pallet Wrapping Machine:

Ensures pallet load stability during storage and transport

Protects goods from dust, moisture, and accidental damage

Reduces labor strain compared to fully manual wrapping

Increases operational efficiency for small-scale operations

Offers affordable entry to professional-grade pallet wrapping

Manual pallet wrappers bridge the gap between manual packaging and high-end automated systems.

How to Choose the Right Manual Pallet Wrapping Machine

1. Load Capacity

Choose a machine suitable for the maximum pallet weight you handle.

Standard manual models handle up to 1,000–2,000 kg per pallet.

2. Material and Product Type

Works with cartons, boxes, drums, and bags.

Select models with adjustable film tension to protect delicate items.

3. Operator and Automation Level

Requires minimal operator training.

Ideal for semi-manual operations where one operator manages the wrapping.

4. Budget and ROI

Manual machines have lower initial investment.

Offer quick returns by reducing product damage and labor inefficiencies.

Safety Standards, Compliance, and Operator Protection

Innovative WrapTech Pvt. Ltd. designs all manual pallet wrappers with operator safety in mind.

Key Safety Features

Stable turntable design to prevent tipping

Smooth film carriage movement to avoid strain or injury

Electrical safety compliance for powered features

Compliance Standards

CE-certified components

ISO-quality manufacturing

IEC-compliant electrical systems

These measures ensure safe and reliable operation in industrial environments.

Why Manufacturers Prefer Professional-Grade Manual Machines

Professional manual pallet wrappers outperform low-quality alternatives in durability and consistency.

Key Advantages

Long-lasting, heavy-duty construction

Consistent film tension and load protection

Minimal maintenance requirements

Easy integration with existing warehouse operations

Ergonomic design for operator safety

Manufacturers rely on professional models for efficient, repeatable, and safe pallet wrapping.

Frequently Asked Questions (FAQ)

1. What are the energy and power requirements?

Manual models typically have minimal electrical consumption for powered turntables or film carriages, ranging from 0.5–1 kW.

2. Can the machine wrap different pallet sizes?

Yes. Adjustable guides and tension settings support multiple pallet dimensions.

3. Is training required for operators?

Basic training ensures optimal wrapping quality and safe operation.

4. Does it reduce film wastage?

Yes. Professional tension controls minimize unnecessary film usage.

5. Can it handle high-throughput operations?

Manual pallet wrappers are best for small-to-medium volumes; for continuous high-speed production, semi-automatic or automatic machines are recommended.

Conclusion

A Manual Pallet Wrapping Machine from Innovative WrapTech Pvt. Ltd. provides affordable, safe, and reliable pallet wrapping for small to medium-scale industrial operations. It improves load stability, protects products, and enhances operational efficiency while requiring minimal investment and maintenance.