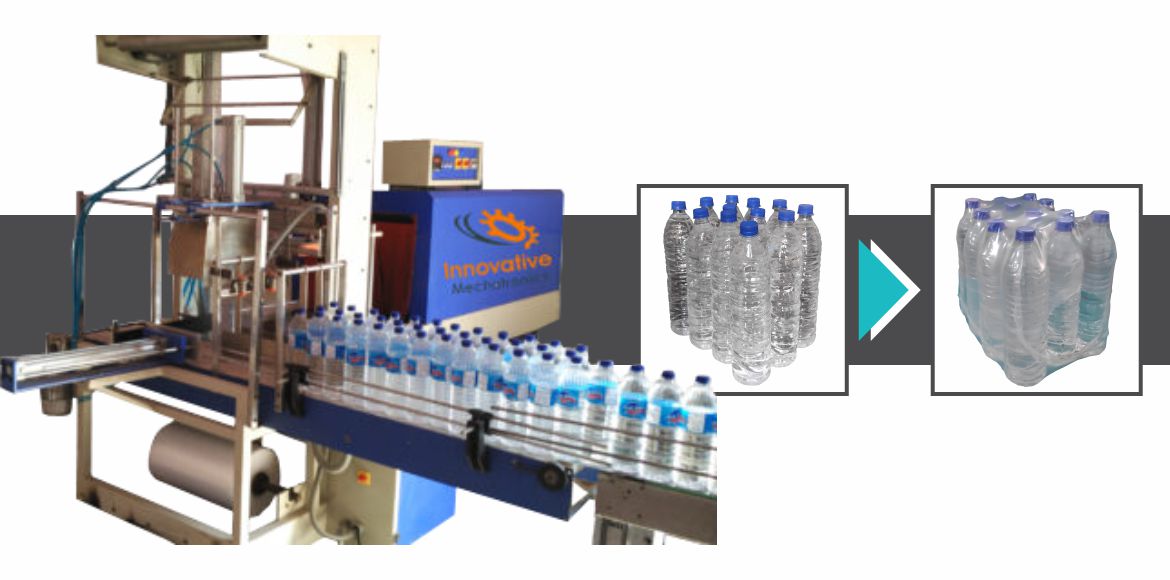

The fully automatic shrink-wrap machine is such a machine using such a shrink-wrapping machine the products can be collected and can make a proper matrix for the products manufactured in Pharma, non-pharma such as food and FMCG companies.

The Fully automatic shrink wrapping machines are more applicable and are suitable for the high-speed production filling and packing lines to complete the packing activities in a short period.

The high-speed filling and packing production lines can be seen in the following companies and product lines:

- Fully automatic Shrink wrapping machine for pharma companies product line

- fully automatic Shrink wrap machine for syrup filling and packing lines

- fully automatic Shrink wrap machine for tablet blisters packing line

- Fully Automatic Shrink Wrapping Machine for FMCG and Food manufacturing companies

- fully automatic Shrink Wrap machine for food packing lines line juice, souse, soup, etc

fully automatic Shrink wrap machine is more useful for cold drinks, cola and mineral water packing lines and is more cost-effective advantageous over shipper carton packing and also advantageous over packing timing

Automatic Shrink Wrap Machine

Bottle Automatic Shrink Wrapping semi-automatic shrink wrapper also called bottle

The fully automatic shrink-wrap machine is such a machine using such a shrink-wrapper the products can be collected and can make a proper matrix for the products manufactured in Pharma, non-pharma such as food and FMCG companies.

About shrink wrapping machine for bottles

The high-speed filling and packing production lines can be seen in the following companies and product lines:

Automatic Shrink Wrapping Machine delivered by leading manufacturer & exporter, innovative finds utility in some of the crucial packaging projects.

More detail for shrink wrapper

Depending upon the feeding requirements, this shrinking machine will offer an output of packing 3 to 4 packs per minute, where the packet measurements are 450mm in length 300mm in width and 350mm in height.

Other than that, the Bottle bottle shrink packing is perfect for packing bottled items without cork such as glass bottles; pop can, mineral water, and several beverages.

Use of semi automatic shrink wrapping machine

The automatic water bottle packing machine are highly useful for packing and preserving food items such as fruits, stationery, medical drugs, salty foods, cosmetics, hardware parts, books, and boxes.

Additionally, this shrinking equipment is highly useful and applicable for PVC and PE shrink film. It mainly consists of three sections and is capable of wrapping bottles of 200 ml to 2 liters.

How Does an Automatic Shrink Wrap Machine Reduce Waste and Improve Resource Efficiency?

An Automatic Shrink Wrap Machine reduces waste by using precise film control and automated sealing systems that apply only the required amount of shrink film to each product. The machine maintains consistent film tension and accurate heat distribution, which prevents over-wrapping, film tearing, and rework. This controlled process significantly lowers shrink film consumption compared to manual or semi-automatic methods.

The machine also minimizes product rejection by producing uniform, tightly sealed packs every cycle. Consistent packaging reduces damage during handling and transportation, which saves material, labor, and energy costs. High-speed automation further improves efficiency by reducing manual intervention, lowering labor dependency, and increasing output per hour.

Energy-efficient heat tunnels and optimized heating zones reduce power consumption while maintaining effective shrinking performance. Over time, these efficiencies translate into lower operating costs, reduced material waste, and improved sustainability for industrial packaging operations.

automatic water bottle packing machine Innovative Mechatronics Quality:

*An ISO and CE certified company.

*Expert manufacturer with more than 10 years’ experience in the coil packing field.

*Provided reliable and high-quality coil wrap machine.

*Providing custom-built hose packing machines according to special requirements.

*Provid update and on-time technical support.

*Long-term, reliable and easy operation bottle shrink packing .