From Dumb to Smart: How AI and Data Analytics are Transforming Packaging Production

AI Powered Packaging Production: How Data Analytics Drive Smarter Manufacturing

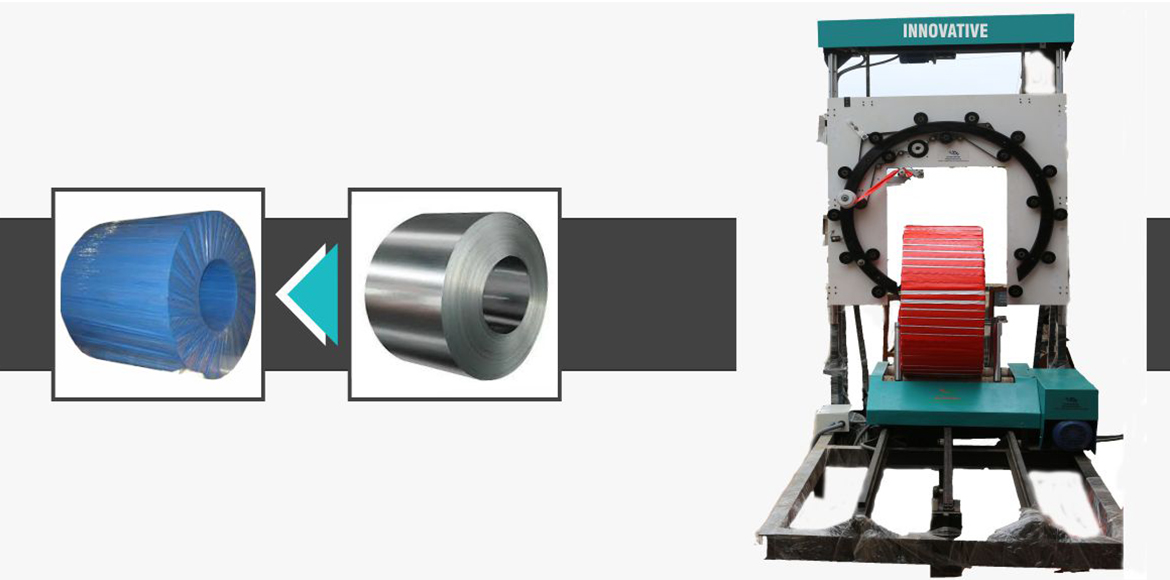

What the Product Is

Smart packaging machines powered by AI and data analytics represent the next generation of industrial automation. Unlike traditional “dumb” machines that operate on fixed settings, AI-enabled packaging systems continuously collect, analyze, and optimize data in real time.

These systems integrate:

Intelligent sensors

Machine vision

Predictive algorithms

At Innovative WrapTech Pvt. Ltd., smart packaging solutions use AI to automatically adjust wrapping tension, speed, film usage, and load stability based on live production data—delivering consistent output with minimal human intervention.

Why This Machine Is Critical in Modern Industrial Operations

In today’s high-volume, cost-sensitive manufacturing environment, efficiency and accuracy directly impact profitability. AI-driven packaging machines have become essential because they:

Eliminate human guesswork by using data-backed decisions

Reduce material waste through precise film optimization

Improve product safety via real-time load monitoring

Support Industry 4.0 and smart factory integration

Modern industries no longer compete on production speed alone—they compete on data intelligence, and smart packaging machines deliver that advantage.

How to Choose the Right Smart Packaging Machine

1. Capacity Requirements

Select a machine that matches your daily and peak production volumes.

Low to medium output → Semi-automatic smart systems

High-speed operations → Fully automatic AI-enabled lines

Oversized machines increase costs, while undersized machines create bottlenecks.

2. Packaging Material Compatibility

Ensure the machine supports:

Stretch film

Shrink film

Specialty films for fragile or heavy loads

AI systems perform best when calibrated for material-specific performance data.

3. Level of Automation

Automation should align with operational maturity:

Assisted automation → Manual loading with smart controls

Full automation → Conveyor integration, robotic pallet handling, ERP connectivity

Innovative WrapTech Pvt. Ltd. designs scalable solutions that grow with your business.

4. Budget and ROI

Smart machines require higher upfront investment but deliver:

Lower long-term operating costs

Reduced labor dependency

Faster ROI through waste reduction and uptime gains

Always evaluate total cost of ownership, not just purchase price.

Safety Standards, Compliance, and Operator Protection

AI-powered packaging machines enhance safety while meeting global compliance standards such as CE, ISO, and OSHA guidelines.

Key safety features include:

Emergency stop systems

Automated fault detection

Load imbalance alerts

Electrical overload protection

Smart systems reduce operator exposure to repetitive strain, heat zones, and unstable loads—creating a safer, more compliant workplace.

Why Manufacturers Prefer Professional-Grade Machines

Manufacturers consistently choose professional-grade AI packaging machines because they:

Deliver industrial durability for 24/7 operations

Maintain consistent quality across shifts

Support predictive maintenance instead of reactive repairs

Integrate easily with existing production software

Enhance brand reputation through professional packaging finish

Innovative WrapTech Pvt. Ltd. focuses on engineering-grade reliability, not consumer-level automation.

The future of packaging is smart, connected, and data-driven.

AI and analytics transform packaging machines from simple tools into strategic production assets.

With Innovative WrapTech Pvt. Ltd., manufacturers move from dumb machines to intelligent systems that deliver efficiency, safety, sustainability, and measurable ROI.

Frequently Asked Questions (FAQs)

1. What makes AI-based packaging machines smarter than traditional systems?

AI machines analyze real-time data to self-adjust performance, while traditional machines rely on fixed, manual settings.

2. Do smart packaging machines really reduce material waste?

Yes. AI optimization can reduce film consumption by up to 30–40% through precise tension control and load profiling.

3. Are AI packaging machines difficult for operators to use?

No. Modern interfaces are user-friendly, touchscreen-based, and require minimal training while offering advanced automation in the background.

4. Which industries benefit most from smart packaging technology?

Industries such as FMCG, pharmaceuticals, logistics, automotive, food & beverage, and e-commerce benefit the most from AI-driven packaging.

5. Is AI packaging suitable for small and mid-sized manufacturers?

Absolutely. Modular smart systems allow smaller manufacturers to adopt AI gradually without high upfront complexity.