Automatic Pallet Stretch Wrapping Machine – Save 60% Labor Cost | Manufacturer India

High-Speed Automatic Pallet Stretch Wrapper – Cost-Saving Packaging Machine

What Is an Automatic Pallet Stretch Wrapper?

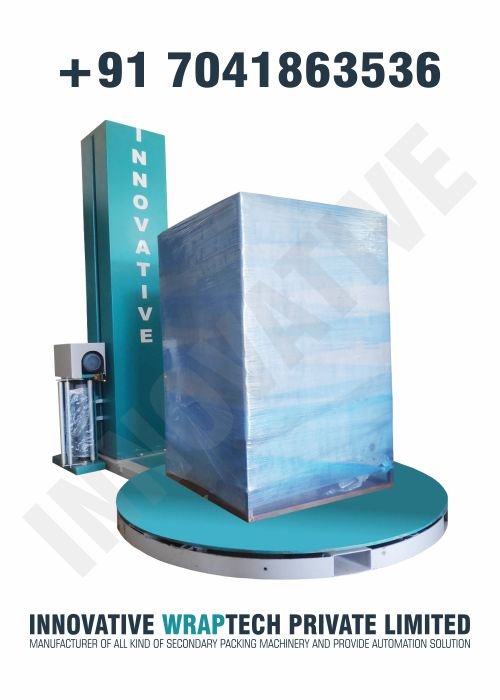

An Automatic Pallet Stretch Wrapper is an end-of-line industrial packaging machine that wraps palletized products with stretch film to stabilize the load during storage, handling, and transportation.

In real factory conditions, pallets often fail due to vibration, tilting, fork-truck shock, or humidity exposure — not because of weak cartons, but because of poor load containment.

This machine solves that problem by applying controlled film tension, uniform overlap, and repeatable wrapping cycles.

Result:

No inconsistent packing

No transit damage claims

Industries using it daily:

FMCG & Food processing

Pharma & chemicals

Tiles, cement & building materials

Logistics warehouses

Automotive components

Export packaging units

Pan-India & Global Supply Coverage

Innovative WrapTech Pvt. Ltd. manufactures and supplies Automatic Pallet Stretch Wrappers across the entire Indian industrial network — from metro cities to remote manufacturing clusters — through a centralized dispatch and coordinated service system.

We regularly deliver machines to Delhi, Noida, Greater Noida, Ghaziabad, Faridabad, Gurugram, Chandigarh, Ludhiana, Amritsar, Jaipur, Bhiwadi, Neemrana, Lucknow, Kanpur, Haridwar, Dehradun, Ahmedabad, Sanand, Vadodara, Bharuch, Ankleshwar, Vapi, Surat, Rajkot, Jamnagar, Morbi, Mumbai, Navi Mumbai, Thane, Pune, Nashik, Aurangabad, Kolhapur, Nagpur, Indore, Pithampur, Bengaluru, Hosur, Chennai, Sriperumbudur, Coimbatore, Tiruppur, Hyderabad, Secunderabad, Visakhapatnam, Vijayawada, Kochi, Trivandrum, Mysuru, Kolkata, Howrah, Durgapur, Jamshedpur, Ranchi, Bhubaneswar, Cuttack, Raipur, Bilaspur, Bhopal and Gwalior, along with surrounding industrial areas and upcoming manufacturing zones.

Instead of treating each city separately, our logistics model works through regional industrial corridors. Machines are pre-tested at the factory, packed in transport-safe condition, and dispatched through trusted freight partners. On arrival, customers receive installation guidance, operating training, and lifetime technical assistance — either onsite or remote depending on project scale.

This unified supply approach allows factories in any location to receive the same engineering-grade machine performance and service reliability as major metro plants. Even smaller towns benefit from remote diagnostics support, fast spare-parts courier dispatch, and video-assisted troubleshooting, ensuring production lines never stop due to packaging downtime.

International Export Supply

Innovative WrapTech Pvt. Ltd. exports Automatic Pallet Stretch Wrappers to major global industrial markets including UAE, Saudi Arabia, Oman, Qatar, Kuwait, Bangladesh, Nepal, Sri Lanka, Vietnam, Thailand, Indonesia, Malaysia, Kenya, Tanzania, Nigeria, Egypt, South Africa, Ethiopia, Germany, Poland, Italy, Spain, Netherlands, USA, Mexico, Brazil, Chile, Peru, Australia, and New Zealand.

We design every export machine according to international industrial standards and country-specific electrical requirements. Our engineering team configures voltage compatibility (220V / 380V / 415V / 440V), frequency settings, and control panel specifications based on the destination country. This ensures seamless installation without additional electrical modification at the buyer’s facility.

Each machine undergoes full pre-dispatch inspection, performance testing, and secure export-grade wooden packaging. We provide complete commercial documentation including invoice, packing list, HS code details, and compliance paperwork required for smooth customs clearance.

To eliminate technical barriers, we offer remote commissioning support, video-based installation guidance, operator training, and digital troubleshooting assistance. This structured export approach allows overseas factories to integrate our pallet wrapping systems into their production lines quickly, safely, and efficiently — minimizing downtime and maximizing operational productivity from day one.

Types of Automatic Pallet Stretch Wrappers

| Type | Used When | Advantages |

|---|---|---|

| Turntable Automatic | Standard pallets, stable loads | Most economical & popular |

| Rotary Arm Wrapper | Heavy or unstable loads | Pallet does not rotate |

| Rotary Ring Wrapper | High speed production lines | 60+ pallets/hour |

| Conveyorized Inline Wrapper | Fully automated factories | No manpower required |

| Mobile Robot Wrapper | Large products / oversized pallets | Flexible movement |

| Top Sheet Wrapper | Export / rain protection | Dust & moisture proof packing |

How the Machine Works

1. Pallet Detection

Operator places pallet on turntable or conveyor

Sensors detect height & load presence

2. Film Attachment

Film clamps automatically or operator hooks film tail

3. Pre-Stretch Activation

Motorized rollers stretch film up to 200–300%

(1 meter film becomes 3 meters coverage)

4. Bottom Wrapping

Turntable rotates

Film applies extra layers at base for load locking

5. Upward Wrapping

Carriage moves vertically

Film overlaps 30–60% for stability

6. Top Reinforcement

Additional wraps applied at top edge

Prevents carton collapse & shifting

7. Downward Locking

Machine wraps downward again

Creates cross-binding effect

8. Film Cutting & Sealing

Hot wire / automatic cutter cuts film

Tail wipes to pallet

9. Pallet Ready

Forklift removes secured load

Cycle Time: 45–90 seconds per pallet

Why This Machine Is Critical in Modern Industry

Manual wrapping problems observed in factories:

Uneven film tension

Operator fatigue

High film wastage

Transit damage complaints

Worker injuries

Automatic wrapper solves all:

Operational Impact

60% labor reduction

30–50% film saving

Zero wrapping inconsistency

Faster dispatch

Improved warehouse safety

Business Impact

Reduced returns

Export compliance

Professional packaging appearance

Why Professionals Avoid Low-Cost Machines

Cheap machines usually have:

Non-motorized stretch

Weak structure vibration

Inconsistent tension

High maintenance downtime

Professional-grade machines provide:

Repeatable wrapping quality

Reliable motors & PLC

Spare availability

Long life (8–12 years)

Future Trends & Smart Factory Integration

Modern factories are moving toward Industry 4.0.

Upcoming integrations:

PLC communication with ERP

Production data tracking

Remote fault diagnosis

Load weight sensing

Automatic film consumption reports

Fully unmanned packaging lines

Automatic pallet wrapping is becoming part of intelligent dispatch systems rather than a standalone machine.

Summary

If your factory operates in any Indian city — metro, industrial cluster, or developing manufacturing zone — Innovative WrapTech Pvt. Ltd. provides:

✔ Direct factory supply

✔ Pan-India installation support

✔ Export-ready systems

✔ Engineering consultation

✔ Long-term service assurance

We support industries locally and globally with the same engineering commitment and industrial reliability standards.

Frequently Asked Questions (FAQ)

1. What types of products can an Automatic Pallet Stretch Wrapper pack?

It can wrap cartons, bags, drums, bottles, tiles, chemicals, food products, and any palletized load requiring stability during storage or transportation.

2. How much stretch film can the machine save compared to manual wrapping?

With motorized pre-stretch rollers, the machine typically reduces film consumption by 30–50% while improving load holding strength.

3. Is the machine suitable for export packaging?

Yes. The wrapper provides uniform tension and multi-layer wrapping, making pallets secure for long-distance and international shipping conditions.

4. Does the machine require skilled operators?

No. Basic training is sufficient. The PLC-based interface allows operators to select programs and run automatic cycles easily.

5. What maintenance is required for long-term operation?

Daily cleaning, weekly lubrication, and periodic inspection of rollers, sensors, and electrical connections ensure reliable performance for many years.