The Automated Revolution: How Carton Stretch Wrapping is Transforming Packaging Efficiency

The Automated Revolution: How Carton Stretch Wrapping Is Transforming Packaging Efficiency

Why Carton Stretch Wrapping Efficiency Matters Today

Modern factories operate under constant pressure to reduce costs, improve throughput, and meet sustainability goals—without compromising load safety. Carton stretch wrapping machines solve this challenge by automating the process of securing cartons, boxes, and bundled products using stretch film.

From FMCG to e-commerce fulfillment centers, manufacturers now rely on automated carton wrapping to eliminate manual inconsistencies, reduce packaging waste, and achieve predictable packaging performance at scale.

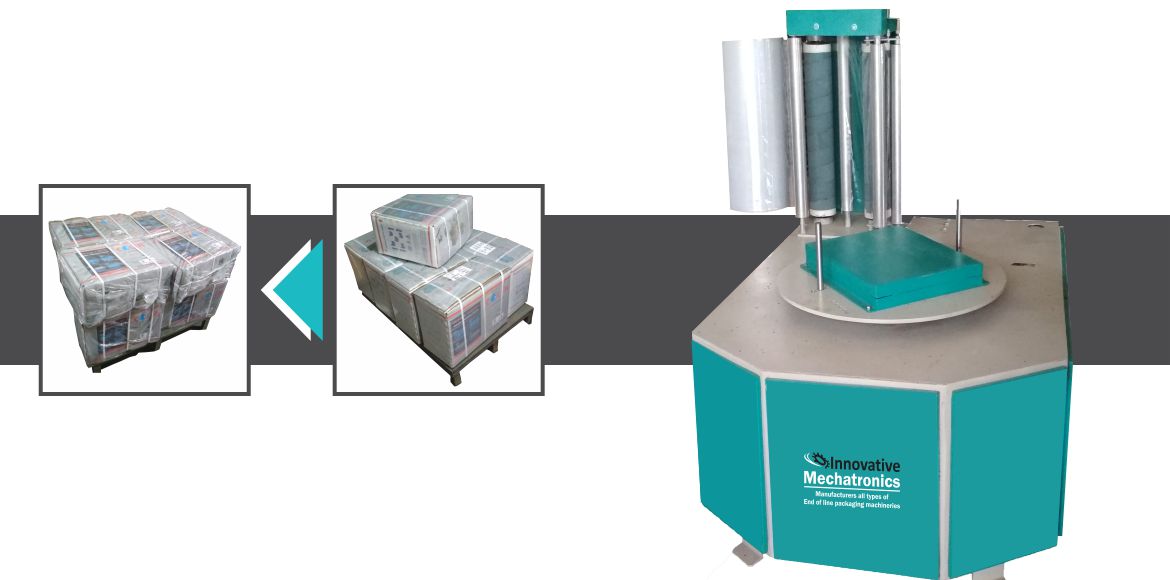

What Is a Carton Stretch Wrapping Machine?

A carton stretch wrapping machine is an automated or semi-automated system designed to tightly wrap cartons or box stacks with stretch film. Unlike pallet wrappers, these machines focus on individual cartons or grouped cartons, ensuring tamper resistance, load stability, and surface protection.

Innovative WrapTech Pvt. Ltd. designs these machines for continuous industrial duty, integrating precision film control, adjustable tension, and optional conveyor automation.

How the Machine Works: Step-by-Step Technical Operation

Carton Infeed

Conveyors or manual loading position the carton into the wrapping zone.Product Detection

Photo sensors detect carton dimensions to auto-adjust film overlap and wrap height.Film Pre-Stretch Activation

The pre-stretch carriage elongates film (typically 200–300%) to reduce material usage.Wrapping Cycle Execution

Rotary ring, orbital arm, or turntable applies film uniformly

Controlled tension prevents carton deformation

Film Cut & Seal

Automatic cutting and film wiping secure the wrap without manual intervention.Discharge & Data Logging

Wrapped cartons exit to downstream conveyors while the system logs cycle data for performance tracking.

Carton Stretch Wrapping – Pan India Manufacturing & City-Based Supply

Innovative WrapTech Pvt. Ltd. is a leading manufacturer, supplier, and exporter of Carton Stretch Wrapping solutions in India. We actively manufacture and supply advanced carton stretch wrapping machines across major industrial states and cities, including Gujarat (Ahmedabad, Vadodara, Surat, Rajkot), Maharashtra (Mumbai, Pune, Nashik, Aurangabad), Rajasthan (Jaipur, Jodhpur, Udaipur), Madhya Pradesh (Indore, Bhopal), Uttar Pradesh (Noida, Ghaziabad, Lucknow), Delhi NCR (Delhi, Gurugram, Faridabad), Haryana (Panipat, Sonipat), Punjab (Ludhiana, Amritsar), Karnataka (Bengaluru, Hubballi), Tamil Nadu (Chennai, Coimbatore, Madurai), Telangana (Hyderabad), Andhra Pradesh (Visakhapatnam, Vijayawada), and West Bengal (Kolkata, Howrah). We focus on fast delivery, professional installation, and reliable after-sales support to serve diverse industries such as logistics, FMCG, pharmaceuticals, e-commerce, and manufacturing. Our carton stretch wrapping machines protect cartons from dust, moisture, and transit damage while improving packaging efficiency and reducing operational costs across India.

Carton Stretch Wrapping – Overseas Export from India

Innovative WrapTech Pvt. Ltd. actively exports Carton Stretch Wrapping machines from India to a wide range of overseas markets, serving global packaging and logistics industries with reliable and high-performance solutions. We supply advanced carton stretch wrapping machines to customers across the Middle East, including the UAE, Saudi Arabia, and Oman, where demand for secure and efficient packaging continues to grow. Our export network also extends to African countries such as Kenya, Nigeria, and South Africa, as well as Asian markets including Bangladesh, Sri Lanka, and Nepal, along with Southeast Asia and Europe. We design and manufacture our machines in accordance with international quality and safety standards, ensuring strong construction, long service life, consistent wrapping performance, and low maintenance requirements even in demanding industrial environments.

We manage the entire export process with precision, from quality inspection and secure packaging to timely shipment, export documentation, and customs compliance, enabling smooth deliveries to global destinations. Our carton stretch wrapping machines support industries such as FMCG, pharmaceuticals, food & beverage, e-commerce, warehousing, and logistics by protecting cartons from moisture, dust, and transit damage during long-distance transportation. With responsive technical assistance, installation guidance, and dependable after-sales support, Innovative WrapTech Pvt. Ltd. continues to strengthen its reputation as a trusted Indian exporter of carton stretch wrapping solutions, delivering value-driven packaging technology to international clients worldwide.

Why Carton Stretch Wrapping Efficiency Is Critical in Modern Industry

Eliminates manual wrapping variability

Reduces film consumption by up to 40%

Improves packaging line speed and uptime

Enhances carton protection during handling and transport

Supports recyclable and downgauged films

For high-volume operations, manual wrapping is no longer scalable or cost-effective.

Installation Best Practices (Factory-Proven)

Install on vibration-free, level flooring

Align conveyors precisely to prevent carton skew

Ensure stable power supply with surge protection

Allocate access clearance for maintenance

Calibrate sensors and film tension before production

Innovative WrapTech Pvt. Ltd. provides on-site commissioning and operator training to ensure smooth deployment.

Operation Best Practices

Daily:

Verify film alignment and tension

Inspect sensors and emergency stops

Weekly:

Clean rollers and film carriage

Check fasteners and belt tension

Long-Term:

Replace worn rollers and bearings

Update PLC software

Recalibrate pre-stretch ratios

Preventive maintenance directly reduces downtime and film waste.

Safety Standards & Operator Protection

Professional-grade machines comply with:

CE & ISO safety norms

Emergency stop circuits

Safety interlocks and guarding

Operator-safe film threading

Innovative WrapTech machines prioritize human safety without sacrificing speed or efficiency.

Buying Considerations: What Engineers and Plant Heads Evaluate

| Factor | Why It Matters |

|---|---|

| Film pre-stretch capability | Direct impact on material cost |

| Automation level | Labor reduction & consistency |

| Machine uptime | Production reliability |

| Service support | Long-term operational security |

| Integration capability | Future scalability |

FAQs

1. What is carton stretch wrapping efficiency?

Carton stretch wrapping efficiency refers to how effectively cartons are wrapped using stretch film to ensure stability, protection, and reduced material usage while improving packaging speed and consistency.

2. How does carton stretch wrapping improve packaging efficiency?

Carton stretch wrapping improves efficiency by automating the wrapping process, reducing manual labor, minimizing film wastage, and ensuring uniform wrapping for every carton.

3. Which industries benefit most from efficient carton stretch wrapping?

Industries such as FMCG, pharmaceuticals, e-commerce, logistics, food & beverage, and manufacturing benefit the most due to high-volume carton handling and transportation needs.

4. How does carton stretch wrapping reduce product damage?

Carton stretch wrapping secures cartons tightly, preventing movement, exposure to dust, moisture, and impact damage during storage and long-distance transportation.

5. Does carton stretch wrapping help reduce packaging costs?

Yes, efficient carton stretch wrapping reduces packaging costs by optimizing stretch film usage, lowering labor dependency, and decreasing carton damage and returns.

6. Can carton stretch wrapping machines handle different carton sizes?

Modern carton stretch wrapping machines easily handle different carton sizes, weights, and shapes, making them suitable for diverse packaging requirements.

7. How does automation increase carton stretch wrapping efficiency?

Automation increases efficiency by delivering consistent wrapping tension, faster cycle times, reduced downtime, and improved overall productivity.

8. Why is carton stretch wrapping important for exports?

Carton stretch wrapping is crucial for exports because it ensures secure packaging, protects cartons during long transit routes, and meets international packaging and logistics standards.