Decoding the Wrap: An Infographic Guide to Understanding Your Semi-Automatic Pallet Wrapper

Semi-Automatic Pallet Wrappers Explained: A Practical Industrial Guide

Semi-automatic pallet wrappers remain the backbone of pallet packaging across factories, warehouses, and distribution centers. While full automation attracts attention, semi-automatic systems continue to dominate because they balance control, cost, and reliability. At Innovative WrapTech Pvt. Ltd., we design and deploy semi-automatic pallet wrappers that deliver industrial performance without unnecessary complexity.

This guide explains how semi-automatic pallet wrappers work, why they matter, how to operate and maintain them correctly, and how buyers should evaluate the right machine for their operation.

What Is a Semi-Automatic Pallet Wrapper?

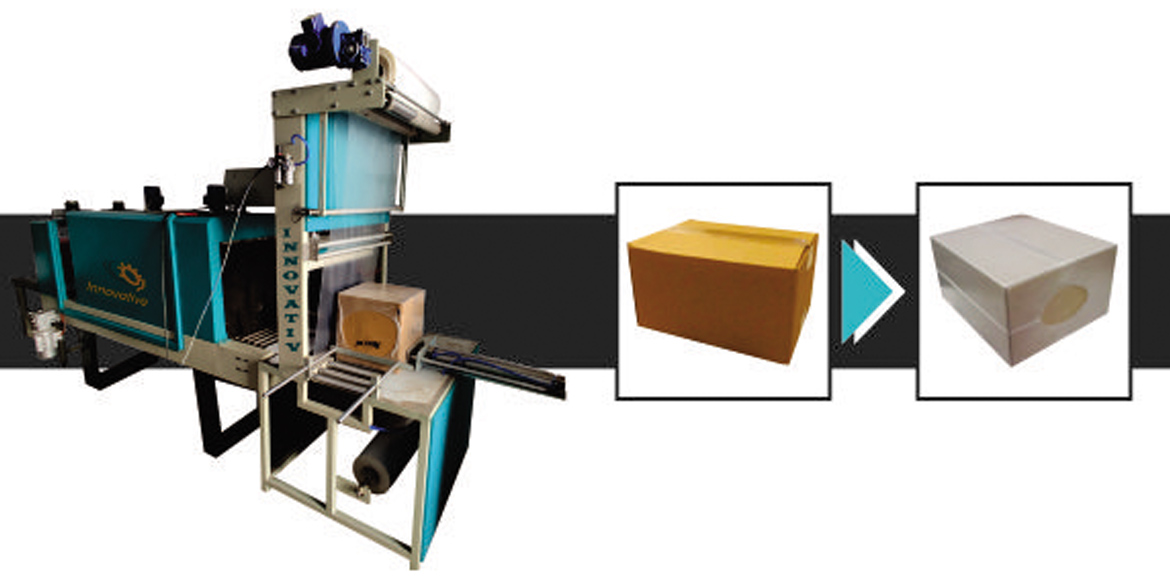

A semi-automatic pallet wrapper is a packaging machine that applies stretch film around a palletized load while requiring limited operator involvement. The operator places the pallet on the machine and initiates the cycle, while the machine controls rotation speed, film tension, and wrap pattern.

These machines provide consistent load containment without the cost and complexity of fully automated systems.

How a Semi-Automatic Pallet Wrapper Works

Step 1: Pallet Placement

The operator positions the pallet on the turntable or wrapping platform using a forklift or pallet truck.

Step 2: Film Attachment

The operator attaches the film tail to the pallet manually at the base.

Step 3: Wrap Cycle Initiation

The operator starts the wrap cycle via control panel or foot switch.

Step 4: Controlled Wrapping

The machine rotates the pallet while the film carriage moves vertically, applying stretch film at preset tension and overlap.

Step 5: Film Cutting

At cycle completion, the operator cuts the film and secures it to the load.

Step 6: Pallet Removal

The wrapped pallet exits the machine, ready for storage or dispatch.

Why Semi-Automated Pallet Wrapping Are Critical in Modern Industry

Manual wrapping introduces:

Inconsistent load stability

High film consumption

Operator fatigue and injury risk

Semi-automatic pallet wrappers deliver:

Up to 30–40% reduction in stretch film usage

Consistent wrap quality across shifts

Improved load safety during transport

Lower labor dependency

Faster throughput than manual methods

Types of Semi-Automated Pallet Wrapping and When to Use Them

1. Turntable Pallet Wrappers

Best for stable, uniform pallet loads

Cost-effective and compact

Ideal for FMCG, warehousing, and logistics

2. Rotary Arm Pallet Wrappers

Designed for light or unstable loads

Keeps pallet stationary

3. Low-Profile Turntable Wrappers

Allows pallet truck loading

Suitable where forklifts are limited

4. Extended Height Models

Handles tall or irregular pallet loads

Common in building materials and furniture

Key Technical Features and Real Operational Benefits

| Feature | Operational Benefit |

|---|---|

| Pre-stretch film system | Reduces film cost |

| Adjustable wrap programs | Improves load consistency |

| Soft start/stop | Prevents load collapse |

| PLC control | Reliable and repeatable performance |

| Height sensing | Ensures full load coverage |

Buying Considerations: What Buyers Should Evaluate

Daily pallet volume

Load stability and weight

Film type and cost

Floor space availability

Operator skill level

Budget vs lifecycle cost

Innovative WrapTech Pvt. Ltd. advises buyers to evaluate total cost of ownership, not just machine price.

Why Manufacturers Prefer Professional-Grade Machines

Low-cost machines often fail due to:

Weak frames

Inconsistent tension control

Limited safety protection

Professional-grade machines deliver:

Predictable performance

Lower downtime

Safer operations

Future Trends and Smart Factory Integration

Semi-Automated Pallet Wrapping continue to evolve through:

Load sensing technology

Digital wrap programs

IoT-ready control systems

Predictive maintenance alerts

These upgrades allow gradual transition toward smart factory environments without full automation.

A semi-automatic pallet wrapper remains the most practical and cost-effective solution for consistent pallet packaging. It bridges the gap between manual labor and full automation while delivering measurable operational benefits.

If your operation values control, reliability, safety, and ROI, a semi-automatic pallet wrapper from Innovative WrapTech Pvt. Ltd. is a proven, future-ready investment.