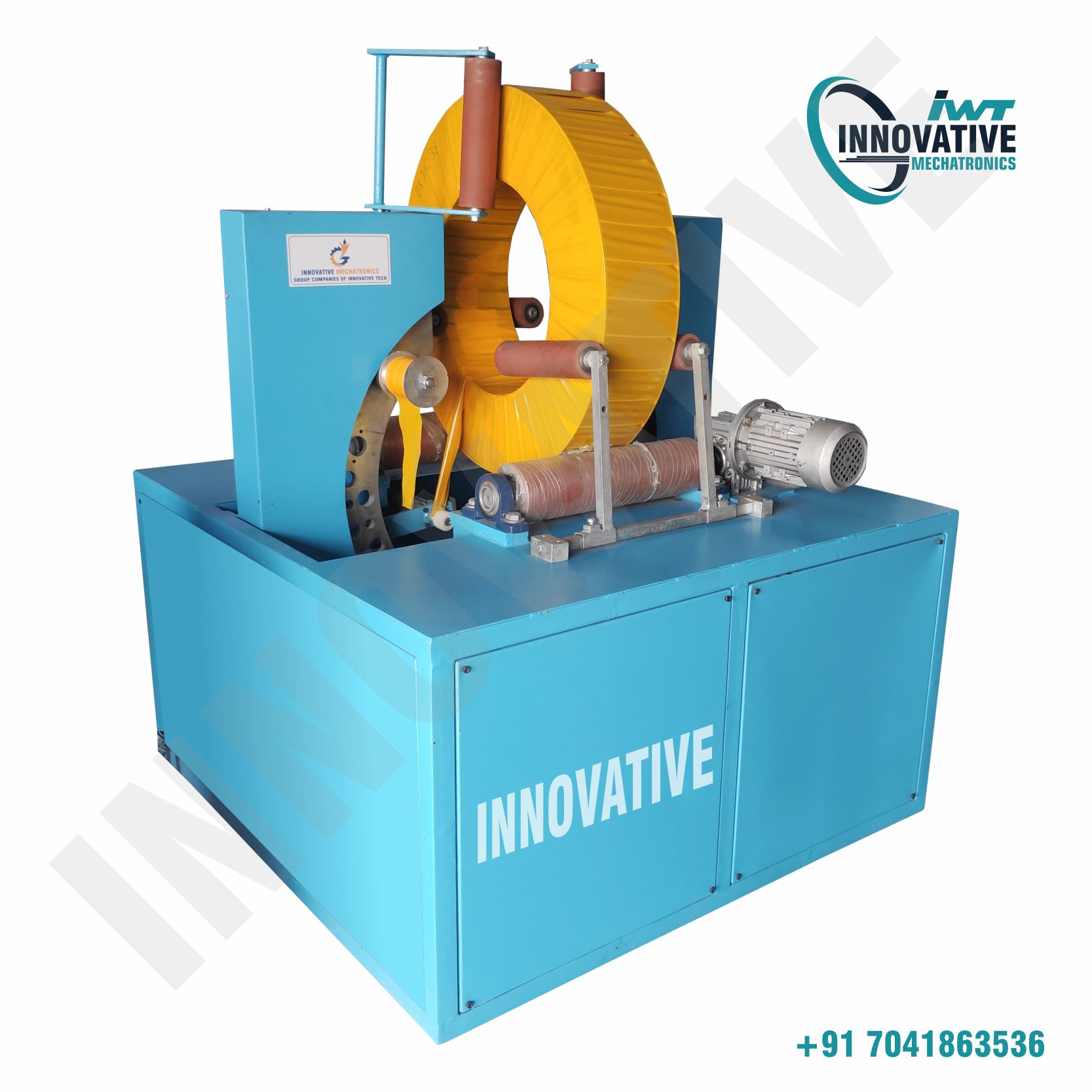

Horizontal Coil Stretch wrapping Machine | Tire Wrapping Machine

Horizontal Coil Stretch Wrapper

What Is a Horizontal Coil Stretch Wrapper?

A horizontal coil stretch wrapper is an industrial packaging machine designed to wrap coils, tires, and cylindrical products horizontally using stretch film. It secures the load with consistent tension, providing load stability, protection from dust and moisture, and safe handling during transport and storage.

Unlike manual wrapping, horizontal coil wrappers automate the process, reducing labor, improving consistency, and minimizing the risk of product damage.

How It Works: Step-by-Step Operational Process

Loading the Coil or Tire

The product is positioned horizontally on the machine’s turntable or conveyor. For heavy coils, forklift or crane loading may be required.Film Attachment

The operator attaches the stretch film to the product or the turntable begins automatic attachment.Tensioning and Pre-Stretch

The motorized system applies controlled tension while pre-stretching the film to minimize material use and ensure tight wrapping without damaging the product.Rotation and Wrapping

The turntable or rotating mechanism spins the coil, allowing the stretch film to wrap evenly around the circumference.Sealing and Cutting (If Applicable)

Some models include automatic sealing or cutting, while others rely on the pre-cut film roll.Completion and Discharge

Once wrapped, the machine stops automatically, and the product is ready for storage or shipping.

Importance in Modern Industrial Operations

Horizontal coil stretch wrappers are critical for modern factories because they:

Reduce labor dependency and operator fatigue

Ensure uniform wrapping, minimizing product damage

Increase throughput for high-volume production

Enhance packaging safety during transport

Enable integration with automated production lines

Compared to manual wrapping, these machines offer higher speed, consistency, and efficiency, while reducing material waste and labor costs.

Types and Variants

| Type | Use Case | Key Advantages |

|---|---|---|

| Manual Horizontal Wrapper | Small workshops or low-volume wrapping | Low cost, flexible operation |

| Semi-Automatic Horizontal Wrapper | Medium-scale production | Controlled tension, reduced labor, moderate speed |

| Automatic Horizontal Wrapper | High-volume industrial production | High speed, minimal operator involvement, precise tension control |

| Inline/PLC-Integrated Wrapper | Fully automated production lines | Data tracking, integration with conveyors, high throughput |

Key Technical Features and Operational Benefits

| Feature | Operational Benefit |

|---|---|

| Adjustable film tension | Prevents coil deformation and ensures tight wrap |

| Motorized turntable | Even, consistent wrapping |

| Pre-stretch system | Reduces film consumption by up to 30% |

| PLC/HMI control | Allows automation and line integration |

| Multi-film compatibility | Works with PP, PET, or PVC films |

| Safety interlocks | Protects operators and prevents accidents |

Standard Technical Specifications

Turntable diameter: 800–2000 mm (depending on model)

Load capacity: 500–5000 kg

Film width: 500–1000 mm

Film thickness: 15–35 microns

Rotation speed: 0–15 RPM adjustable

Power supply: 3-phase, 380–415V, 50/60Hz

Cycle time: 1–5 minutes depending on coil size

Specifications vary by model and manufacturer. Innovative WrapTech Pvt. Ltd. customizes machines to client requirements.

How to Choose the Right Horizontal Coil Stretch Wrapper

Consider:

Load size and weight – heavier or larger coils require stronger turntables

Production volume – high-volume plants benefit from automatic or inline systems

Film type and availability – ensure compatibility with PP, PET, or PVC films

Level of automation – balance between budget and operational efficiency

Budget and ROI – factor in reduced labor and increased throughput

Common Operational Problems and Solutions

| Problem | Solution |

|---|---|

| Uneven wrapping | Adjust turntable speed and film tension |

| Film tearing | Use correct film thickness and pre-stretch settings |

| Coil shifting during rotation | Secure coil with chucks or stabilizing fixtures |

| Operator fatigue | Upgrade to semi-automatic or automatic system |

| Excessive film usage | Calibrate pre-stretch system and tension controls |

Installation, Operation, and Maintenance Best Practices

Installation

Ensure level flooring and space for loading/unloading

Verify power supply, air lines, and ventilation

Align conveyors or turntables correctly

Train operators on safety and workflow

Daily Maintenance

Check sensors and emergency stops

Remove debris from film guides

Weekly Maintenance

Lubricate moving parts

Inspect tensioning and pre-stretch mechanisms

Test motor and control systems

Long-Term Maintenance

Replace worn rollers and belts

Recalibrate tension and speed settings

Conduct full safety audits

Safety Standards and Compliance

ISO 12100 / CE compliant

Emergency stop buttons and safety interlocks

Guarded moving parts and low-voltage controls

Clear operator zones and training

Integrated overload protection

Horizontal coil stretch wrappers from Innovative WrapTech Pvt. Ltd. deliver:

Secure and uniform wrapping for cylindrical products

Scalable automation from semi-automatic to fully inline systems

Reduced labor, lower material waste, and high ROI

Compliance with global industrial safety and quality standards

For manufacturers handling coils, tires, or cylindrical loads, investing in a professional horizontal coil stretch wrapper ensures efficiency, safety, and future-ready automation.

Frequently Asked Questions (FAQ)

1. What is a horizontal coil stretch wrapper?

A horizontal coil stretch wrapper is an industrial machine that wraps coils, tires, and cylindrical products horizontally with stretch film, ensuring secure load stability, protection, and safe handling during transport and storage.

2. Which industries use horizontal coil stretch wrappers?

Industries such as steel, tire manufacturing, cable and wire production, textiles, and rubber products use horizontal coil stretch wrappers to improve packaging efficiency and protect cylindrical products.

3. What types of horizontal coil stretch wrappers are available?

These machines are available as manual, semi-automatic, automatic, and inline/PLC-integrated systems, with selection depending on production volume, product size, and desired automation level.

4. How do horizontal coil stretch wrappers improve operational efficiency?

By automating wrapping, these machines reduce labor requirements, provide consistent tension and film usage, prevent product damage, and increase throughput on production lines.

5. What safety features and compliance standards are included?

Horizontal coil stretch wrappers comply with ISO and CE standards. They include emergency stop buttons, safety interlocks, guarded moving parts, low-voltage controls, and clearly defined operator zones to ensure safe operation.