The Lifeline of Productivity: Why Aftermarket Support is Non-Negotiable for Pallet Wrapper Machines

Maximizing Uptime: The Critical Role of Aftermarket Support for Pallet Wrappers

In modern industrial operations, pallet wrapper machines are more than just equipment—they are productivity lifelines. Downtime, inconsistent performance, or unexpected failures can disrupt supply chains, increase costs, and compromise worker safety. At Innovative WrapTech Pvt. Ltd., our experience shows that aftermarket support is not optional—it’s essential for maintaining operational efficiency and safeguarding ROI.

This guide explores the technical operation of pallet wrappers, the importance of after-sales support, and practical guidance for choosing, operating, and maintaining these machines in industrial environments.

What Is a Pallet Wrapper Machine and How Does It Work?

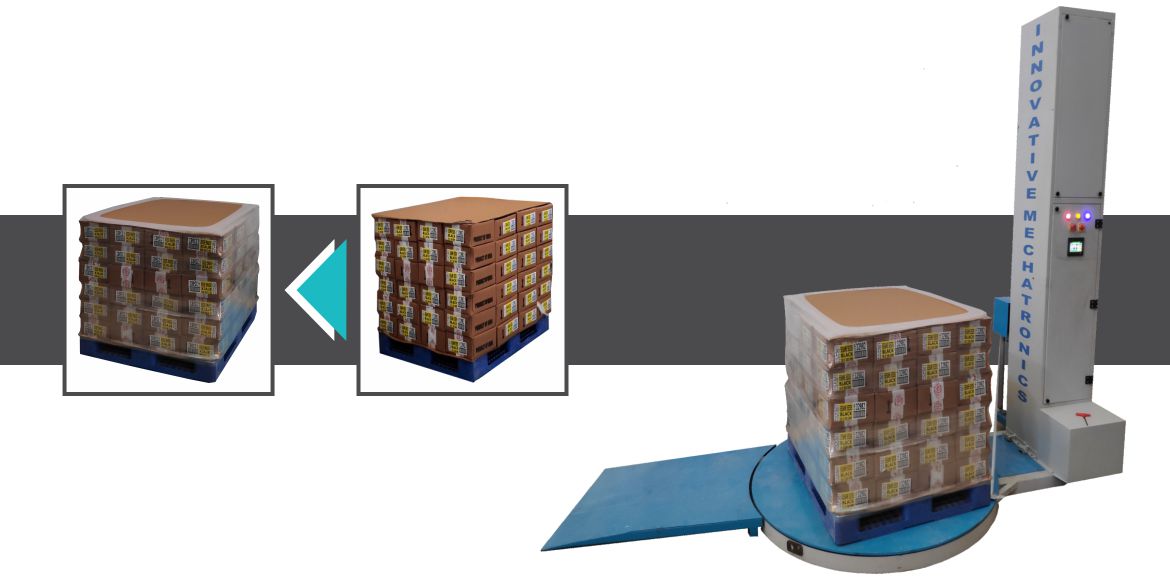

A pallet wrapper machine stabilizes palletized loads by automatically wrapping them with stretch film. It improves load integrity, reduces damage during storage and transit, and ensures consistent packaging quality across production lines.

Pallet Placement

Operators or automated conveyors place the pallet in the machine’s wrapping zone.Load Detection

Sensors detect pallet dimensions, weight, and profile for customized wrapping cycles.Film Attachment

The film tail is anchored to the pallet base to prevent slippage.Base Wrapping

The machine applies tight wraps at the base to anchor the load.Vertical Wrapping Cycle

Turntable or rotary arm rotates the pallet while the film carriage moves vertically for full coverage.Top Layer Reinforcement

Additional wraps secure the top layers for maximum stability.Film Cut & Clamp

Automated systems cut and clamp the film, completing the wrapping cycle.Pallet Exit

Wrapped pallets exit ready for storage or shipment.

Why Pallet Wrappers Are Critical in Modern Industrial Operations

Modern operations demand speed, consistency, and safety. Pallet wrappers provide:

Consistent Load Stability – Prevents product shifting and damage.

Labor Efficiency – Reduces manual handling and operator fatigue.

Cost Savings – Minimizes film usage with pre-stretch technology.

Operational Scalability – Handles high-volume production with repeatable performance.

Manual wrapping methods cannot match the precision, speed, or reliability of automated or semi-automated machines.

Types of Pallet Wrapper Machines and Their Use Cases

1. Semi-Automatic Wrappers

Use when: Moderate volume operations with occasional manual intervention

Benefit: Cost-effective and flexible for changing SKUs

2. Fully Automatic Wrappers

Use when: High-volume, continuous operations

Benefit: Minimal human intervention, maximum throughput

3. Rotary Arm Wrappers

Use when: Lightweight or unstable loads

Benefit: Keeps pallets stationary while wrapping, preventing toppling

4. Ring-Type Wrappers

Use when: Fast wrapping of high-volume, uniform loads

Benefit: High-speed operation with compact machine footprint

Choosing the Right Pallet Wrapper Machine

Capacity & Volume – Match speed and size to production requirements

Load Type – Rotary arms for unstable or delicate pallets

Automation Level – Semi-automatic for flexible lines, fully automatic for high throughput

Material & Film Type – Ensure compatibility with load type and film grade

Budget vs ROI – Factor in labor savings, film reduction, and downtime prevention

Aftermarket Support: The Non-Negotiable Lifeline

Experience shows that even the best machines require regular support. Aftermarket services from Innovative WrapTech Pvt. Ltd. include:

Spare parts availability

On-site technical support

Preventive maintenance contracts

Remote diagnostics and troubleshooting

This ensures continuous uptime, cost control, and sustained productivity, which is critical for industrial operations.

Pallet wrapper machines are industrial workhorses, but their productivity depends on expert operation, preventive maintenance, and reliable aftermarket support. Investing in machines without considering these factors risks downtime, increased costs, and compromised safety.

At Innovative WrapTech Pvt. Ltd., we combine machine engineering excellence with unmatched after-sales support, ensuring your pallet wrapping operations are efficient, safe, and future-ready.

FAQs – Aftermarket Support for Pallet Wrapper Machines

Q1. What is aftermarket support for pallet wrapper machines?

Aftermarket support includes spare parts, preventive maintenance, on-site service, and troubleshooting after machine installation. It ensures continuous uptime, reduces unexpected downtime, and protects operational investment.

Q2. Why is aftermarket support critical for industrial operations?

Industrial pallet wrapper machines are central to productivity. Without reliable after-sales service, breakdowns can halt production, increase costs, and compromise safety. Aftermarket support guarantees smooth, uninterrupted operations.

Q3. What types of aftermarket services are typically offered?

Common services include preventive maintenance contracts, emergency repair, remote diagnostics, spare parts supply, and operator training. Tailored services from Innovative WrapTech Pvt. Ltd. ensure machines perform optimally for years.

Q4. How does aftermarket support improve machine efficiency?

Support ensures timely maintenance, correct part replacement, and rapid troubleshooting, which prevents production delays, reduces film waste, and maintains consistent wrapping quality.

Q5. How do I choose the right after-sales support for my pallet wrapper machine?

Evaluate service response time, spare parts availability, preventive maintenance programs, and experience of the service provider. Choose a partner like Innovative WrapTech Pvt. Ltd., with a proven track record in industrial pallet wrapping solutions.