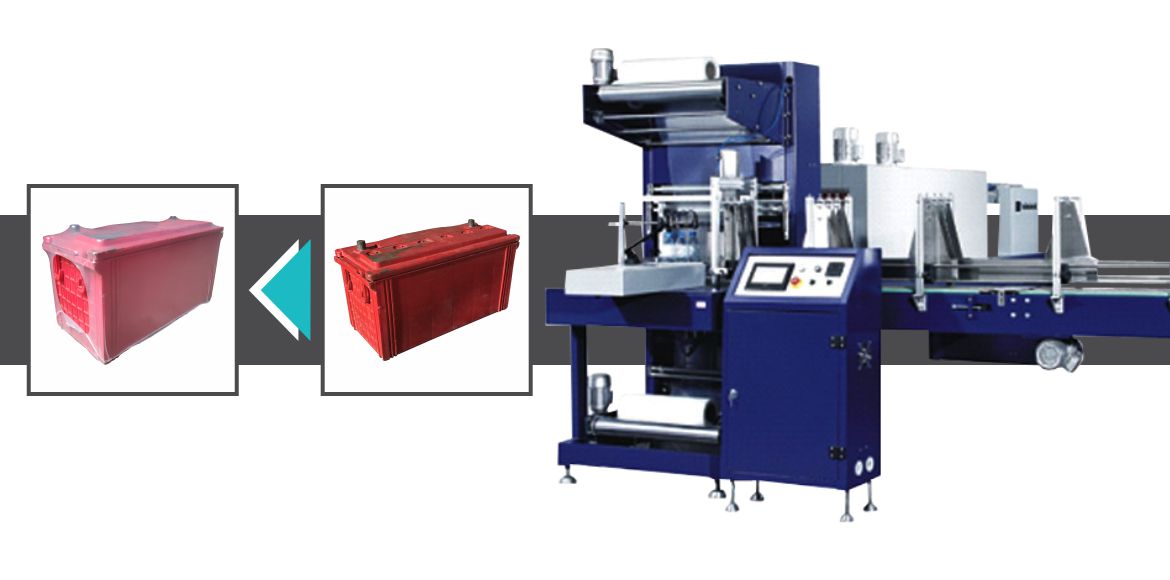

Automatic battery shrink wrapping machine uses to packing big battery like inverter battery, car battery,

truck battery.

we make all type customize types of battery packing machine.

battery packing wide use for last 2 year because battery corrugated packing cost is very high compare to shrink packing .

also good looking box pack battery to shrink pack battery.

Automatic Battery Shrink Wrapping

Automatic Battery Shrink Wrapping is an industrial packaging process that tightly wraps batteries in heat-shrink film to create a secure, tamper-resistant, and transport-safe pack. Manufacturers use this system to package automotive batteries, inverter batteries, lithium battery packs, and industrial cells with consistent quality and high output.

Innovative WrapTech Pvt. Ltd. designs these machines to handle heavy battery loads, maintain electrical safety, and ensure uniform shrink results without damaging battery casings.

How the Machine Works – Step-by-Step Technical Operation

Battery Infeed

The machine receives batteries automatically through a conveyor or robotic infeed system.Positioning & Spacing Control

Sensors detect battery size and spacing to maintain correct film coverage.Film Dispensing & Wrapping

The system feeds LDPE shrink film and wraps it tightly around individual batteries or grouped packs.Sealing Process

Heavy-duty sealing jaws create strong, uniform seals without overheating.Shrink Tunnel Heating

Batteries move through a temperature-controlled shrink tunnel.Controlled Shrinking

Heat shrinks the film evenly while protecting battery terminals and casing.Cooling & Discharge

Cooling fans stabilize the pack before discharge onto the output conveyor.

Why This Machine Is Critical in Modern Industrial Operations

Battery manufacturers operate in high-risk, high-value environments. Automatic shrink wrapping:

Reduces manual handling of heavy batteries

Prevents short circuits and terminal exposure

Improves transport safety and stack stability

Delivers uniform, export-ready packaging

Increases output while lowering labor cost

Compared to manual wrapping or carton-only packing, shrink wrapping offers better protection, faster throughput, and lower rejection rates.

Types and Variants of Automatic Battery Shrink Wrapping Machines

Semi-Automatic Battery Shrink Wrapping

Manual loading with automatic sealing and shrinking

Suitable for low to medium production volumes

Fully Automatic Battery Shrink Wrapping

Conveyor-based continuous operation

Ideal for large battery plants and export lines

Multi-Pack Battery Shrink Wrapping

Wraps battery sets for OEM supply

Ensures uniform grouping and load stability

Customized Heavy-Duty Models

Designed for high-weight industrial batteries

How to Choose the Right Automatic Battery Shrink Wrapping Machine

Capacity Requirement

Match machine speed with daily production targets.

Battery Size & Weight

Select a model designed for your heaviest battery type.

Level of Automation

Semi-automatic for flexibility

Fully automatic for high-volume consistency

Safety Features

Ensure terminal protection and electrical safety compliance.

Budget & ROI

Consider labor savings, damage reduction, and output increase.

Installation, Operation, and Maintenance Best Practices

Installation

Maintain safe clearance around shrink tunnel

Ensure proper earthing and power stability

Operation

Use recommended LDPE film thickness

Monitor tunnel temperature continuously

Keep battery terminals protected during wrapping

Maintenance

Clean sealing jaws weekly

Inspect heaters and conveyors regularly

Calibrate sensors every quarter

Safety Standards, Compliance & Operator Protection

Innovative WrapTech Pvt. Ltd. designs machines in line with:

Industrial electrical safety norms

Emergency stop and interlock systems

Overload protection for conveyors

Operator guarding and warning indicators

Proper training and PPE ensure long-term safe operation.

Frequently Asked Questions (FAQs)

1. What does this machine package?

This machine is designed to shrink wrap single or multiple batteries, providing dust-proof, moisture-proof, and tamper-evident packaging while ensuring safe handling and transportation.

2. Can it handle different battery sizes?

Yes. Adjustable guides and conveyor settings allow the machine to accommodate various battery dimensions without affecting shrink quality.

3. Which types of shrink films are compatible?

The machine supports PVC, PE (Polyethylene), and POF (Polyolefin) shrink films. POF film is preferred for clarity, strength, and professional appearance.

4. What is the production capacity?

Depending on the model, the machine can process approximately 300–800 batteries per hour for standard sizes.

5. Is the machine easy to operate and maintain?

Yes. Minimal training is required. Operators can adjust temperature, conveyor speed, and sealing settings easily. Routine maintenance involves cleaning, inspecting sealing blades, and checking heating elements.