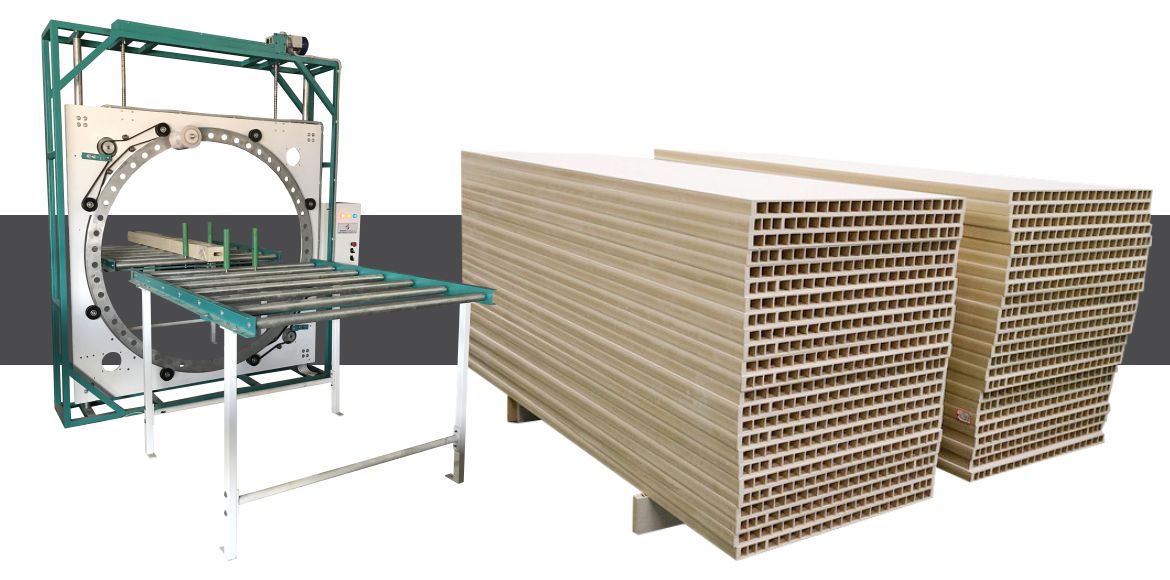

Big Product Orbital Packing Machine are ideal for long loads that can not be stretch wrapped on a conventional turntable or rotary tower type machine.

Examples of products that are well suited for orbital wrapping pipe, plastic extrusions, carpet rolls, lumber, aluminum siding, and many other long products.

Ring sizes from 15 inch to 90 inch are available to accommodate virtually all orbital wrapping applications.

Big Product Orbital Packing Machine

The Big Product Orbital Packing Machine is an industrial packaging solution designed to wrap large, heavy, or bulky products with protective stretch film, foam-laminated sheets, or other packaging materials. It ensures uniform coverage, edge and surface protection, and secure handling during storage, transport, or dispatch.

Manufacturers and warehouses use it to replace manual packing, reduce labor, and maintain consistent, high-quality packaging for heavy industrial products.

Importance in Modern Industrial Operations

Handles heavy, bulky, and irregularly shaped products safely and consistently

Reduces manual labor and fatigue

Provides uniform, export-grade packaging

Protects products from scratches, dust, moisture, and edge damage

Improves logistics efficiency and storage safety

By automating heavy product wrapping, manufacturers save time, labor costs, and materials while enhancing safety and quality.

Types & Variants

| Type | Application |

|---|---|

| Manual Orbital Packing | Operator manually wraps products; suitable for low-volume operations |

| Semi-Automatic Orbital Packing | Operator loads product; machine wraps automatically; ideal for medium-volume production |

| Fully Automatic Orbital Packing | Conveyor-fed, minimal human intervention; designed for high-volume industrial operations |

| Horizontal / Vertical Orbital Wrapping | Horizontal systems suit long products; vertical systems handle tall or bulky items efficiently |

Key Technical Features & Operational Benefits

| Feature | Operational Benefit |

|---|---|

| Pre-stretch film unit | Reduces film usage by up to 50% |

| PLC & HMI controls | Ensures precise, repeatable wrapping cycles |

| Adjustable wrapping speed | Protects fragile or irregular products |

| Heavy-duty rollers & supports | Handles bulky or heavy products safely |

| Automatic film cutter | Increases productivity and safety |

| Soft-start motor | Prevents product shift or damage |

How to Choose the Right Model

Capacity: Match throughput with production volume

Product Size & Weight: Ensure rollers, supports, and motor strength meet load requirements

Material Type: Check compatibility with stretch film, foam, or paper wrapping

Automation Level: Choose manual, semi-automatic, or fully automatic depending on production scale

Budget: Consider ROI from labor savings, reduced product damage, and material efficiency

Floor Space: Horizontal or vertical designs based on available factory layout

Conclusion

The Big Product Orbital Packing Machine provides efficient, safe, and uniform packaging for heavy and bulky industrial items. It reduces labor, minimizes damage, optimizes material usage, and is essential for manufacturers seeking high-quality, automated, and export-ready packaging solutions.

FAQs

1. What is a Big Product Orbital Packing Machine?

It is an industrial machine designed to wrap large, heavy, or bulky products using stretch film, foam-laminated sheets, or protective materials, ensuring uniform coverage and surface protection.

2. How does the machine work?

The machine aligns the product, feeds protective film with controlled tension, rotates an orbital arm or ring around the product, cuts and seals the film automatically, and discharges the wrapped product ready for storage or shipping.

3. What types of products can it wrap?

The machine handles industrial machinery, metal components, furniture, appliances, modular kitchen items, and construction materials of varying size and weight.

4. What are the energy and power requirements?

Voltage: 380–415V, 3-phase, 50/60 Hz

Power Consumption: 3–7 kW depending on model

The machine uses pre-stretch film technology, reducing energy use and operational costs per product.

5. Can it wrap products of different sizes?

Yes. Adjustable rollers, programmable settings, and sensors allow the machine to wrap products of various lengths, widths, heights, and weights efficiently.