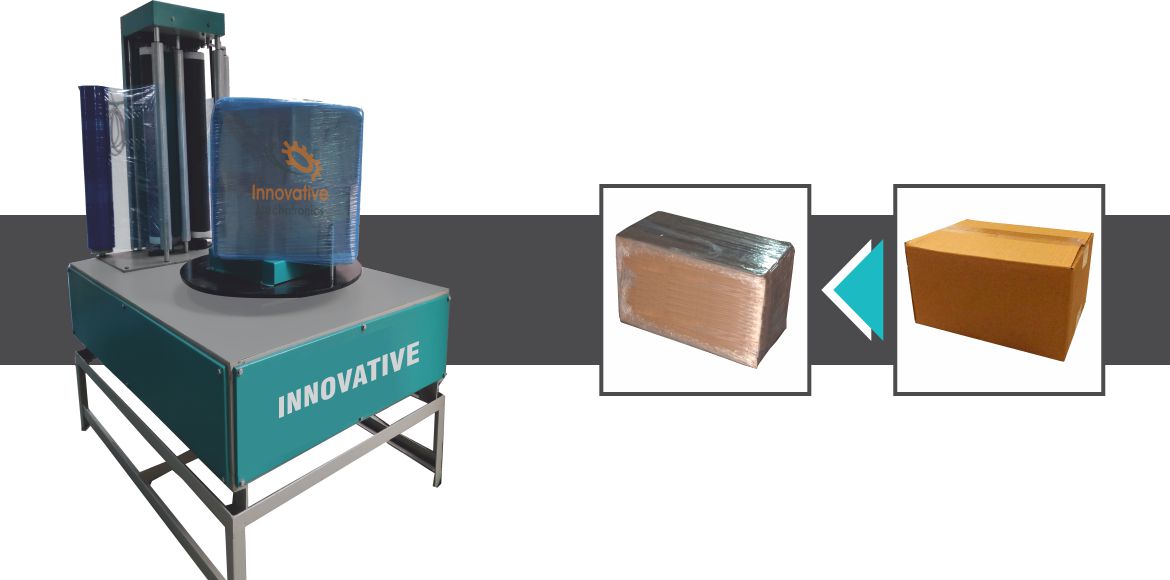

Box wrapping machine with pre-stretch system:-

When your production rate is high and film consumption in packing is also more then you should purchase carton wrapping with pre-stretch system.

With the help of pre-strtech system you can save film upto 200 to 300%. But as same as simple machine the maximum size 20*20*30inch and weight 15kg to 50kg can work.

If your carton’s any 2 side is less than 20inch like it can be height, weight or length anything and third size is bigger than 20inch but less than 30inch then we can use this model.

Advantages:-

1.) Film-saving upto 300%

2.) Protection from Dust, Moisture & foreign particles

3.)Eye-catching Packaging

Box Pre-Stretch Wrapper Machine

The Box Pre-Stretch Wrapper Machine is an industrial packaging machine designed to securely wrap cartons and boxes using pre-stretched stretch film. By pre-stretching the film before application, the machine provides uniform tension, better load stability, and reduced film usage, ensuring efficient, damage-free packaging.

Step-by-Step Operation:

Load Boxes: Place cartons or boxes evenly on a pallet or conveyor.

Install Film Roll: Mount the pre-stretch film on the carriage system.

Set Wrapping Parameters: Choose wrapping cycles, speed, and number of layers.

Start the Wrapping Cycle: The film carriage applies pre-stretched film while moving vertically (up and down) around the boxes.

Adjust Tension if Needed: Ensure the film holds boxes firmly without crushing them.

Cut and Clamp Film: Automatically completes the cycle.

Ready for Dispatch: The pallet or stack of boxes is stable, secure, and ready for storage or shipment.

Types and Variants

Semi-Automatic Pre-Stretch Wrapper

Operator starts and stops each cycle manually.

Fully Automatic Pre-Stretch Wrapper

Integrates with conveyor lines for continuous high-volume operations.

Best for large-scale factories and smart manufacturing setups.

Rotary Arm Pre-Stretch Wrapper

Arm rotates around a stationary pallet for tall or irregular loads.

Suitable for heavy or delicate items requiring minimal handling.

Key Technical Features and Operational Benefits

| Feature | Operational Benefit |

|---|---|

| Pre-stretch film carriage | Reduces film usage by 30–50% and ensures uniform tension |

| Adjustable tension | Prevents box crushing and improves load stability |

| PLC or touchscreen controls | Simplifies operation and cycle customization |

| Vertical up-down movement | Ensures full coverage from top to bottom |

| Automatic film cut & clamp | Speeds up wrapping and reduces manual handling |

| Emergency stop and safety sensors | Protects operators from accidents |

Industries and Real-World Applications

E-commerce & Logistics: Securing cartons for shipping and storage.

FMCG & Retail Packaging: Wrapping consumer goods.

Pharmaceutical & Electronics: Protecting delicate products during transit.

Food Processing & Agriculture: Stabilizing packaged food cartons.

Warehousing & Distribution Centers: Efficient pallet preparation for high-volume operations.

How Buyers Can Choose the Right Model

Capacity: Match machine capacity to pallet weight and load size.

Material: Ensure compatibility with box type and fragility.

Automation Level: Semi-automatic for low-medium volume; fully automatic for high-volume lines.

Budget: Balance upfront cost with labor savings, reduced damage, and increased throughput.

Common Operational Problems and Solutions

Film tearing: Adjust tension and replace low-quality film.

Uneven wrapping: Align boxes properly and calibrate the carriage.

Load instability: Add extra wrapping layers or use anti-slip pads.

Operator errors: Provide training and use automatic control features.

Frequently Asked Questions (FAQ)

Q1: What is the energy and power requirement of the machine?

The Box Pre-Stretch Wrapper Machine operates on 220V single-phase or 380V three-phase power and uses energy-efficient motors to minimize electricity consumption and operational costs.

Q2: Can the machine handle different box sizes?

Yes, the machine handles multiple box sizes using adjustable film tension and vertical up-down carriage movement for secure, consistent wrapping.

Q3: How long is the expected service life of the machine?

With proper operation and routine maintenance, the machine delivers 10–15 years of reliable service, offering excellent long-term ROI.

Q4: Is operator training required?

Yes, basic operator training ensures safe loading of boxes, proper adjustment of tension, and efficient operation of the machine.

Q5: Can this machine integrate with existing production lines or ERP systems?

Yes, fully automatic models integrate seamlessly with conveyor systems, production lines, and ERP setups, making it ideal for smart factories and Industry 4.0 operations.