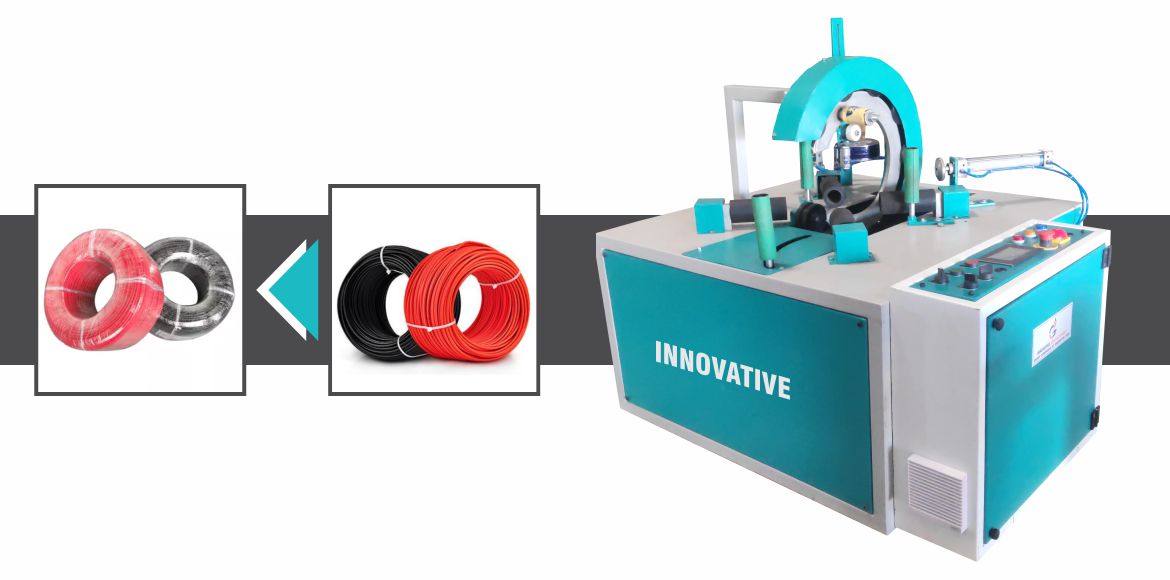

The COIL STRETCH WRAPPING MACHINE also called Wire & Cable Film Wrapping Machine is used for Spiral / Periphery Stretch Wrapping of Coil Shaped Products and Products with Long Lengths.

Wire & Cable Film Wrpapping machine use To wrapping 2 Kg To 50 Kg wire bandal Film Wrapping. ID : 150 To 500 MM, OD: 200 To 700 MM and Width : 20 To 100 MM.

The machine offers various controls for wrapping the stretch film and jute/paper roll at desired wrap tension and for wrapping different wrap configurations. The machine is designed for continuous operation and is rigid & sturdy. The machine is designed with an emphasis of functionality, reliability, and ease of operation.

Coil wrapper wraps the coil-shaped products in a spiral manner through the eye of the product. This is a means of applying the stretch film to a load consisting of stretch rollers supported on a vertical ring. It has a means of passing a load through ring’s eye horizontally.

Cable Wrapping Machine Industrial

What Is a Cable Wrapping Machine Industrial?

A Cable Wrapping Machine Industrial is a specialized packaging system designed to securely wrap industrial cables, wires, and optical fiber coils on spools or pallets. The machine applies controlled stretch or protective film to prevent tangling, abrasion, dust contamination, and damage during storage and transportation.

It is ideal for large-scale cable manufacturers, distributors, and electrical component warehouses, ensuring consistent packaging quality and operational efficiency.

Why This Machine Is Important in Modern Industrial Operations

Industrial cable handling requires precision, safety, and protection of high-value products. Manual wrapping is labor-intensive, inconsistent, and risks product damage.

Key Industrial Benefits

Maintains coil and cable integrity during transport

Prevents tangling, surface damage, and moisture exposure

Enhances warehouse safety and load stability

Reduces labor costs and increases packaging speed

Delivers uniform wrapping for export-ready packaging

A Cable Wrapping Machine Industrial transforms cable packaging into a safe, repeatable, and professional process.

How to Choose the Right Cable Wrapping Machine

1. Capacity and Cable Size

Verify maximum cable spool diameter, width, and weight

Choose reinforced frames and turntables for heavy industrial spools

2. Material Compatibility

Supports stretch film, shrink film, or protective wrapping sheets

Adjustable tension prevents cable deformation or spool damage

3. Automation Level

Manual/Semi-Automatic: Suitable for medium production lines

Fully Automatic: Ideal for high-throughput cable manufacturing operations

4. Budget and ROI

Professional-grade machines reduce film waste and labor costs

Minimize downtime while increasing throughput for long-term savings

Safety Standards, Compliance, and Operator Protection

Innovative WrapTech Pvt. Ltd. builds machines with operator safety and compliance as a priority.

Standard Safety Features

Emergency stop buttons for immediate shutdown

Stable turntables and clamping systems to prevent spools from tipping

Smooth film carriage movement to reduce operator fatigue

Compliance Standards

CE-certified components

ISO-certified manufacturing

IEC-compliant electrical and control systems

These safety measures ensure reliable and secure operation in industrial environments.

Why Manufacturers Prefer Professional-Grade Machines

Professional Cable Wrapping Machines Industrial outperform low-quality models in durability, efficiency, and safety.

Key Advantages

Consistent wrapping tension for all cable types

Reliable operation under continuous use

Reduced maintenance and downtime

Ergonomic and safe for operators

Seamless integration with warehouse or conveyor systems

Manufacturers rely on professional machines to ensure product quality, protect investment, and boost operational efficiency.

Frequently Asked Questions (FAQ)

1. What are the energy and power requirements?

Most industrial cable wrapping machines operate on 3-phase power, with consumption ranging from 1.5 kW to 3.5 kW, depending on automation and spool size.

2. Can the machine handle different cable diameters?

Yes. Adjustable parameters allow wrapping multiple spool sizes and diameters.

3. Does it prevent cable damage?

Yes. Controlled tension and stable rotation prevent tangling, deformation, and surface scratches.

4. Is operator training required?

Yes. Minimal training ensures safe handling and optimal wrapping quality.

5. Can the machine support export packaging?

Yes. It provides stable, secure, and damage-resistant wrapping suitable for global shipping.

Conclusion

A Cable Wrapping Machine Industrial from Innovative WrapTech Pvt. Ltd. ensures safe, efficient, and consistent packaging of industrial cables. It protects products, reduces labor dependency, improves operational efficiency, and meets modern industrial safety standards.