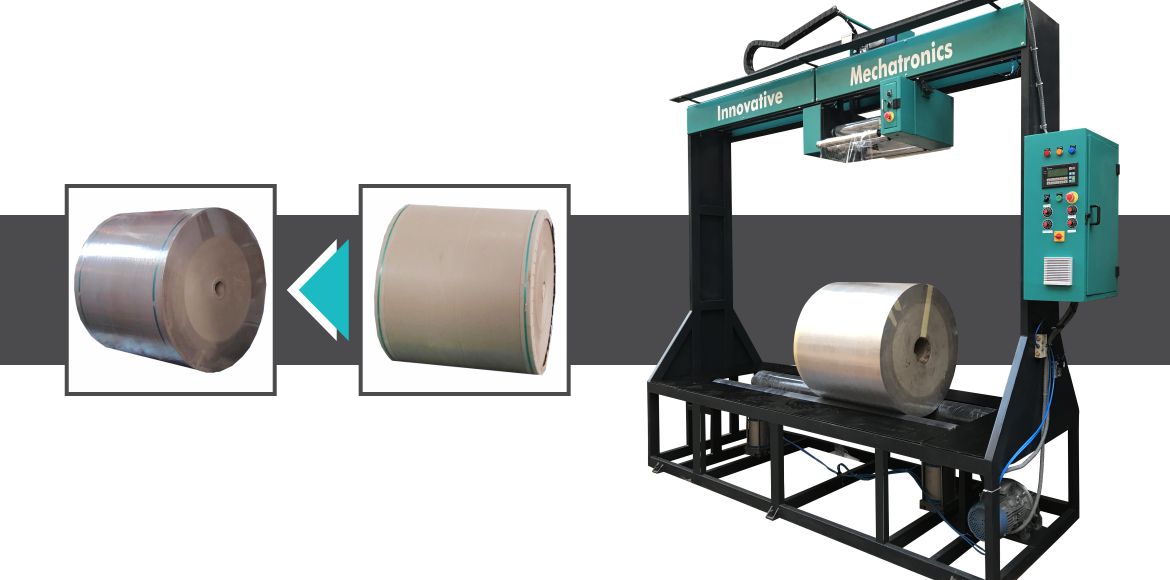

Laminated Bottom Paper Roll Stretch Wrapping Machine use to film packing on a big paper roll. redial type roll packing machine wrap outer surface film packing use.

after using redial wrapping machine product packing value increases. similarly, most advantage of save film up to 300 % than manual roll packing.

About Radial Reel Stretch Wrapping Machine

Radial Reel Stretch Wrapping Machine is widely used in the paper and fabric industry where raw jumbo rolls are manufactured and packed.

In radial type machine, reels are wrapped on its cylindrical surface only, side portions are bear and can be covered with paper rings.

It allows minimum film consumption in compare to traditional axial reel wrapping machine. We manufactured machine according to buyers reel sizes and weights.

Laminated Paper Roll Wrapping

A Laminated Paper Roll Wrapping Machine is an industrial system designed to wrap laminated bottom paper rolls with stretch film or protective materials. It ensures complete coverage of the roll, protecting it from moisture, dust, mechanical damage, and contamination during storage, handling, and transportation.

This machine delivers uniform tension, consistent wrapping, and professional packaging, which manual methods cannot achieve efficiently. Paper manufacturers, converters, and export-oriented packaging operations rely on it for superior protection and reliability.

Why Is This Machine Important in Modern Industrial Operations?

Modern industries require speed, consistency, and protection. The Laminated Paper Roll Wrapping Machine addresses these demands by:

Enhancing Efficiency: Wraps laminated paper rolls faster than manual methods.

Reducing Product Damage: Protects rolls from moisture, dust, and physical damage.

Lowering Labor Costs: Minimizes manual handling and operator fatigue.

Ensuring Consistency: Delivers uniform wrapping for every roll.

Supporting High-Volume Production: Handles continuous industrial operations with precision.

Using this machine improves logistics efficiency, reduces rejections, and ensures professional-quality packaging for domestic and export markets.

How to Choose the Right Laminated Paper Roll Wrapping Machine

1. Capacity

Select a machine that supports your typical roll diameter, width, and weight. Heavy-duty models handle jumbo laminated rolls efficiently.

2. Material Compatibility

Ensure compatibility with laminated paper, coated paper, or specialty paper types.

3. Automation Level

Semi-Automatic Machines: Suitable for moderate production volumes.

Fully Automatic Machines: Ideal for continuous high-speed operations.

4. Budget

Balance initial investment with long-term efficiency, lower labor costs, and reduced material wastage.

5. Customization Options

Look for adjustable film tension, end-face wrapping, and integration with conveyors for optimized workflow.

Key Technical Features & Operational Benefits

Technical Features

Heavy-duty steel frame

Adjustable stretch film tension

Smooth rotation with roller or conveyor handling

Semi-automatic and fully automatic models

Compact and space-efficient design

Operational Benefits

Faster wrapping cycles

Reduced film consumption

Improved product protection

Enhanced storage and transportation efficiency

Frequently Asked Questions (FAQ)

Q1: How does the Laminated Paper Roll Wrapping Machine work?

A: Operators place the laminated roll on the machine. The system rotates the roll while the film wraps it evenly, ensuring complete protection.

Q2: What types of laminated paper rolls can it handle?

It supports laminated paper, coated paper, and specialty rolls of various sizes and weights.

Q3: Is it suitable for high-volume industrial operations?

Yes. Fully automatic models handle continuous high-speed packaging.

Q4: What is the typical price range of this machine?

Prices range from ₹2,00,000 to ₹10,00,000, depending on automation, roll capacity, and customization. Innovative WrapTech Pvt. Ltd. provides customized quotations based on operational needs.

Q5: How is the machine maintained?

Routine cleaning, lubrication, tension calibration, and inspection of rollers ensure long-term performance.