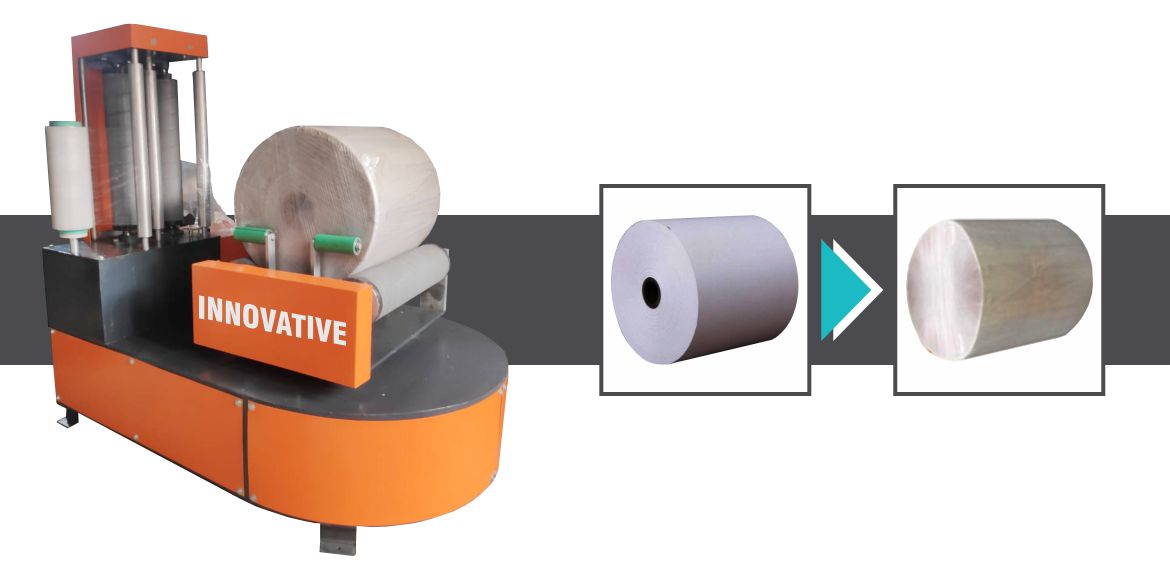

LAMINATED ROLL STRETCH PACKING MACHINE is used for stretch film wrapping around the Laminated roll ,small Bottom Roll, Big paper bottom Roll , Paper product and similar materials manufactured in small reels. Reel Stretch wrapping machine assist in reduction of labor by automating the process of attaching, detaching and pressing the film. For the product to be wrapped, the operator simply places the item on a turn-table and switches the machine to operate.

IM-003 Reel wrapping machine With pre-stretch unit system use to wrap Bottom Paper , small paper roll , flat drip pipe, laminated roll , small width paper roll.

Main advantage of IM-003 save film up-to 300 %.

we provide Holding system for small width product

Laminated Roll Stretch Packing Machine

What Is Laminated Roll Stretch Packing?

Laminated Roll Stretch Packing is an industrial packaging process that uses controlled stretch film wrapping to protect laminated rolls—such as flexible packaging films, paper laminates, aluminum-based laminates, and multi-layer industrial sheets—during storage and transportation.

Manufacturers rely on this system to maintain surface integrity, edge protection, and roll stability, especially for products that are sensitive to moisture, dust, scratches, and handling damage.

Why Laminated Roll Stretch Packing Is Critical in Modern Industrial Operations

Modern packaging plants handle high-value, precision-finished rolls that cannot tolerate surface defects. Manual packing methods fail to deliver consistent tension, uniform coverage, or repeatable quality.

Laminated Roll Stretch Packing:

Protects premium laminated surfaces from abrasion and contamination

Maintains roll shape and edge alignment

Supports export-grade packaging standards

Enables faster dispatch with consistent quality

This process plays a vital role in flexible packaging, printing, FMCG, and export manufacturing units.

How Laminated Roll Stretch Packing Works

Step 1: Roll Loading

The operator places the laminated roll on support rollers, V-cradles, or conveyor beds, ensuring proper centering and balance.

Step 2: Parameter Setting

The control system sets:

Roll diameter and width

Wrapping pattern

Film tension and overlap ratio

These settings ensure uniform coverage without damaging the laminate.

Step 3: Stretch Film Pre-Stretch

A powered pre-stretch unit elongates the film, typically 150% to 300%, increasing holding force while minimizing film consumption.

Step 4: Controlled Wrapping Cycle

The roll rotates while the film carriage moves laterally or vertically

The machine applies consistent tension across the roll surface

Edge zones receive reinforced wrapping for impact resistance

Step 5: Film Cutting and Sealing

At cycle completion, the system cuts and secures the film, leaving a clean, professional finish suitable for warehousing or shipment.

Step 6: Roll Discharge

The wrapped roll exits the machine, ready for palletizing, labeling, or export packing.

Key Industrial Benefits for Buyers

Protects high-value laminated surfaces

Reduces packaging material waste

Improves dispatch speed and reliability

Enhances export packaging compliance

Delivers strong return on investment

Industries That Use Laminated Roll Stretch Packing

Printing and lamination plants

Paper and film converters

FMCG packaging units

Export-oriented manufacturing industries

Frequently Asked Questions (FAQ)

Laminated Roll Stretch Packing

1. What is Laminated Roll Stretch Packing?

Laminated Roll Stretch Packing is an industrial packaging process that uses stretch film to tightly wrap laminated rolls, protecting them from dust, moisture, surface damage, and handling impacts during storage and transportation.

2. Which types of laminated rolls can be packed using this system?

This packing method handles:

Flexible packaging film rolls

Paper and aluminum laminated rolls

Plastic and multi-layer laminate rolls

Printed and coated industrial rolls

It works effectively for both light-duty and heavy-duty rolls.

3. Why is stretch packing preferred over manual packing for laminated rolls?

Stretch packing ensures:

Uniform film tension

Consistent surface protection

Reduced labor effort

Faster packing cycles

Manual packing cannot deliver the same level of consistency or efficiency.

4. How does Laminated Roll Stretch Packing protect roll edges?

The machine applies controlled overlap and reinforced wrapping at the edges, preventing deformation, tearing, and impact damage during transport and stacking.

5. How does this system reduce labor costs?

The system allows a single operator to manage the entire packing process. It eliminates heavy manual handling, reduces overtime, and minimizes errors, resulting in significant labor cost savings.