Binding Wire Film Wrapping Machine Manufacturer for steel binding wire wrapping machine iron binding wire packing machine galvanized binding wire wrapping machine Industrial Binding Steel binding wire wrapping machine new

please watch: “all type stretch wrapping machine | wrapping machine in India ” ..

Green Irrigation – offering Green Drip Flat Drip Irrigation Pipe at Rs 2/meter in Rajkot, Gujarat

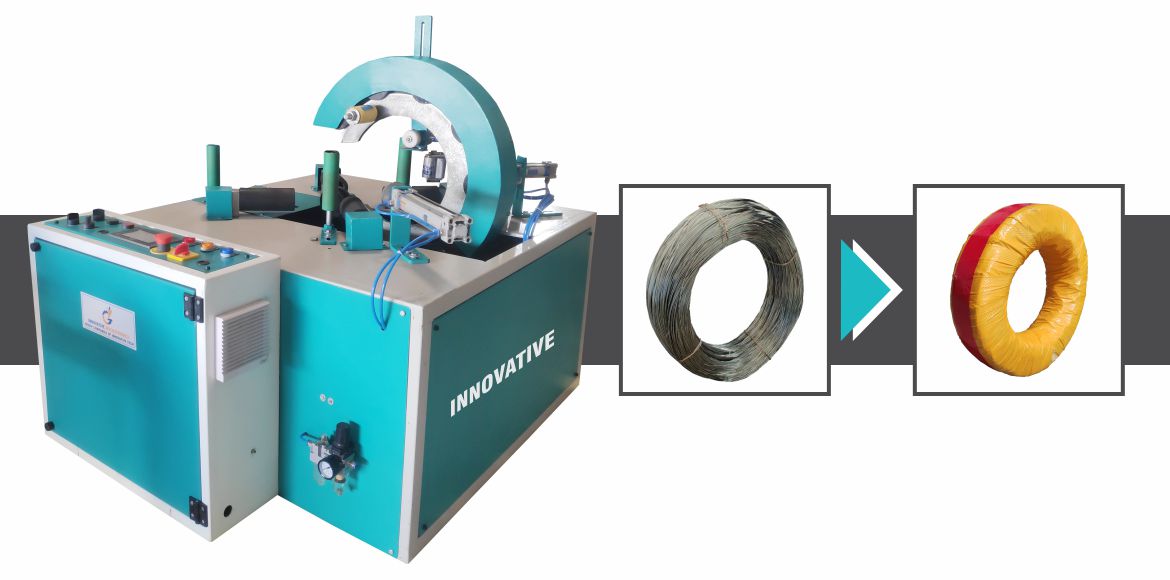

binding wire coil stretch wrapping machine innovative make.

Jan 25, 2017 Stretch Wrapping machine- Binding wire coils, Tyres, Cables, kelipacking wire,drip Irrigation pipe, tire,carton,corrugated box, flat drip,

MS Wire Coil Wrapping Machine

An MS Wire Coil Wrapping Machine is an industrial packaging system designed to wrap mild steel (MS) wire coils using stretch film or protective wrapping material. The machine secures the coil shape, protects the wire surface from moisture, dust, and corrosion, and improves handling safety during storage and transportation.

Manufacturers use this machine to achieve uniform, professional packaging while reducing manual labor and material waste.

Different Types or Variants and When Each Is Used

Semi-Automatic MS Wire Coil Wrapping Machine

This variant suits small to medium production volumes. Operators load and unload coils manually, while the machine performs the wrapping process. Buyers choose this type when flexibility and lower initial investment matter more than maximum speed.

Fully Automatic MS Wire Coil Wrapping Machine

This variant integrates conveyors, automatic film cutting, and PLC control. It fits high-volume production lines where speed, consistency, and minimal manpower are critical.

Horizontal Orbital Wrapping Machine

This design supports heavy or large-diameter MS wire coils. It provides stable coil positioning and uniform tension, making it ideal for steel wire manufacturers and export-oriented plants.

Custom Heavy-Duty Variant

This variant handles oversized or high-weight coils. Buyers select it when coil dimensions, weight, or special protection requirements exceed standard ranges.

What Are the Energy and Power Requirements of the Machine?

MS wire coil wrapping machines operate with energy-efficient electric drives designed for continuous industrial use.

Power supply: 380–415V, 3-phase, 50 Hz

Installed power: Typically 2.5 kW to 7.5 kW, depending on size and automation level

Energy consumption: Low per coil due to short wrapping cycles and optimized motor control

These machines use variable frequency drives (VFDs) and PLC systems to reduce unnecessary power usage. Buyers benefit from lower operating costs, stable performance, and improved sustainability compared to manual or heat-based packaging methods.

How Long Is the Expected Service Life of the Machine?

A professionally built MS wire coil wrapping machine offers a long service life of 10 to 15 years or more when operators follow proper maintenance practices.

Key factors that extend machine life include:

Heavy-duty steel frame construction

Industrial-grade motors, bearings, and drives

PLC-based control systems with overload protection

Regular preventive maintenance and timely part replacement

Manufacturers prefer these machines because they deliver consistent output, high uptime, and strong return on investment over many years of operation.

What is an MS wire coil wrapping machine used for?

An MS wire coil wrapping machine packages mild steel wire coils with stretch film or protective material. It secures the coil shape, prevents corrosion, and protects the wire from dust, moisture, and handling damage during storage and transport.

Which industries commonly use MS wire coil wrapping machines?

Manufacturers use these machines in wire drawing plants, steel processing units, construction material manufacturing, hardware production, and export packaging facilities.

How much power does an MS wire coil wrapping machine consume?

Most machines operate on a 3-phase 380–415V power supply and consume between 2.5 kW and 7.5 kW. Energy-efficient drives help reduce operational costs.

What packaging materials can the machine use?

The machine supports stretch film, LDPE film, HDPE film, and VCI film depending on corrosion protection and storage requirements.

How many coils can the machine wrap per hour?

Production capacity depends on coil size and automation level. Small coils typically allow 35–45 coils per hour, while larger coils allow 20–30 coils per hour.