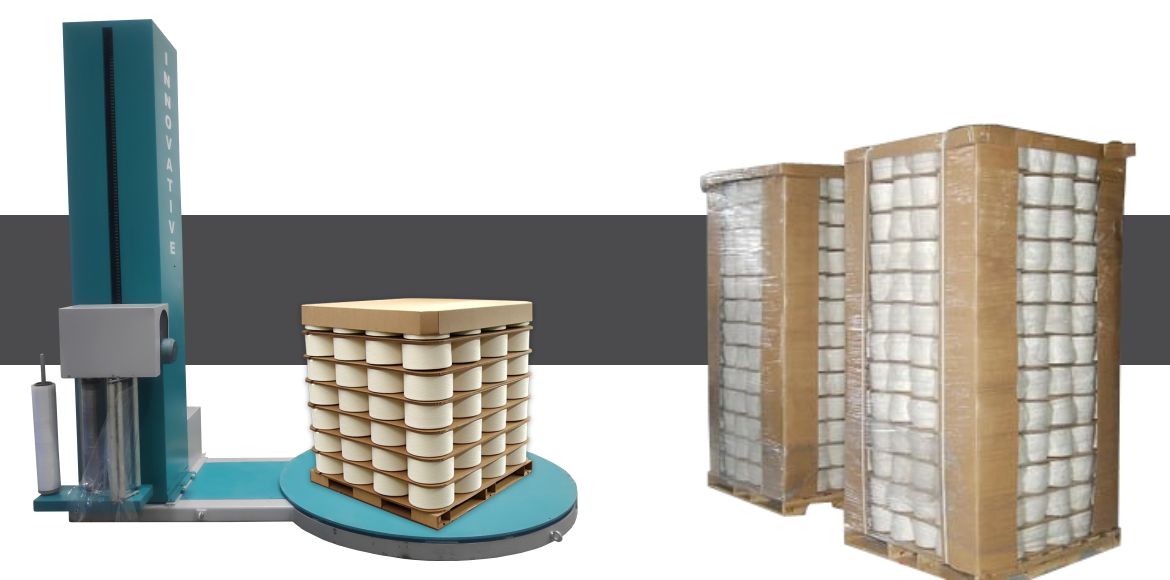

Pallet Stretch Wrapping Machine is ideal for wrapping and packaging machines with automatics and manual, it’s safe and secure for moisture and perforation. This automatic wrapping machine is packing all types of products like textile, pharma equipment, chemical materials, electronics product, and many more products as per your views.

We are manufacturers, suppliers, and exporters of automatic pallet stretch wrapping machines for yarn cotton yarn. This product is a holder with international standards, durable quality materials, and long-lasting features in Ahmedabad, India.

We are manufacturing Pallet Wrapping Machine For Cotton Yarn with the auto-scale system.

Advantages:-

- save film Upto (300 % )with Pre-stretch unit system

- save labor

- uniform packaging

- make in India pallet wrapping machine

- power pre-stretch system available

Pallet Wrapping Machine for Cotton Yarn

A Pallet Wrapping Machine for Cotton Yarn is an industrial packaging solution designed to secure cotton yarn pallets for storage, handling, and transportation. The machine ensures the yarn bales remain stable, protected from dust, moisture, and mechanical damage, while enabling efficient warehouse and logistics operations.

Modern factories rely on these machines to reduce manual labor, improve packaging consistency, and enhance operational safety.

How the Machine Works

Pallet Placement

Operators load cotton yarn bales onto a standard pallet using forklifts or pallet trucks.

Sensor-based systems detect pallet presence and height.

Pre-Operation Setup

Select wrapping program based on load type, pallet height, and stretch film specification.

Turntable or Rotary Arm Operation

The pallet rotates on a turntable or the wrapping arm moves around the load.

Film is applied uniformly from bottom to top.

Film Application & Tension Control

The machine stretches film to the set tension, stabilizing the pallet.

Optional top sheet or edge protection is applied for delicate yarn bales.

Cutting and Sealing

Automated film cutting and sealing systems secure the wrap.

Semi-automatic models require operator confirmation.

Pallet Discharge

Wrapped pallet exits the station for storage or transport.

Why This Machine Is Critical in Modern Industrial Operations

Load Stability: Prevents yarn bales from shifting or collapsing during transport.

Efficiency: Speeds up packaging, reducing handling time and labor costs.

Product Protection: Shields cotton yarn from dust, moisture, and mechanical damage.

Consistency: Provides uniform wrapping quality, essential for export-grade shipments.

Safety: Reduces workplace injuries caused by manual wrapping of heavy pallets.

Standard Industry-Level Specifications

Pallet Weight Capacity: 500–3,000 kg

Pallet Size: 800 × 1,200 mm to 1,000 × 1,200 mm

Wrapping Speed: 20–50 pallets/hour (depending on model)

Film Thickness: 20–35 microns

Power Supply: 380–415V, 3-phase

Control System: PLC with HMI touchscreen

Safety Systems: Emergency stops, safety guards, interlocks

Machine Construction: Heavy MS / structural steel

Industries and Real-World Applications

Cotton yarn export and logistics

Warehousing and distribution

Spinning mills

Industrial packaging for delicate fiber products

Frequently Asked Questions (FAQ)

1. What is the purpose of this machine?

It secures palletized cotton yarn bales with stretch film, preventing shifting, damage, and exposure during storage and transport.

2. How does it improve packaging efficiency?

The automated system wraps pallets quickly and uniformly, reducing manual labor and increasing throughput.

3. Can it handle heavy or irregular loads?

Yes. Adjustable tension control and robust turntable or rotary arm design ensure safe wrapping of uneven or heavy pallets.

4. Which industries benefit from this machine?

Textile manufacturers, spinning mills, cotton yarn exporters, warehousing, and logistics providers rely on it for consistent pallet stability.

5. How does it reduce material usage?

Pre-stretch film systems and precise tension control minimize film waste while maintaining secure wrapping.