Ropp Wire Wrapping Machine use to wrap flat drip irrigation pipe . Reel Stretch Wrapping Machine is used for stretch film wrapping around the Non-woven, coil, paper roils, rubber product and similar materials manufactured in small reels. Reel Stretch wrapping machine assist in reduction of labor by automating the process of attaching, detaching and pressing the film. For the product to be wrapped, the operator simply places the item on a turn-table and switches the machine to operate.

Reel wrapping machine With pre-stretch unit system use to wrap small paper roll , flat drip pipe, laminated roll , small width paper roll.

Main advantage of pre- stretch unit save film up-to 300 %.

PP Rope Film Wrapping Machine – Innovative WrapTech Pvt. Ltd.

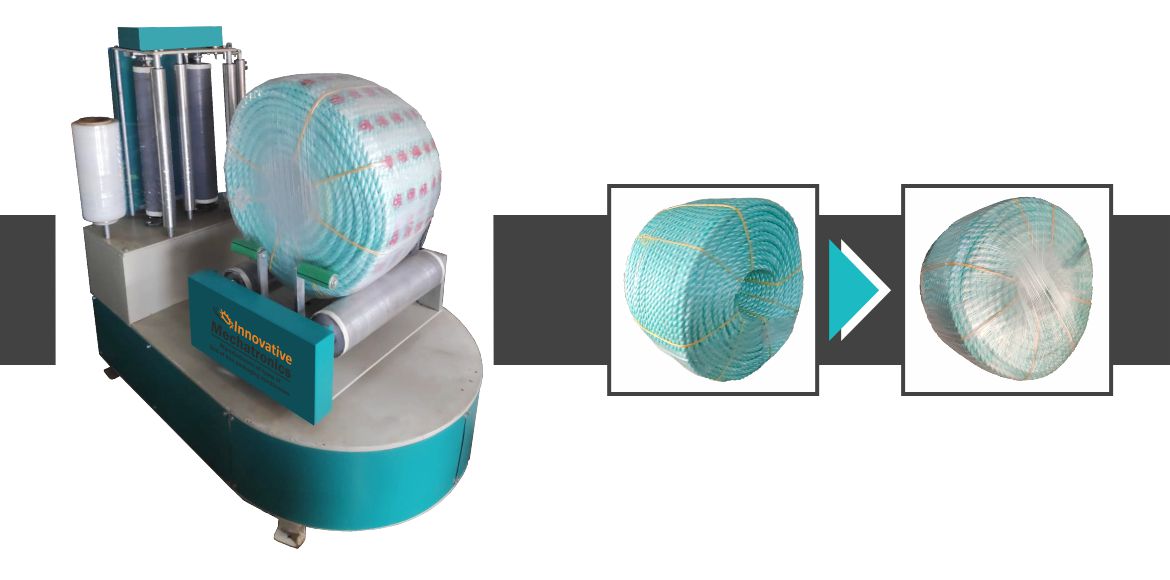

The PP Rope Film Wrapping Machine is an industrial-grade equipment designed to wrap polypropylene (PP) ropes efficiently with protective film. It securely bundles ropes for storage, handling, and transportation while maintaining consistent quality.

This machine automates the wrapping process, reduces manual labor, and ensures that each rope bundle stays intact, protected from dust, moisture, and abrasion. It caters to industries producing or distributing PP ropes, cords, and similar materials, ensuring faster throughput and professional packaging standards.

Why the PP Rope Film Wrapping Machine is Essential in Modern Industrial Operations

Boosts Productivity: Automates repetitive rope wrapping tasks, saving time and labor costs.

Maintains Consistent Quality: Controls film tension and alignment to ensure every rope bundle meets high standards.

Reduces Material Waste: Optimizes film usage and minimizes packaging costs.

Enhances Safety: Reduces manual handling, protecting operators from potential hazards.

Supports High-Volume Production: Ideal for factories that need fast, reliable, and uniform rope packaging.

Manufacturers rely on this machine to meet production deadlines, improve efficiency, and maintain a professional appearance for their products.

How to Choose the Right PP Rope Film Wrapping Machine

When selecting a PP Rope Film Wrapping Machine, consider these key factors:

Capacity: Evaluate how many rope bundles you need to wrap per hour. Choose a machine that meets current and future production needs.

Material Compatibility: Ensure the machine handles your rope diameter, length, and type of PP rope material.

Automation Level: Decide between semi-automatic or fully automatic models based on workforce availability and production goals.

Budget: Balance initial investment with long-term efficiency, reduced labor costs, and minimal maintenance.

Pro Tip: A slightly higher-capacity machine ensures scalability and avoids production bottlenecks as your business grows.

Why Manufacturers Prefer Professional-Grade Machines

Reliability: Operates continuously without frequent breakdowns.

Durability: Built with high-quality components to withstand industrial conditions.

Precision: Delivers consistent, high-quality wrapping for every rope bundle.

Low Maintenance: Reduces downtime with easy access for cleaning and lubrication.

Efficiency: Speeds up production, reduces labor dependency, and increases profitability.

Professional machines from Innovative WrapTech Pvt. Ltd. combine advanced technology, durability, and operational efficiency, making them the preferred choice for rope manufacturers.

FAQs

Q1: What types of PP ropes can this machine handle?

A: The machine wraps PP ropes of various diameters and lengths with consistent quality.

Q2: Can it handle different film types?

A: Yes, it works with multiple film types, including polyethylene (PE), providing precise tension control.

Q3: How much maintenance does it require?

A: Operators perform minimal maintenance thanks to easy access for cleaning, lubrication, and adjustments.

Q4: Is operator training necessary?

A: Operators complete basic training, and the machine’s built-in safety features make it easy to operate.

Q5: Why choose Innovative WrapTech Pvt. Ltd.?

A: Innovative WrapTech Pvt. Ltd. provides high-quality, reliable machines and offers industry-leading support to ensure smooth, efficient production.