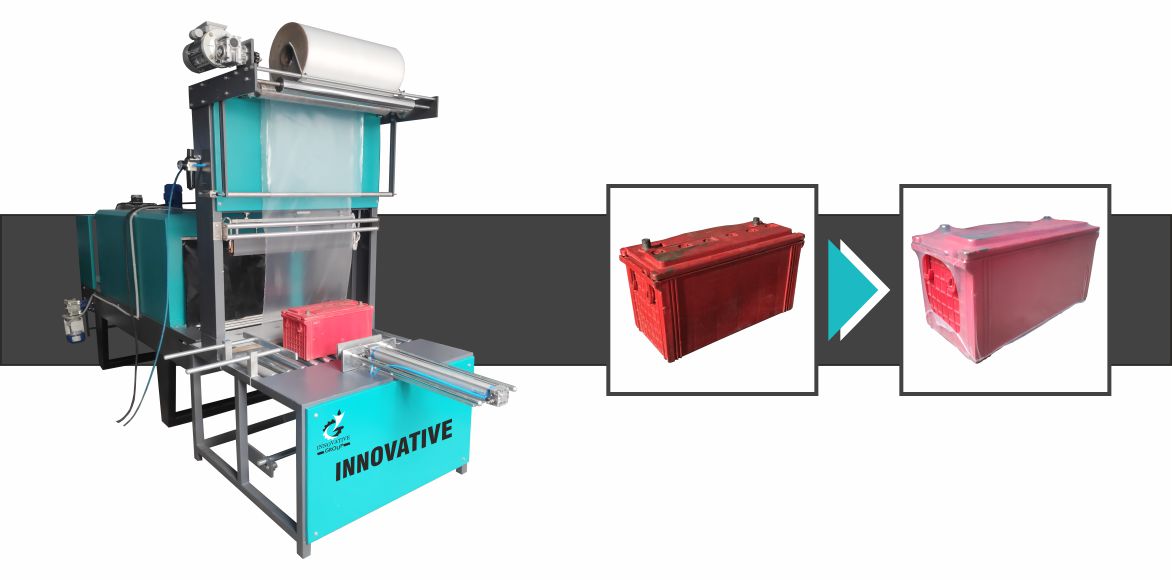

We are presenting fine quality Semi Automatic Battery Shrink Wrapping Machines with Manual Collation and with partial ‘U’ sealer. These products are developed from the best available technology.

Range:

Products such as a battery, bottles, tins, cans, boxes, containers, which are available in numerous configurations of 6, 12, 18 or 24 with/without a base tray or with the help of FLAT SHEET at the bottom, could be shrunk wrapped at various speeds of 5-15 packs per minute

stretch wrapping Similarly stretch packing After that product good looking In addition, I’m recording some video for stretch wrapping machine

Semi Automatic Battery Shrink Wrapping Machine

it is most common used machine in film heat sealing machine because of its design & economical advantage. that called Semi Automatic Battery Shrink Wrapping Machine

How Semi-automatic Battery Shrink Wrapping Machine works:-

We will understand this by taking an example of one product. If you want to wrap water bottle with semi shrink wrap then how can you do that we are explaining this step-by-step.

So, Secondly, of all you have to put 12 water bottles of 1 liter on to web sealer. Then you have to give command ‘START’. After that Automatic Air cylinders will take bottles under machine. and film is wrapped around its 3 sides automatically, then it will be sealed by one more cylinder. After this process you can see Tiles Box is wrapped around all of 4 sides and there is open space in 2 sides are visible to you.

Mainly this machine is divided into 2 parts:-

1.) Web sealer & 2.) Shrink Tunnel

When this is work in combination then whole machine is called as Inverter Battery Shrink wrapping Machine OR car Battery Group packing OR Battery shrink Bundling Machine.

Semi Automatic Battery packing Machine General Specification:-

Voltage- 3 phase 415V

Power- 2 phase

Film- 50 to 100 LDPE Shrink film

Heating Temperature- Up to 200degree C

Sealing Time- 4to 5 second

Production Capacity- 2to 7 pack/minute (depend on product size)

Semi Automatic Battery Shrink Wrap Machine Advantages:-

> Low cost

> Saves Lab our cost

> Save Power

> Save packing cost compared to Box packing machine

> Eye-catching packaging

> Easy to handle

FQA:-

1.) What is the packing cost of Tiles Box Shrink with shrink wrapping machine?

In this paragraph, It is depend upon bottle size. But we can calculate assuming 1Ltr. bottle. So, In 1Ltr. Carton Shrink film is used approx 35 to 40gm. Per kg.film price approx 135 to 150kg.

Firstly, we calculate assuming 140 Rs. In 1kg approx 23 to 25 pack will be done, and 1 Pack price is 5.5 rupees to max 6.5 rupees + 0.5 to to 0.75 electricity per packet.

Secondly, max to max it will finished in 7 to 7.25 rupees. It is vary according to film width, film micron and plastic film price.

2.) Does Semi Automatic Battery shrink wrapping work?

Yes, it is. When you heat shrink your product after wrapping around film on it then that product is sealed very tight. So, everyone knows when any product is wrapped like this

then it will be dust & moisture proof. This is only about protection but whenever we wrap our product with shrink wrapping it looks marvelous, too.

3.) What is the price of Semi Automatic Battery shrink wrapping machine?

Price is depend on different machines and which type of film is used. When any of you want to know price of the machine then we need to ask about your product. and which type

of film you want to use then according to that our R&D team will suggest you suitable machine models & price. But when we talk about price range we 40,000 to 2,00,000

rupees machine we have.