In this paragraph, many manufacturers in India but need the best quality and best price with high than purchase machines from Innovative mechatronics steel wire coil wrapper machine.

however, spiral wrapping machine mini packing machine group companies of innovative tech is one of the best companies in Indian.

innovative group however, export machines in USA, Egypt, South Africa, Kenya UAE, Australia, rasiya, Sri Lanka, Pakistan, China, Indonesia, Vietnam, Poland, France, Dubai, Canada, Brazil, Bolivia, Chile, Cyprus, Qatar, Israel.

Similarly, Innovative Group supply many more countries like

however, Uganda, United Arab Emirates, United Kingdom, Vietnam, Kingdom of Serbia, Kuwait, Spain, Philippines, Oman, Nigeria, Nepal, New Zealand, Mexico etc..

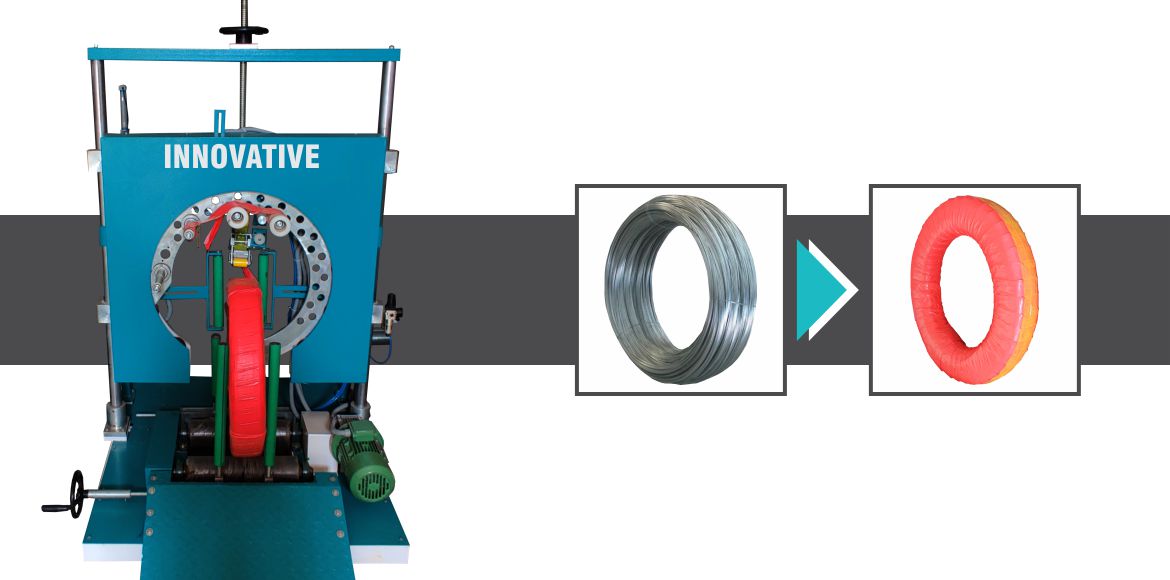

Semi Automatic Coil Wrapper

A Semi Automatic Coil Wrapper is an industrial packaging machine designed to wrap metal coils, wire coils, aluminum coils, steel strips, copper coils, and GI wire coils with stretch film, LDPE, or VCI film.

The machine automates the wrapping process while requiring manual loading and unloading, offering a cost-effective solution for consistent, secure coil packaging.

How Does a Semi Automatic Coil Wrapper Work? (Step by Step)

Coil Loading

The operator places the coil onto the turntable or cradle using a forklift or crane.Film Installation

The operator loads the stretch film roll into the film carriage and sets tension parameters.Start Command

The operator initiates the cycle through the control panel or foot switch.Coil Rotation

The machine rotates the coil at a controlled speed.Film Dispensing

The film carriage moves around or through the coil eye, applying uniform film layers.Overlap Control

The system maintains consistent overlap to ensure complete surface coverage.Film Cut and Clamp

The operator or machine cuts and secures the film at the end of the cycle.Coil Unloading

The wrapped coil exits the station, ready for storage or transport.

Why Is This Machine Important in Modern Industrial Operations?

Semi automatic coil wrappers improve packaging consistency, product protection, and workforce efficiency by:

Reducing manual labor and fatigue

Preventing moisture and corrosion damage

Standardizing wrapping quality

Increasing packaging throughput

Lowering film consumption

These machines support lean manufacturing and cost-controlled production environments.

Types and Variants of Semi Automatic Coil Wrappers

1. Vertical Semi Automatic Coil Wrapper

Best for: Eye-to-sky coil orientation

Steel and aluminum coils

High stability for heavy loads

2. Horizontal Semi Automatic Coil Wrapper

Best for: Eye-to-wall coil orientation

Wire and strip coils

Easy integration with conveyors

3. Orbital Ring Type Coil Wrapper

Best for: Uniform circumferential wrapping

Export packaging

VCI and multilayer wrapping

4. Customized Semi Automatic Coil Wrapper

Best for: Non-standard coil sizes

Heavy-duty frames

Special film materials

How Buyers Can Choose the Right Model

Capacity Requirements

Low to medium volume → Semi automatic vertical wrapper

Larger coils → Heavy-duty orbital wrapper

Material Type

GI wire and steel → Stretch film + VCI film compatibility

Aluminum or copper → Low-tension film systems

Automation Level

Manual handling acceptable → Semi automatic

High throughput required → Fully automatic upgrade

Budget Considerations

Semi automatic machines offer lower upfront investment

Automation increases long-term cost savings

Safety Standards and Operator Protection

Semi automatic coil wrappers comply with:

CE Machine Safety Standards

ISO 12100 Risk Assessment Guidelines

Emergency stop buttons

Protective guards and covers

Electrical overload protection

These safety features protect operators while maintaining smooth production flow.

Conclusion

A Semi Automatic Coil Wrapper delivers reliable, cost-effective, and safe packaging for metal coils. By selecting the correct configuration, industries achieve improved protection, reduced labor effort, and consistent packaging quality.

Frequently Asked Questions (FAQs)

Q1. What is a semi-automatic vertical coil wrapping machine used for?

A semi-automatic vertical coil wrapping machine is used to pack metal and wire coils in an upright position using stretch film or protective materials. It protects coils from moisture, dust, corrosion, and handling damage during storage and transportation.

Q2. Which types of coils can be wrapped using this machine?

The machine is suitable for steel coils, wire coils, aluminum coils, copper coils, and other round or ring-shaped products used in industrial applications.

Q3. How does a semi-automatic vertical coil wrapping machine work?

The operator places the coil vertically on the wrapping station. The machine rotates the coil while the film carriage moves around it, applying uniform tension and overlap. Film cutting and clamping are performed manually or semi-automatically.

Q4. What packaging materials can be used with this machine?

The machine supports stretch film, LDPE film, HDPE film, and VCI film depending on corrosion protection and packaging requirements.

Q5. Is this machine suitable for low to medium production volumes?

Yes, semi-automatic vertical coil wrapping machines are ideal for low to medium production volumes where flexibility, cost-effectiveness, and operator control are important.