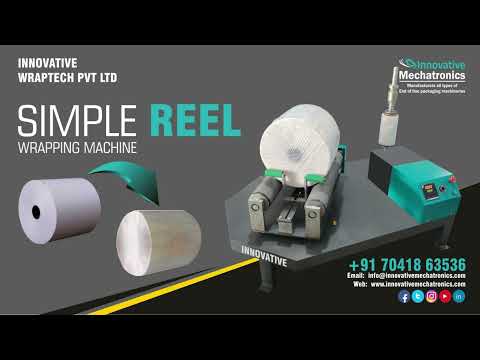

Reel Stretch Wrapping Machine. Reel Stretch Wrapping Machine is used for stretch film wrapping around the Non-woven, coil, paper roils, rubber product and similar materials manufactured in small reels.

Reel Stretch wrapping machine assists in the reduction of labor by automating the process of attaching, detaching, and pressing the film. For the product to be wrapped, the operator simply places the item on a turn-table and switches the machine to operate.

Take advantage of our widespread distribution network for getting your simple reel stretch wrapping machine.

However, the machine offered is widely recognized in various industries due to its ability to wrap the product after gluing and wrapping the film.

Small Reel Stretch Wrapper

What Is a Small Reel Stretch Wrapper?

A Small Reel Stretch Wrapper is a compact industrial packaging machine designed to securely wrap small-diameter reels such as electrical wire reels, cable coils, hoses, and lightweight industrial rolls using stretch film.

Innovative WrapTech Pvt. Ltd. designs this machine to deliver uniform tension, consistent coverage, and reliable load stability, even in limited production spaces.

Why This Machine Is Important in Modern Industrial Operations

Modern manufacturing environments demand speed, consistency, and cost control. Manual reel wrapping cannot meet these expectations.

The Small Reel Stretch Wrapper:

Protects reels from dust, moisture, and surface damage

Ensures uniform packaging quality across batches

Reduces manual handling and workplace injuries

Supports lean manufacturing and faster dispatch

For small and medium-scale factories, this machine delivers professional packaging without large-machine complexity.

How to Choose the Right Small Reel Stretch Wrapper

1. Based on Reel Capacity

Evaluate:

Minimum and maximum reel diameter

Reel width and weight

Choosing the correct capacity prevents overloading and ensures stable wrapping performance.

2. Based on Material Type

Different reels require different wrapping tension:

Electrical wire and cable reels

Plastic hose coils

Flexible industrial rolls

Select machines with adjustable film tension and wrapping programs to avoid product deformation.

3. Based on Automation Level

Semi-automatic models suit batch production and lower budgets

Fully automatic models suit continuous production lines and high throughput

Automation improves speed, consistency, and labor efficiency.

4. Based on Budget and ROI

Consider:

Initial machine cost

Stretch film savings through pre-stretch systems

Reduced labor expenses

Professional machines deliver long-term cost benefits, not just lower purchase prices.

Industries That Use Small Reel Stretch Wrappers

Electrical and cable manufacturing

Plastic pipe and hose production

Automotive wiring units

Hardware and engineering goods

Frequently Asked Questions (FAQ)

1. What products can a Small Reel Stretch Wrapper pack?

It packs small reels, cable coils, wire spools, hoses, and lightweight industrial rolls efficiently and safely.

2. How does this machine reduce labor costs?

One operator can handle the entire wrapping cycle, eliminating manual wrapping and reducing manpower requirements.

3. Is the machine suitable for small factories?

Yes. Its compact design and flexible operation make it ideal for space-constrained facilities.

4. Does the machine reduce stretch film consumption?

Yes. Controlled film tension and optional pre-stretch systems reduce film usage while maintaining load stability.

5. Is operator training required?

Basic training is sufficient. The machine features user-friendly controls and preset wrapping programs.