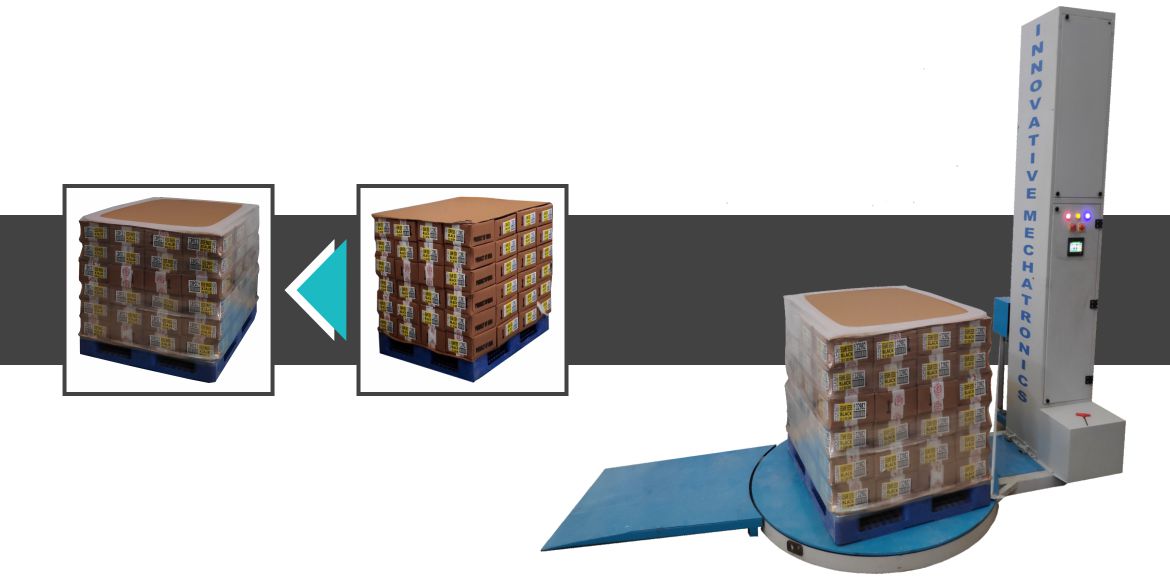

Effective presence of innovative pallet wrapping machine

Firstly, the Innovative Pallet Stretch Wrapping machine or Pallet wrapping machine is one of the best models of Innovative mechatronics,

In addition, with more than 15 years of expertise in manufacturing and exporting it.

Moreover, Different models have evolved out of the Innovative stretch wrapping machine based on customers’ specific requirements.

In conclusion, Perfection in each and every component and standardized process of manufacturing and assembly has become the order of the day.

Stretch Wrapping Machine Wrapper

A Stretch Wrapping Machine Wrapper is an industrial packaging machine that secures products—most commonly palletized loads—by wrapping them with stretch film under controlled tension. The machine rotates the load or the film carriage to apply multiple layers of stretch film, creating a tight, stable, and protective wrap.

Manufacturers and logistics operators use this machine to protect goods from movement, dust, moisture, and transit damage while improving packaging speed and consistency.

How Does a Stretch Wrapping Machine Wrapper Work? (Step by Step)

The operator places the pallet or product on the turntable or conveyor.

The operator attaches the stretch film to the load.

The machine starts the wrapping cycle through the control panel.

The turntable or wrapping arm rotates while the film carriage moves vertically.

The machine applies controlled tension and film overlap.

The wrapper completes top and bottom reinforcement wraps.

The machine cuts or seals the film at the end of the cycle.

The operator removes the securely wrapped load.

This process delivers uniform wrapping quality with minimal film waste.

Why Is This Machine Important in Modern Industrial Operations?

Modern supply chains demand speed, reliability, and load safety. Manual wrapping cannot deliver consistent results at high volumes.

A Stretch Wrapping Machine Wrapper:

Reduces product damage and returns

Increases packaging speed and throughput

Lowers stretch film consumption

Reduces labor fatigue and injury risk

Supports standardized and export-ready packaging

Industries rely on this machine to maintain operational efficiency and packaging quality.

Types and Variants of Stretch Wrapping Machine Wrapper

1. Manual Stretch Wrapper

Use this for very low-volume operations or temporary packaging needs.

2. Semi-Automatic Stretch Wrapping Machine

Use this when operators load pallets manually but require consistent wrapping quality.

3. Fully Automatic Stretch Wrapping Machine

Use this for high-speed production lines with conveyors and minimal human intervention.

4. Rotary Arm Stretch Wrapper

Use this for unstable or lightweight loads that cannot rotate.

5. Mobile Stretch Wrapping Machine

Use this for oversized or heavy loads that cannot move to a fixed station.

How Buyers Can Choose the Right Model

Capacity

Match the machine speed to daily pallet volume.

Material Type

Choose tension control suitable for fragile or heavy loads.

Automation Level

Select semi-automatic for moderate volumes and fully automatic for continuous production.

Budget

Evaluate total cost of ownership, not just purchase price.

Conclusion

A Stretch Wrapping Machine Wrapper is a critical asset in modern industrial packaging. It improves efficiency, reduces costs, enhances safety, and ensures consistent load protection across supply chains.

(FAQ)

1. What is a Stretch Wrapping Machine Wrapper?

A Stretch Wrapping Machine Wrapper is an industrial packaging machine that secures palletized or unitized loads using stretch film under controlled tension to improve load stability and protection.

2. How does a stretch wrapping machine wrapper work?

The machine rotates the load or wrapping arm while applying stretch film with controlled tension and overlap, creating a tight and uniform wrap around the product.

3. Why is a stretch wrapping machine important in industrial packaging?

The machine improves packaging speed, reduces product damage, lowers film consumption, enhances worker safety, and ensures consistent packaging quality across operations.

4. Which products can be wrapped using this machine?

The machine wraps cartons, boxes, drums, bags, pails, FMCG products, chemicals, food items, pharmaceuticals, and industrial components on pallets.

5. What types of stretch wrapping machine wrappers are available?

Common types include manual, semi-automatic, fully automatic, rotary arm, mobile, and conveyor-integrated stretch wrapping machines.