Unwrapping the ROI: How Data Analytics Optimize Your Automated Pallet Wrapping System

How Data Analytics Improve ROI in Automated Pallet Wrapping Systems

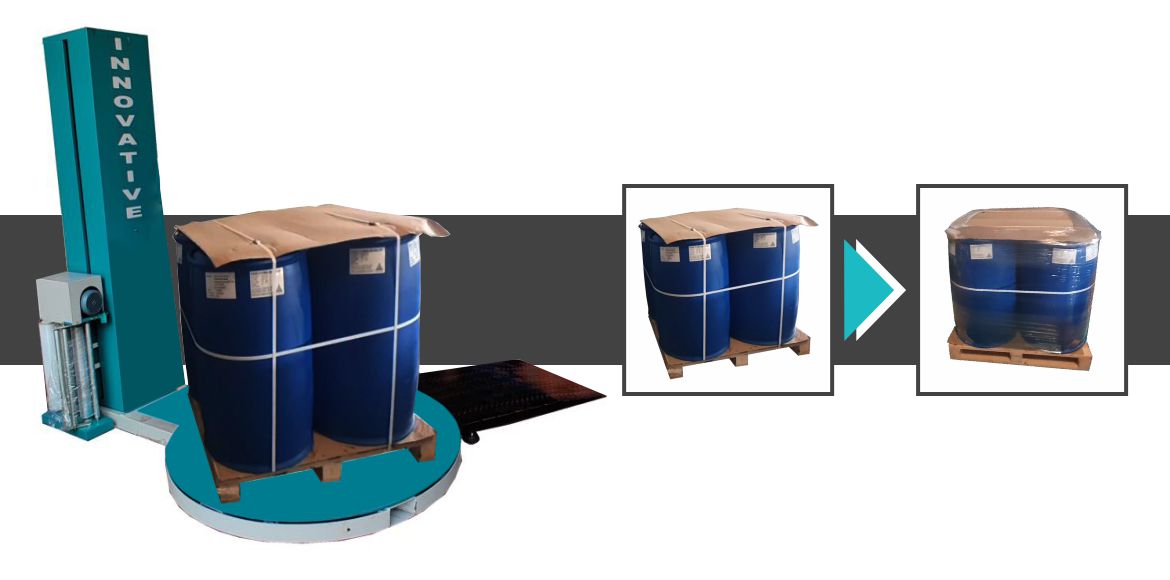

Automated pallet wrapping no longer operates as a mechanical process alone. In modern manufacturing and logistics, data analytics transforms pallet wrapping into a measurable, controllable, and continuously improving operation. At Innovative WrapTech Pvt. Ltd., we design automated pallet wrapping systems that use real-time data to reduce material waste, increase uptime, and deliver predictable return on investment.

This guide explains how data-driven pallet wrapping works, why it matters, and how manufacturers can evaluate, operate, and justify these systems financially.

What Is a Data-Enabled Automated Pallet Wrapping System?

A data-enabled automated pallet wrapping system combines mechanical wrapping equipment, sensors, controllers, and analytics software. The system collects operational data during every wrap cycle and converts it into actionable insights.

These machines measure:

Film consumption

Wrap tension and consistency

Cycle time and throughput

Equipment health and usage patterns

Instead of guessing performance, operators and managers rely on data.

How Data-Driven Automated Pallet Wrapping Works

Step 1: Load Identification

Sensors detect pallet height, weight, and stability before wrapping begins.

Step 2: Wrap Program Optimization

The controller selects or adjusts wrap recipes based on historical performance and load type.

Step 3: Real-Time Wrapping Execution

During wrapping, the system monitors film tension, pre-stretch ratio, and rotation speed continuously.

Step 4: Data Capture and Logging

Each cycle generates data stored locally or transmitted to a central dashboard or cloud platform.

Step 5: Analysis and Optimization

The system identifies trends such as excess film usage or early signs of component wear.

Why Data Analytics Is Critical in Modern Industrial Operations

Traditional pallet wrapping lacks visibility. Without data:

Film waste goes unnoticed

Downtime becomes reactive

Performance varies by operator

Data analytics delivers:

Up to 50% reduction in stretch film consumption

Consistent packaging quality

Faster root-cause analysis

Measurable performance improvement

Types of Data-Enabled Automated Pallet Wrapping Systems

1. Turntable-Based Automated Wrappers

Best for standard pallet loads in medium-volume operations.

2. Rotary Arm Wrappers

Used for unstable or lightweight loads where the pallet remains stationary.

3. Ring-Type High-Speed Wrappers

Designed for high-throughput production lines with continuous flow.

4. Inline Conveyorized Systems

Integrated directly into automated production and logistics lines.

Key Technical Features and Measurable Benefits

| Data Feature | Operational Benefit |

|---|---|

| Film usage analytics | Reduced material cost |

| Load stability monitoring | Lower transit damage |

| Cycle time tracking | Higher throughput |

| Motor and drive diagnostics | Reduced downtime |

| Dashboard visualization | Improved decision-making |

Standard Industry-Level Technical Specifications

Wrapping speed: 30–120 pallets/hour

Pre-stretch ratio: Up to 300%

Load height sensing: Ultrasonic or laser

Connectivity: Ethernet, Wi-Fi, optional cloud access

Power supply: 415V / 3 Phase

Installation, Operation, and Maintenance Best Practices

Installation Best Practices

Verify network and power availability

Calibrate sensors correctly

Secure machine anchoring for accuracy

Daily Operation

Review dashboard alerts

Inspect film rolls and carriage movement

Validate wrap consistency visually

Maintenance Routines

Daily: Clean sensors and rollers

Weekly: Inspect belts, drives, and data connections

Long-Term: Analyze trend reports and schedule predictive maintenance

Why Manufacturers Choose Professional-Grade Machines

Low-cost machines lack:

Reliable sensors

Data accuracy

Compliance support

Professional-grade systems deliver:

Accurate analytics

Stable mechanical performance

Predictable lifecycle costs

Higher operational confidence

Future Trends and Smart Factory Integration

Data-driven pallet wrapping evolves through:

AI-based wrap optimization

Predictive maintenance models

Seamless ERP and WMS integration

Remote monitoring and diagnostics

These trends position pallet wrapping as a core element of smart factory ecosystems.

Data analytics turns automated pallet wrapping into a measurable profit center rather than a packaging expense. Manufacturers that adopt data-enabled systems gain control over costs, uptime, and quality.

If your operation values predictable ROI, operational transparency, and scalable automation, a data-driven pallet wrapping system from Innovative WrapTech Pvt. Ltd. is a strategic investment.

Q1. How does data analytics improve ROI in automated pallet wrapping systems?

Data analytics improves ROI by monitoring film usage, wrap cycles, downtime, and load stability. This data helps reduce material waste, optimize machine settings, and lower operational costs.

Q2. What performance data can be tracked in an automated pallet wrapper?

Automated pallet wrapping systems track film consumption, pre-stretch ratio, cycle time, pallet count, machine uptime, fault logs, and energy usage for continuous performance improvement.

Q3. Can data analytics reduce stretch film consumption?

Yes. By optimizing wrap patterns and pre-stretch settings based on real data, manufacturers can reduce stretch film usage by up to 30–40% compared to manual wrapping.

Q4. How does analytics support preventive maintenance?

Analytics identifies wear patterns, fault trends, and load stress, enabling predictive maintenance that minimizes unexpected breakdowns and extends machine lifespan.

Q5. What is the typical ROI timeline for an automated pallet wrapping system?

Most manufacturers achieve ROI within 6–18 months through labor savings, reduced film usage, lower product damage, and improved productivity.