What To Expect After Purchasing A Packaging Machine

Guide to Packaging Machine Purchase Expectations

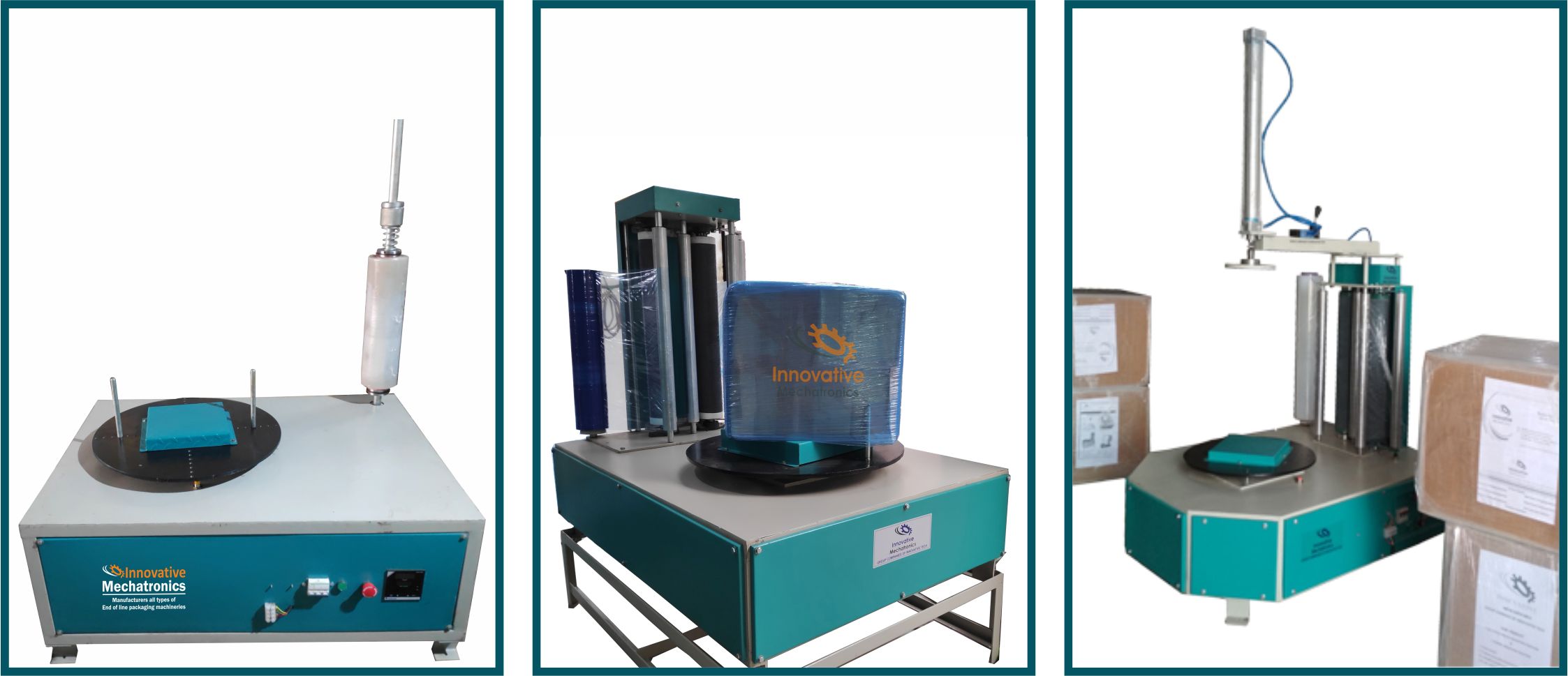

Investing in a packaging machine is a significant decision for any business. Understanding packaging machine purchase expectations ensures that your investment delivers the maximum value and efficiency from day one. Many businesses make the mistake of focusing only on cost and features, ignoring what to expect after the purchase. This guide helps you navigate installation, operation, maintenance, and ROI for a smooth post-purchase experience.

What to Expect After Buying a Packaging Machine

Once you finalize your purchase, your business will enter the post-purchase phase, where expectations matter the most. Companies should anticipate:

Installation Requirements: Machines often require proper flooring, electrical supply, and enough clearance space for safe operation.

Operator Training: Employees must learn safe handling, start-up procedures, emergency stops, and routine maintenance.

Initial Test Runs: Manufacturers usually recommend test runs with sample products to ensure calibration and wrapping or filling accuracy.

Integration With Existing Systems: Many packaging machines can connect to conveyors, ERP, or warehouse management systems. Proper integration ensures smooth operations.

Installation and Setup Expectations

The installation of a packaging machine is a critical first step in meeting packaging machine purchase expectations. Proper setup ensures your machine operates at peak performance and reduces downtime. Key aspects include:

Leveling and Anchoring: Ensure the machine is stable to prevent vibration during operation.

Electrical and Safety Checks: Verify power supply, grounding, and emergency stop mechanisms.

Calibration: Adjust machine settings based on product size, packaging material, and speed requirements.

Trial Runs: Conduct test runs to identify potential issues before full-scale operation.

Proper installation sets the stage for efficient operation, reduces long-term maintenance needs, and aligns with the initial expectations from your purchase.

Operation and Performance Expectations

Once the machine is installed, understanding its operational capabilities is crucial. Businesses should expect:

Consistent Output: Professional machines deliver uniform packaging quality and minimal product damage.

Operator Efficiency: Semi-automatic or automatic machines reduce manual labor, allowing staff to focus on higher-value tasks.

Speed and Throughput: Expect increased production rates, especially with fully automatic machines.

Flexibility: Many modern machines accommodate different packaging types and product sizes, ensuring adaptability as your business grows.

Meeting these operational benchmarks is a key part of fulfilling packaging machine purchase expectations.

Maintenance and Longevity Expectations

Maintenance is an essential part of your packaging machine purchase expectations. A well-maintained machine will last longer and reduce downtime. Best practices include:

Daily Checks: Inspect belts, rollers, sensors, and clean the machine.

Weekly Maintenance: Lubricate moving parts, check electrical connections, and ensure tension mechanisms function properly.

Long-Term Care: Replace worn components, calibrate sensors, and schedule preventive maintenance to avoid unexpected breakdowns.

Adhering to these maintenance routines ensures optimal performance and protects your investment.

ROI and Cost Expectations

Understanding financial outcomes is a crucial part of packaging machine purchase expectations. Buyers should expect:

Labor Savings: Reduced manual handling increases productivity.

Material Efficiency: Precision mechanisms minimize film, carton, or filler waste.

Fewer Product Damages: Proper wrapping or sealing reduces loss from damaged goods.

Faster Production Cycles: Automated operations increase throughput, improving profitability.

Professional-grade machines may cost more initially, but they usually pay for themselves through efficiency gains and long-term savings.

Future Trends and Automation

Modern packaging machines are evolving to meet Industry 4.0 and smart factory demands. Businesses can expect:

IoT-enabled monitoring for predictive maintenance

Integration with automated storage and conveyor systems

Energy-efficient motors and sustainable packaging options

AI-driven optimization for packaging patterns and material usage

These trends ensure that your machine remains competitive and scalable for future business needs.

Meeting packaging machine purchase expectations requires careful planning, proper installation, operator training, and adherence to maintenance routines. Businesses that plan for these factors benefit from consistent output, reduced costs, improved efficiency, and long-term ROI. By understanding what to expect after purchase, you can maximize your investment and avoid common pitfalls that affect performance and reliability.

FAQs

1. What should I expect immediately after purchasing a packaging machine?

Expect installation requirements, operator training, test runs, and system integration to ensure smooth operation.

2. How often should I maintain my packaging machine?

Daily checks, weekly lubrication and inspections, and long-term preventive maintenance are recommended.

3. Will a packaging machine reduce labor costs?

Yes, automated or semi-automatic machines reduce manual handling, freeing staff for higher-value tasks.

4. Can a packaging machine handle different product types?

Most modern machines are versatile and can adjust to different sizes, shapes, and packaging materials.

5. How soon can I expect ROI from a packaging machine?

ROI typically occurs within 12–24 months, depending on production volume, labor savings, and reduced material waste.