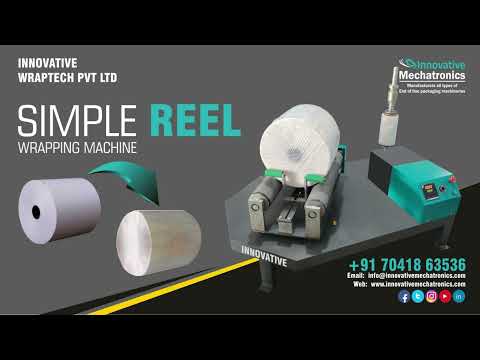

Manual Reel Wrapper is used for stretch film wrapping around the Non-woven, coil, paper roils, rubber product and similar materials manufactured in small reels.

Reel Stretch wrapping machine assists in the reduction of labor by automating the process of attaching, detaching, and pressing the film. For the product to be wrapped, the operator simply places the item on a turn-table and switches the machine to operate.

Take advantage of our widespread distribution network for getting your simple reel stretch wrapping machine.

However, the machine offered is widely recognized in various industries due to its ability to wrap the product after gluing and wrapping the film.

Manual Reel Wrapper

A Manual Reel Wrapper is a compact industrial packaging machine designed to wrap reels, coils, rolls, and cylindrical products using stretch film with manual or semi-assisted operation. The operator controls reel rotation and film application to create a tight, secure wrap that protects the product from dust, moisture, and handling damage.

Innovative WrapTech Pvt. Ltd. designs manual reel wrappers for small to medium production units that require reliable packaging without high automation investment.

Why Is This Machine Important in Modern Industrial Operations?

Many industries handle reels and coils in low to medium volumes where full automation is unnecessary. Manual wrapping creates inconsistent tension and exposes operators to injury.

A Manual Reel Wrapper:

Improves wrapping consistency compared to hand wrapping

Protects reels from dust, moisture, and surface damage

Enhances workplace safety around sharp or heavy reels

Lowers packaging costs for small-scale operations

This machine offers a practical balance between efficiency and affordability.

How to Choose the Right Manual Reel Wrapper

1. Based on Capacity

Select a machine that matches your workload:

Low-volume operations: Basic manual reel wrappers

Medium-volume operations: Manual wrappers with assisted rotation

Choosing the right capacity prevents operator fatigue and delays.

2. Based on Reel Material

Different reel materials require different handling:

Steel and GI coils: Strong frame and stable base

Aluminum reels: Smooth rotation with controlled tension

Paper or plastic reels: Gentle wrapping to avoid deformation

Innovative WrapTech machines support multiple reel types.

3. Based on Automation Level

Fully Manual: Operator controls all movement and wrapping

Semi-Assisted Manual: Mechanical aids improve speed and consistency

Even limited automation improves safety and wrap quality.

4. Based on Budget

Manual reel wrappers offer:

Low initial investment

Minimal maintenance costs

Reduced film wastage compared to hand wrapping

They deliver excellent ROI for small manufacturers and workshops.

Why Manufacturers Prefer Professional-Grade Machines

Manufacturers choose Innovative WrapTech Pvt. Ltd. because professional-grade manual machines provide:

Reliable and repeatable wrapping results

Custom options for reel diameter and width

Lower downtime compared to improvised solutions

Strong after-sales support

Professional machines ensure consistent quality even with manual operation.

Frequently Asked Questions (FAQ)

1. What products can a manual reel wrapper handle?

The machine wraps steel coils, wire reels, paper rolls, plastic reels, and similar cylindrical products.

2. Is a manual reel wrapper better than hand wrapping?

Yes. It improves consistency, reduces physical effort, and enhances safety.

3. Does the machine require electricity?

Some models are fully manual, while others use minimal power for assisted rotation.

4. Is this machine suitable for export packaging?

It provides basic protection suitable for domestic and short-distance transport.

5. Can the machine handle different reel sizes?

Yes. Innovative WrapTech Pvt. Ltd. offers adjustable and customized designs.