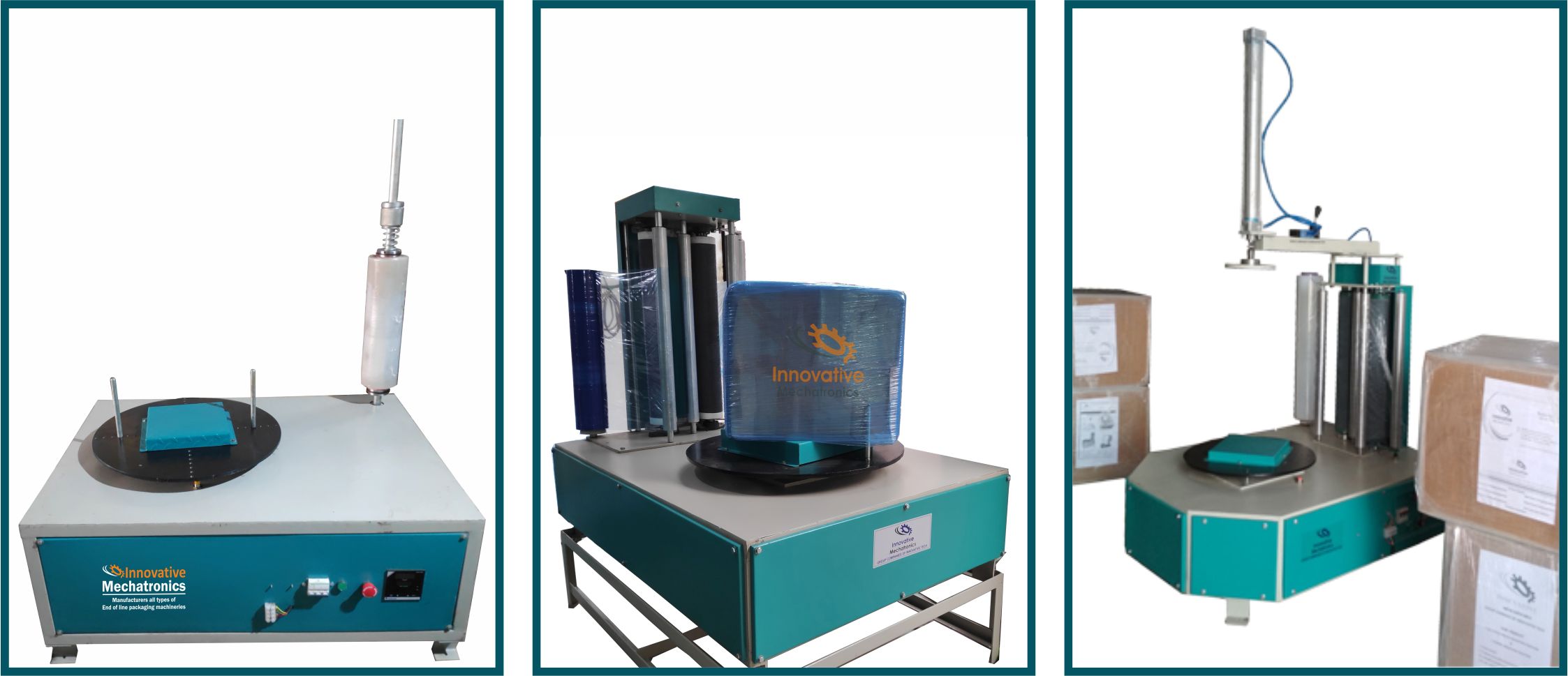

Box Strapping Machine Copper Heater Cable is very easy to operate for operators. Box Stretch Wrapping Machine with Pneumatic Holder also gives optional Pneumatic Holder feature availability also include Optional Film power stretching feature availability.

The Box stretch wrapping machine now widely used in different industries like Pharmaceuticals, Electrical and Electronics Components, Engineering Items, Sweet Box Packing, Airport Box Wrapping Machine Further include Cosmetics and Consumer goods, etc.

Advantages Of Box Wrapping Machine:-

There are certain advantages you can find with the use of Box stretch wrapping machine:-

1.) Box Wrapping Machine Provides protection from moisture & foreign Particles.

2.) Protection from Pilferage/ Tamper.

3.)Protects damage to carton during transit.

4.)The cartons remain free from dust.

Box Wrapping Machine Storage

A Box Wrapping Machine Storage system wraps cartons and boxed products with stretch or shrink film to protect them during storage and transportation. Manufacturers use this machine to stabilize loads, prevent dust and moisture ingress, and reduce product damage in warehouses and logistics environments.

Step-by-Step Technical Working Process

Box Placement – Operators place single boxes or stacked cartons on the wrapping platform or conveyor.

Film Engagement – The film carriage applies controlled tension to stretch or shrink film.

Rotational or Orbital Wrapping – The machine rotates the load or moves the film arm around the box to ensure full coverage.

Layer Control – Sensors manage overlap, wrap count, and tension for uniform protection.

Film Cut & Seal – The system cuts and seals the film automatically or semi-automatically.

Discharge – Wrapped boxes move to storage racks or dispatch zones.

This controlled process ensures consistent packaging quality across every shift.

Why This Machine Is Important in Modern Industrial Operations

Modern industries demand damage-free storage, faster dispatch, and consistent packaging quality. A Box Wrapping Machine Storage system delivers all three.

Key Industrial Advantages

Prevents carton collapse during stacking

Protects goods from dust, moisture, and handling damage

Reduces labor dependency and manual wrapping errors

Ensures uniform presentation for export and logistics

In high-volume warehouses, manual wrapping cannot maintain consistency or safety standards.

How to Choose the Right Box Wrapping Machine Storage

Selecting the right machine depends on operational needs and long-term cost efficiency.

1. Capacity Requirements

Low volume: Semi-automatic models

Medium to high volume: Fully automatic or conveyor-integrated systems

2. Box Size and Material

Corrugated cartons

Paperboard boxes

Multi-pack boxed products

Ensure the machine supports variable box dimensions and load weights.

3. Automation Level

Manual: Operator-controlled wrapping

Semi-automatic: Reduced labor, better consistency

Fully automatic: Continuous production with minimal intervention

4. Budget and ROI

Professional machines cost more initially but reduce film wastage, labor costs, and product damage over time.

Safety Standards, Compliance, and Operator Protection

Innovative WrapTech Pvt. Ltd. designs machines that meet international industrial safety norms.

Common Safety Features

Emergency stop buttons

Safety guards and covers

Overload protection systems

Electrical safety interlocks

Controlled film tension to avoid snapping

Compliance Standards

CE guidelines

ISO manufacturing practices

Electrical safety standards (IEC compliant)

These features protect operators while maintaining production efficiency.

Why Manufacturers Prefer Professional-Grade Machines

Manufacturers choose professional-grade machines because they deliver long-term reliability and operational stability.

Key Reasons

Higher wrapping consistency

Lower film consumption

Stronger load stability

Better integration with warehouse systems

A professional Box Wrapping Machine Storage solution supports growth without frequent upgrades.

Conclusion

A Box Wrapping Machine Storage system from Innovative WrapTech Pvt. Ltd. offers a reliable, safe, and cost-effective solution for modern storage and transport packaging. It enhances protection, improves efficiency, and supports scalable industrial operations.

Frequently Asked Questions (FAQ)

1. What are the energy and power requirements of the machine?

Most box wrapping machines operate on single-phase or three-phase power, depending on automation level. Typical consumption ranges from 1.2 kW to 3 kW, making them energy-efficient for continuous use.

2. Can this machine handle different box sizes?

Yes. Adjustable guides and programmable settings allow quick size changes.

3. Is operator training required?

Basic training ensures optimal performance and safe operation. The learning curve is minimal.

4. Does the machine support warehouse automation?

Yes. Fully automatic models integrate easily with conveyors and storage systems.

5. How often does maintenance need to be performed?

Routine inspection, lubrication, and film system checks ensure long service life and stable output.