The Sensor Revolution: Achieving Unprecedented Quality Control in Bottle Wrapping

Why Bottle Wrapping Quality Control Matters More Than Ever

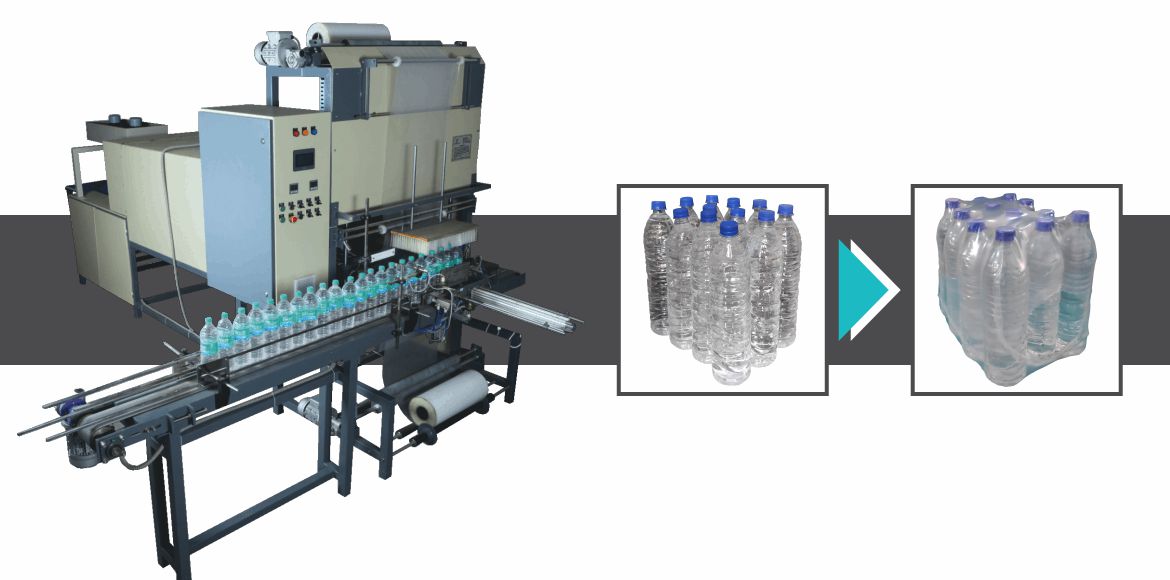

In today’s high-speed manufacturing environment, bottle wrapping quality control is no longer optional—it is critical. Industries such as beverages, pharmaceuticals, cosmetics, and chemicals depend on perfectly wrapped bottles to prevent damage, leakage, contamination, and brand loss.

Traditional wrapping methods relied heavily on manual inspection and mechanical settings, which often led to inconsistent results. Now, the sensor revolution in bottle wrapping machines is transforming quality control by delivering accuracy, consistency, and real-time intelligence.

This blog explores how sensor technology is redefining bottle wrapping, the key sensors involved, and why this innovation is essential for modern packaging operations.

What Is the Sensor Revolution in Bottle Wrapping?

The sensor revolution refers to the integration of smart sensors, automation, and data-driven controls into bottle wrapping machines. These sensors continuously monitor the wrapping process and automatically adjust machine parameters to ensure uniform wrapping quality on every bottle.

Instead of reacting to defects after they occur, sensor-enabled systems prevent errors before they happen.

Why Traditional Bottle Wrapping Faces Quality Challenges

Before sensors, bottle wrapping machines faced several limitations:

Inconsistent film tension

Uneven overlap and coverage

Bottle deformation due to excess pressure

Film wastage

Human inspection errors

High rejection and rework rates

These issues directly impact product safety, logistics efficiency, and brand reputation.

How Sensors Achieve Unprecedented Quality Control

1. Tension Sensors for Perfect Film Control

Tension sensors monitor stretch film force in real time.

They ensure that:

Bottles are wrapped tightly but not crushed

Film stretch remains consistent

Load stability improves during transport

Result: Zero bottle deformation and optimal film usage.

2. Proximity and Presence Sensors for Accurate Positioning

These sensors detect:

Bottle presence

Correct alignment on conveyors

Gaps or missing bottles

The machine automatically stops or adjusts if positioning errors occur.

Result: No missed wraps and no damaged packaging.

3. Load & Weight Sensors for Intelligent Wrapping

Weight sensors analyze the load characteristics of grouped bottles.

Based on the load, the machine:

Adjusts wrapping speed

Modifies overlap percentage

Changes film layers

Result: Customized wrapping for every bottle configuration.

4. Optical Sensors for Visual Quality Inspection

Optical sensors check:

Film transparency and coverage

Wrapping uniformity

Tears or film breakage

If defects appear, the system alerts operators instantly.

Result: Real-time defect detection with zero manual inspection.

5. Speed Sensors for Process Synchronization

Speed sensors synchronize:

Conveyor movement

Film carriage rotation

Bottle flow rate

This eliminates jerks and miswraps during high-speed operations.

Result: Smooth, high-output wrapping without errors.

Key Benefits of Sensor-Based Bottle Wrapping Machines

✔ Consistent Wrapping Quality

Sensors eliminate human variability and maintain uniform wrap tension and coverage.

✔ Reduced Film Consumption

Precision control reduces film waste by 20–40%, lowering packaging costs.

✔ Higher Production Efficiency

Machines run faster with fewer stoppages and minimal rework.

✔ Improved Product Safety

Proper wrapping prevents bottle breakage, leakage, and contamination.

✔ Real-Time Monitoring & Alerts

Operators receive instant alerts for faults, reducing downtime.

Industries Benefiting from Sensor-Driven Bottle Wrapping

Sensor-enabled bottle wrapping machines are widely used in:

Beverage & bottled water plants

Pharmaceutical manufacturing

Cosmetics & personal care

Chemical & lubricant packaging

Food & edible oil industries

Each industry benefits from higher quality standards and compliance readiness.

Integration with Industry 4.0 and Smart Factories

Modern sensor-based bottle wrapping machines seamlessly integrate with:

PLC & HMI systems

ERP & MES software

Data analytics platforms

This enables predictive maintenance, production analytics, and remote diagnostics.

Why Sensor Technology Is the Future of Bottle Wrapping

The future of packaging demands:

Zero-defect output

Cost optimization

Sustainability

Automation-ready infrastructure

Sensor-driven bottle wrapping machines meet all these demands while ensuring scalability and long-term ROI.

From Manual Control to Intelligent Precision

The sensor revolution has transformed bottle wrapping from a mechanical task into an intelligent process. By enabling real-time monitoring, automatic adjustments, and predictive control, sensors deliver unprecedented quality control that modern industries require.

Frequently Asked Questions (FAQ)

Q1. Why is quality control important in bottle wrapping?

Quality control in bottle wrapping ensures load stability, prevents bottle damage, avoids leakage, and maintains packaging consistency during storage and transportation. It also reduces product returns and brand reputation risks.

Q2. How do sensors improve bottle wrapping quality control?

Sensors monitor film tension, bottle position, load weight, and wrapping consistency in real time. They automatically adjust machine settings to eliminate defects and ensure uniform wrapping on every bottle.

Q3. What types of sensors are used in bottle wrapping machines?

Common sensors include tension sensors, proximity sensors, optical sensors, weight sensors, and speed sensors. Each sensor plays a role in improving wrapping accuracy, efficiency, and safety.

Q4. Does sensor-based bottle wrapping reduce packaging costs?

Yes. Sensor-controlled wrapping reduces stretch film wastage by 20–40%, minimizes rework, lowers downtime, and improves overall operational efficiency, resulting in significant cost savings.

Q5. Which industries benefit most from advanced bottle wrapping quality control?

Industries such as beverages, pharmaceuticals, cosmetics, chemicals, edible oils, and bottled water benefit the most due to strict safety, hygiene, and transportation requirements.