From Chaos to Containment: Banishing Pallet Wrap Nightmares with Precision Settings

From Chaos to Containment: Banishing Pallet Wrap Nightmares with Precision Settings

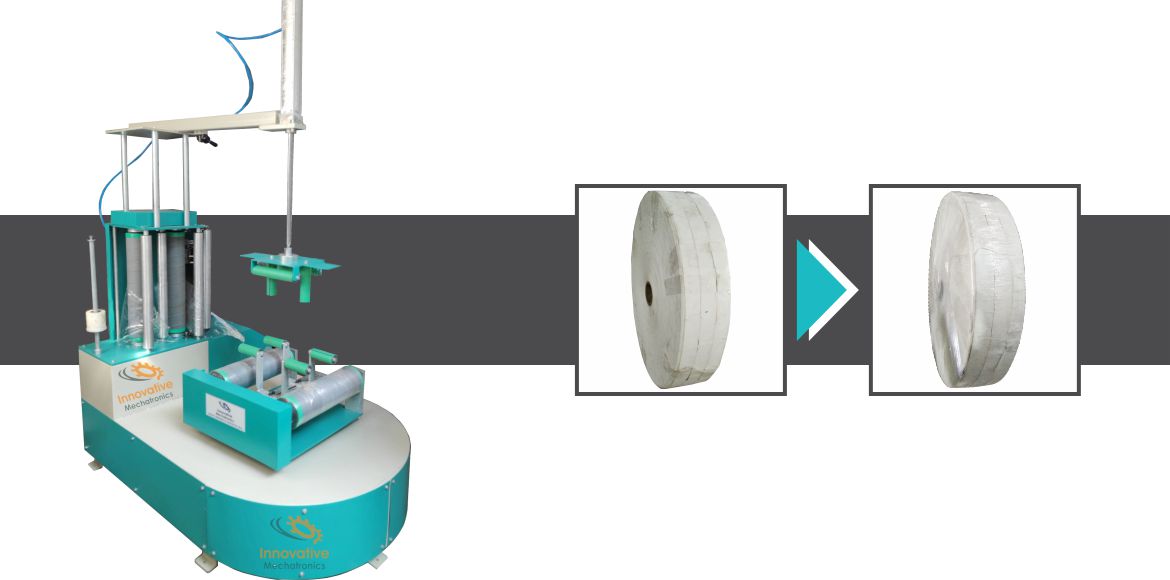

allet wrap precision settings are controlled machine parameters that regulate how stretch film is applied around a pallet load. These settings manage film tension, pre-stretch ratio, wrap speed, overlap, and number of wraps to ensure consistent, secure, and damage-free load containment.

Modern pallet wrapping machines use precision settings to eliminate guesswork and deliver repeatable, high-quality wrapping results across different products and industries.

How Do Pallet Wrap Precision Settings Work?

Load Detection

The operator places the pallet on the turntable or conveyor. Sensors detect load height and position.Film Pre-Stretch Activation

The machine stretches the film to a predefined ratio to maximize strength and minimize film usage.Tension Control Application

The system applies controlled tension based on load weight, stability, and material type.Wrap Pattern Execution

The machine follows programmed wrap cycles, including bottom wraps, body wraps, and top reinforcement.Precision Cut and Seal

The machine cuts and secures the film, ensuring a clean and consistent finish.

hy Is This Machine Important in Modern Industrial Operations?

Pallet wrap precision settings improve operational efficiency, load safety, and cost control. Industries rely on them to:

Prevent pallet collapse during transport

Reduce film waste

Support high-speed, automated workflows

These machines enable scalable, standardized packaging across large production volumes.

Standard Industry-Level Technical Specifications

Turntable Diameter: 1500–2200 mm

Load Capacity: Up to 2000–3000 kg

Film Width: 500 mm standard

Pre-Stretch Ratio: Up to 300%

Power Supply: 415V / 50Hz / 3 Phase

Control System: PLC with HMI

Industries and Real-World Applications

Logistics and Warehousing

FMCG and Food Processing

Pharmaceuticals

Chemicals and Paints

Building Materials

Automotive Components

These machines protect goods during storage, shipping, and export packaging.

Safety Standards and Operator Protection

Emergency stop buttons

CE-compliant electrical components

Overload and motor protection systems

Controlled access during operation

These features protect operators and ensure regulatory compliance.

Frequently Asked Questions (FAQs)

Q1. What are pallet wrap precision settings?

They are controlled machine parameters that regulate film tension, stretch, and wrapping patterns for secure pallet containment.

Q2. How do precision settings reduce film waste?

They apply optimal stretch and tension, eliminating over-wrapping and unnecessary film usage.

Q3. Are precision settings suitable for fragile products?

Yes. Operators can adjust tension levels to safely wrap delicate and lightweight goods.

Q4. Can these machines integrate with automated lines?

Yes. Fully automatic models integrate seamlessly with conveyors, sensors, and ERP systems.

Q5. Do precision settings improve pallet wrap machine uptime?

Yes. Controlled operation reduces mechanical stress, breakdowns, and unplanned downtime.