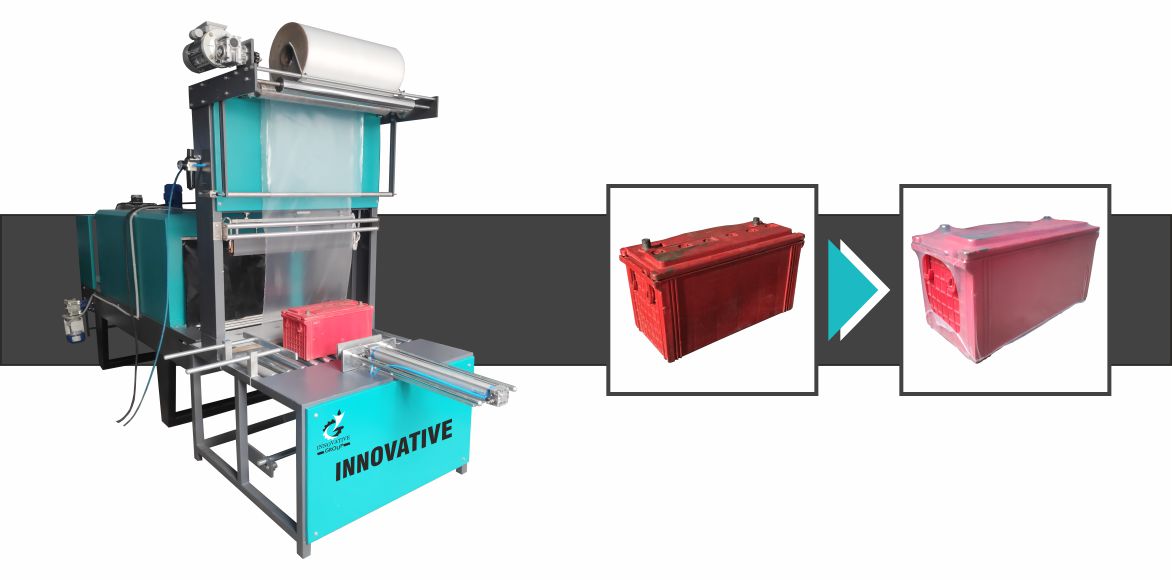

We are presenting fine quality Semi Automatic Battery Shrink Wrapping Machines with Manual Collation and with partial ‘U’ sealer. These products are developed from the best available technology.

Range:

Products such as a battery, bottles, tins, cans, boxes, containers, which are available in numerous configurations of 6, 12, 18 or 24 with/without a base tray or with the help of FLAT SHEET at the bottom, could be shrunk wrapped at various speeds of 5-15 packs per minute

stretch wrapping Similarly stretch packing After that product good looking In addition, I’m recording some video for stretch wrapping machine

Automatic Battery Packing Machine

An Automatic Battery Packing Machine is a high-precision industrial system designed to collate, count, align, wrap, seal, and pack batteries into retail-ready or bulk packaging formats without manual handling. The machine handles cylindrical batteries such as AA, AAA, C, D, as well as industrial battery cells, with consistent accuracy and output stability.

Innovative WrapTech Pvt. Ltd. engineers these machines to meet high-speed production demands, strict product safety requirements, and long-term operational reliability in battery manufacturing and packaging facilities.

Why Is This Machine Critical in Modern Industrial Operations?

Battery production requires precision, safety, and speed. Manual packing introduces inconsistencies, safety risks, and productivity limitations.

Industrial Importance:

Maintains consistent pack counts and orientation

Reduces manual handling of charged cells

Supports high-volume, continuous production

Improves packaging quality and shelf presentation

Ensures compliance with safety and transport standards

For battery manufacturers, automation directly protects both product quality and workforce safety.

What Types of Automatic Battery Packing Machines Are Available?

Automatic Shrink Packing Machine

Used for retail multipacks with clear visibility and compact packaging.

Advantages:

Low material cost

High-speed output

Clean visual presentation

Automatic Blister Packing Machine

Ideal for consumer-grade batteries requiring theft resistance.

Advantages:

Strong retail appeal

Long shelf life protection

Automatic Carton Packing Machine

Used for bulk and industrial battery packaging.

Advantages:

Strong transport protection

Easy palletization

High stacking stability

End-of-Line Integrated Packing Systems

Designed for fully automated battery production lines.

Advantages:

Minimal human intervention

Maximum throughput

Industry 4.0 compatibility

Innovative WrapTech Pvt. Ltd. configures each variant based on battery type, output speed, and packaging format.

What Best Practices Ensure Efficient Installation and Operation?

Installation Best Practices

Install on vibration-free, level flooring

Ensure proper electrical grounding

Maintain controlled temperature and humidity

Allow sufficient space for maintenance access

Operational Best Practices

Use approved packaging materials only

Monitor sensor calibration regularly

Maintain correct sealing temperatures

Train operators on fault diagnostics

What Maintenance Routines Keep Performance Consistent?

Daily Maintenance

Inspect belts, sensors, and guides

Check emergency stop functionality

Weekly Maintenance

Lubricate moving components

Inspect sealing elements and heaters

Verify PLC error logs

Long-Term Maintenance

Replace wear parts as per usage hours

Conduct electrical and safety audits

Upgrade firmware when required

Proactive maintenance prevents downtime and extends machine life.

What Safety Standards and Compliance Requirements Apply?

Battery packing systems must meet strict industrial safety norms.

Key Safety Measures:

Emergency stop circuits

Overcurrent and thermal protection

Fire-resistant electrical components

Compliance Standards:

ISO safety guidelines

CE conformity (export models)

Electrical safety and grounding standards

Innovative WrapTech designs machines with operator protection as a core engineering priority.

What Are the Future Trends in Battery Packing Automation?

Smart sensors and predictive maintenance

Vision-based quality inspection

Integration with MES and ERP systems

Energy-efficient servo technologies

Fully unmanned packaging lines

Innovative WrapTech Pvt. Ltd. builds machines ready for smart factory integration and Industry 4.0 environments.

Frequently Asked Questions (FAQs)

1. What types of batteries can this machine pack?

The machine can pack various batteries including lead-acid, lithium-ion, and nickel-metal hydride (NiMH) batteries, ensuring secure, dust-proof, and moisture-proof packaging.

2. Can it handle different battery sizes?

Yes. Adjustable guides, conveyor settings, and shrink tunnels allow the machine to accommodate multiple battery sizes and formats efficiently.

3. Which shrink films are compatible?

The machine supports PVC, PE (Polyethylene), and POF (Polyolefin) shrink films. POF film is preferred for its strength, clarity, and tamper-evident sealing.

4. What is the production capacity?

Depending on the model, the machine can pack 200–800 batteries per hour, making it suitable for small, medium, and high-volume production lines.

5. Is the machine easy to operate and maintain?

Yes. Minimal training is required. Routine maintenance includes cleaning, inspecting sealing blades, and checking heating elements to ensure consistent performance.