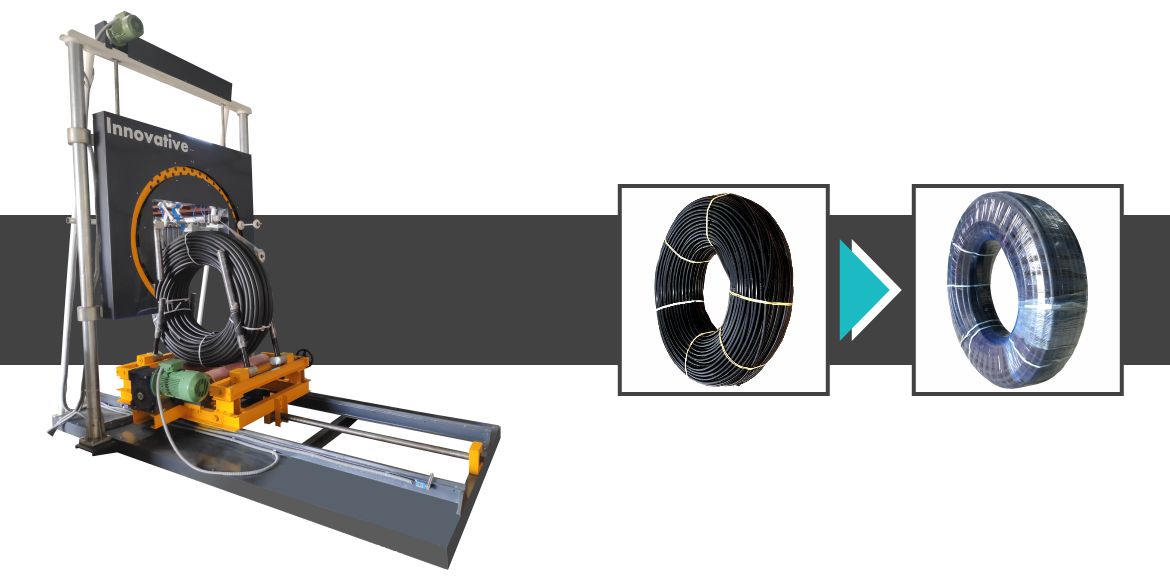

The Big HDPE Pipe Stretch Wrapping Machine is used for Spiral / Periphary Stretch Wrapping of Coil Shaped Products and Products with Long Dia.

Pipe COIL Film Wrpapping machine use To wrapping 50 Kg wire TO 1000 kG Hdpe Pipe wrap. ID: 1000 MM To 2500 MM, OD: 1200 MM To 3000 MM , width : 200MM To 500 MM.

The machine offers various controls for wrapping the stretch film and jute / paper roll at desired wrap tension and for wrapping different wrap configurations. The machine is designed for continuous operation and is rigid & sturdy. The machine is designed with an emphasis of functionality, reliability and ease of operation.

Coil wrapper wraps the coil shaped products in a spiral manner through eye of the product. This is a means of applying stretch film to a load consisting of stretch rollers supported on a vertical ring. It has a means of passing a load through ring’s eye horizontally.

Big HDPE Pipe Stretch Wrapping Machine

The hdpe pipe wrapping Machine is a ring stretch wrapper special designed for eye through packing which is an efficient equipment for coils packaging. There are different version pipe stretch wrapper per different coil size, handling way, packing material and handling requirement.

In market different types hdpe pipe coil packaging solution is available for a nice and uniform packaging for many products in coil side, such as hose coil, pipe coil, wire coil, bearing, cable…

How to working Big pipe packing machine:-

For big wire packing machine, the speed of ring and rollers are adjustable so that it is able wrap the coils by 360 degree. It is the most efficiency packing machine for coil objects and it was approved by thousand’s end user who asking for higher packaging rates and minimal space and lower labor costs.

By eye through packing: steel pipe packaging machine is able covering the packing material over all surfaces of coils by well controlled overlap . By different material, the packaging layer is able eliminates most of the air, dust, moisture from outsize.

choose the proper packing material on suction pipe stretch packing machine:-

the package is able reducing the corrosion, water spots, dust and rust. It protecting the surface of coil in storage and transportation on hdpe pipe coil.

Browse your entire range of big drip coil packaging requirement in size, speed and packing material and selecting the right solution that are suitable for you.

There are also various features available in hdpe pipe stretch Wrapping Machine:-

1.) Adjustable Film Overlap

2.)PLC based Operations

3.) Automatic cutting and holding of film in machine.

4.)Adjustable stretch ratio.

5.) Vibration free Operation

6.) brand PLC base operation for temporal arrangement of wrapping

7.) Rotation, Cutting, ejection available.

8.) Advance paper relish system

How to use hdpe pipe stretch film Wrapping Machine:-

1.) First of all put product in machine.

2.) Then press START use button.

3.)Automatic wrapping & tapping will be start just after starting machine.

4.)The machine will be stop on which count you had set.

5.)Lastly Start ejector after starting that product will come outside.

Advantages of HDPE Pipe Packing Machine

Protects from Dust, Moisture, and Foreign Particles

The machine prevents dust, moisture, and other foreign particles from entering the coil during storage and transport.Prevents Tampering

It secures the product, ensuring safety from tampering or unauthorized handling.Ensures Uniform and Consistent Packing

The machine wraps every coil consistently, maintaining uniformity and professional presentation.Saves Packaging Labor, Cost, and Time

Automation reduces manual labor, lowers packaging costs, and speeds up the wrapping process.

Frequently Asked Questions

1. How much does it cost to wrap an HDPE pipe?

It is difficult to give an exact answer because HDPE pipe coils vary in size. For estimation, consider a small coil, like a binding wire coil available in the market: Inner diameter 200mm, Outer diameter 450mm, Width 100mm, Weight 25kg. Wrapping this coil with stretch material requires approximately 50g of film. Converting this into currency, the wrapping cost comes to around 4–5 rupees per coil.

2. What is the price of an HDPE pipe stretch wrapping machine?

Pricing depends on coil size and customization. For small coils, machines start at ₹12.5 lakh, while for larger coils, prices go up to ₹35 lakh.

3. How many coils can a flexible pipe wrapping machine wrap?

The production rate depends on coil size. A small coil wrapping machine can wrap 40–45 coils per hour, while a machine for larger coils wraps 25–30 coils per hour.

4. What are the dimensions of the largest coil an HDPE pipe wrapping machine can wrap?

We customize drip pipe wrapping machines according to client requirements. The maximum coil size we can wrap is: Inner diameter 2.5m, Outer diameter 3m, Width 0.5m, Weight 10 tons.

5. Which type of film can a coil wrapping machine use?

The film depends on the industry and product:

Wire Industry: HDPE film, Rafia material, or stretch film.

Flexible Pipe Industry: Mainly stretch film; some clients prefer mulching film.

Tyre Industry: Metallized polyester film and LDPE film.