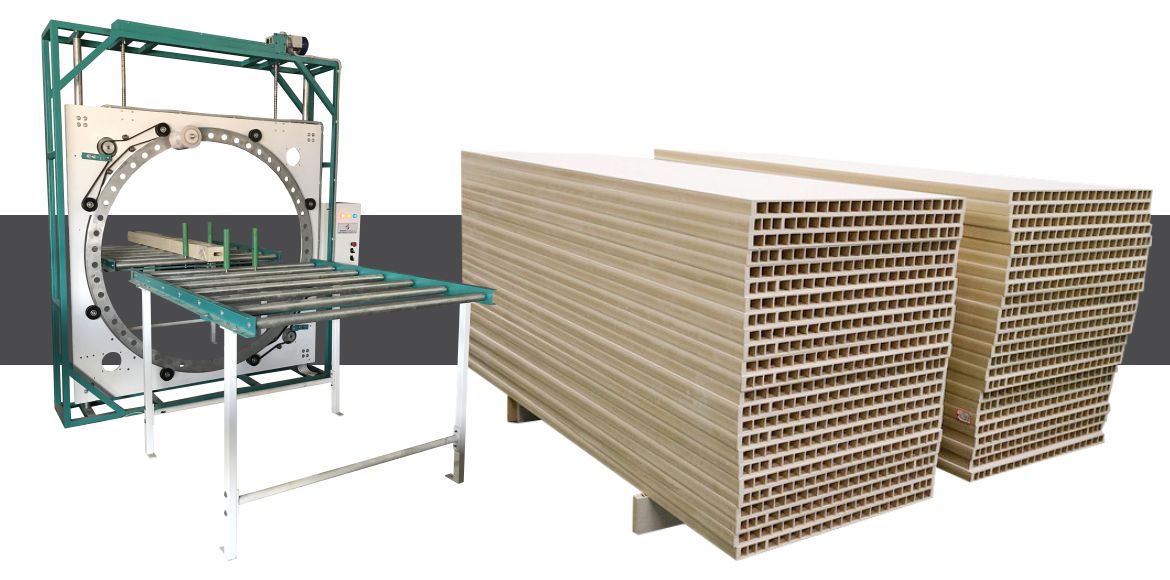

Big Product Orbital Packing Machine are ideal for long loads that can not be stretch wrapped on a conventional turntable or rotary tower type machine.

Examples of products that are well suited for orbital wrapping pipe, plastic extrusions, carpet rolls, lumber, aluminum siding, and many other long products.

Ring sizes from 15 inch to 90 inch are available to accommodate virtually all orbital wrapping applications.

Big Product Orbital Packing Machine

big product orbital stretch wrapping machine use to packing for Big size in Width and height like doors, FRP profiles and steel pipes many more..

we make customize orbital stretch packing machine in India

and also exports in all over worlds

How to work Big orbital stretch wrapping machine:-

Almost everything is done automatically on the fully automatic ring packing machine. All you have to do is load a product onto the conveyor and then the product will move forward automatically. When the product arrives at the packing station, it doesn’t even have to be wrapped in foil, it should be done automatically.

And when the final product arrives after wrapping the film, the wrapping machine will automatically know that the final product has arrived with the help of the product sensor, and then the automatic wrapping machine will even cut the film automatically, and the product will go on the output tape. So basically we mean that you only have to do the loading and unloading of the product. Everything else is done automatically. When your product hits a conveyor,

this orbital stretch wrapper machine will come in handy.In this situation, you don’t need to upload and download as well. We make custom packaging machine so we can make the machine according to the height, weight and width of your product.

Advantages of orbital stretch film packing machine:-

Protection against scratches during transport.

The packaging process can be automated.

Form of packaging accepted worldwide

Protection against dust, humidity and foreign particles.