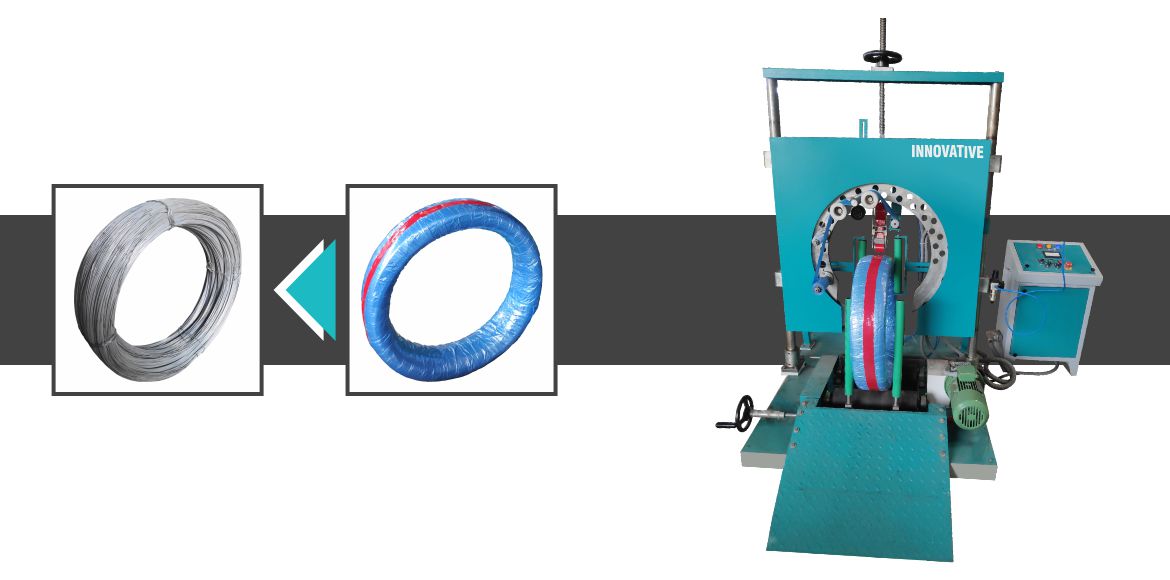

The coil Wrapping machine is applied in various type of products including PVC Wires & Cables, Stitching wire Coil, Braided Pipe Coil, Vehicle Tyres,

Pneumatic Pipe Bundles, Welding Wire Coils, paper reels, Sheet Metal Coils, Laminate Rolls for packing purpose.

Steel Wrapping Machine, Steel Bars Wrapping Machine, are used in Steel Industries. In PVC Wires & Cables Binding Wire Wrapping Machine,

In Braided Pipe Coil HDPE Automatic Pipe Coiling Machine, Wrapping Machine For HDPE pipe coil, and Irrigation Industry Tyre Drip Pipe Steel Wrapping Machines are used for their packaging convenience.

The Stretch wrapping machine is also mainly used in Wire& Cables Industry by wire Ring Machine, Wire Rolling Machine, Gemini Tyre Retreading Machine, Automatic Wire ring machine,

Copper Wire Ceiling Machine, Wire Coiler Machine, further PSC Pole Wire Stretching Machine, Single Geared Wire Rolling machine, Italian Model Wire Rolling Machine, MS Wire Wrapping machine,

Iron Wire Ring machine, Manual MS Casting Wire Mesh Packing machine, are used in huge amount.

Coil Wrapping Machine Manufacturer

A Coil Wrapping Machine is an industrial-grade packaging solution designed to secure metal, paper, textile, or other cylindrical coils with protective stretch or shrink film. It ensures load stability, surface protection, and safe transportation, reducing manual labor and packaging costs.

Innovative WrapTech Pvt. Ltd. manufactures high-performance coil wrapping machines for factories, warehouses, and export-oriented industries, offering reliable, uniform, and cost-effective packaging.

How the Coil Wrapping Machine Works

Coil Placement

The operator positions the coil on the rotating turntable, cradle, or loading platform.Film Attachment

The stretch or shrink film is manually attached to the coil base.Cycle Initiation

The operator starts the wrapping cycle via a push-button or PLC control.Rotation & Wrapping

The turntable rotates the coil while the film carriage moves vertically to wrap the coil evenly.Tension Control

The machine applies consistent film tension to secure the load without deformation.Cycle Completion

The film cuts or releases automatically; the machine stops after completing the programmed wraps.Coil Removal

The wrapped coil is ready for storage, transport, or export.

This automated process ensures consistent wrapping quality and reduces labor dependency.

Why Coil Wrapping Machine Manufacturer Are Critical in Industrial Operations

Modern industrial operations demand efficiency, safety, and cost-effectiveness. A coil wrapping machine:

Prevents coil surface damage and corrosion

Reduces manual labor and operator fatigue

Minimizes film waste and packaging costs

Increases load stability during transport

Delivers uniform, professional-grade wrapping

Supports high-volume production without compromising quality

Key Technical Features and Operational Benefits

| Feature | Benefit |

|---|---|

| Variable turntable speed | Prevents coil shifting and damage |

| Adjustable film tension | Ensures uniform wrapping, saves film |

| PLC control or push-button interface | Reliable, repeatable operation |

| Emergency stop and safety guards | Protects operators during operation |

| Heavy-duty industrial frame | Supports continuous operation |

| Photo-eye height sensor | Detects coil height accurately for precise wrapping |

Installation, Operation, and Maintenance Best Practices

Installation:

Install on flat, reinforced flooring

Ensure electrical grounding and power compliance

Maintain adequate clearance around the machine

Daily Operation:

Check film carriage and rollers for smooth movement

Use recommended film type and thickness

Weekly Maintenance:

Inspect belts, tension systems, and mechanical components

Clean turntable, sensors, and film guides

Long-Term Maintenance:

Calibrate speed and tension settings quarterly

Replace worn mechanical or electrical parts

Perform full inspection every 6–12 months

Why Manufacturers Prefer Professional-Grade Machines

Low-cost alternatives often fail under continuous industrial operation, causing:

Increased downtime and maintenance costs

Safety risks for operators

Professional-grade machines from Innovative WrapTech Pvt. Ltd. ensure durable, reliable, and high-performance operation.

A Coil Wrapping Machine from Innovative WrapTech Pvt. Ltd. offers

Safe, consistent, and high-quality coil packaging

Easy operation and minimal operator training

Cost savings in labor, material, and transport damage

Scalable automation for future factory integration

For high-volume industrial coil operations, this machine provides efficiency, safety, and long-term reliability.

Frequently Asked Questions (FAQs)

1. What is a Coil Wrapping Machine?

A Coil Wrapping Machine is an industrial machine designed to securely wrap cylindrical coils with stretch or shrink film. It protects coils during storage, handling, and transport while reducing manual labor and packaging waste.

2. How does a Coil Wrapping Machine work?

The operator places the coil on the turntable or cradle, attaches the film, and starts the cycle. The machine rotates the coil while the film carriage moves vertically, wrapping the coil evenly with controlled tension. The cycle finishes automatically, leaving a fully wrapped coil.

3. Which industries use Coil Wrapping Machines?

Industries using these machines include steel, aluminum, copper, paper, textile, chemicals, plastics, and logistics. Any operation handling heavy or large-diameter coils benefits from consistent coil wrapping.

4. What types of coils can it wrap?

It can handle steel, aluminum, copper, paper, textile, and plastic coils of various diameters, widths, and weights, including both uniform and irregular shapes.

5. Is a Coil Wrapping Machine suitable for small businesses?

Yes. Semi-automatic models offer affordable, easy-to-use solutions for small to medium-scale operations that need reliable coil packaging without high automation costs.