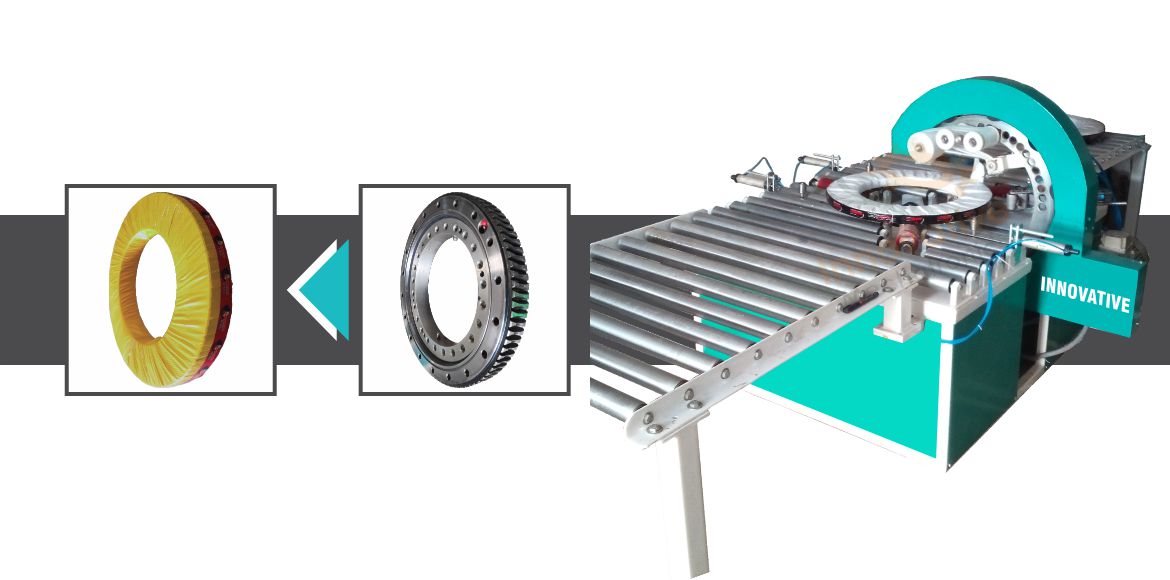

The Fully Automatic Horizontal Coil Wrapping Machine With- Conveyor System also called Wire & Cable Film Wrapping Machine is used for Spiral / Periphery Stretch Wrapping of Coil Shaped Products and Products with Long Lengths.

Fully Automatic Horizontal Coil Wrapping Machine With- Conveyor System use To wrapping 2 Kg To 50 Kg wire bandal Film Wrapping. ID : 150 To 500 MM, OD: 200 To 700 MM and Width : 20 To 100 MM.

The machine offers various controls for wrapping the stretch film and jute/paper roll at desired wrap tension and for wrapping different wrap configurations. The machine is designed for continuous operation and is rigid & sturdy. The machine is designed with an emphasis of functionality, reliability, and ease of operation.

Coil wrapper wraps the coil-shaped products in a spiral manner through the eye of the product. This is a means of applying the stretch film to a load consisting of stretch rollers supported on a vertical ring. It has a means of passing a load through ring’s eye horizontally.

Fully Automatic Horizontal Coil Wrapping Machine with Conveyor System

A Fully Automatic Coil Wrapper is an industrial packaging machine that wraps coils using stretch film, HDPE, LDPE, or specialty films without manual handling. The machine automatically receives coils from a conveyor, positions them, wraps them uniformly through a rotating ring or orbital system, and discharges them back to the conveyor.

Manufacturers use this machine to protect coils from dust, moisture, corrosion, and mechanical damage during storage and transportation.

How Does a Fully Automatic Coil Wrapper Work? (Step by Step)

The conveyor feeds the coil into the wrapping station.

Sensors detect the coil size and confirm its position.

The machine centers and clamps the coil automatically.

The rotating ring or orbital arm applies the wrapping film around the coil circumference.

The film overlaps uniformly to ensure full surface coverage.

The machine cuts and clamps the film automatically after wrapping.

The conveyor discharges the wrapped coil for stacking or dispatch.

This fully automated process eliminates manual lifting and reduces packaging time.

Why Is This Machine Important in Modern Industrial Operations?

The Fully Automatic Coil Wrapper improves productivity and consistency in high-volume manufacturing environments. It reduces labor dependency, minimizes packaging material waste, and ensures uniform protection for every coil.

Manufacturers rely on this machine to:

Increase packaging speed

Improve workplace safety

Maintain consistent packaging quality

Types and Variants of Fully Automatic Coil Wrappers

1. Horizontal Coil Wrapper with Conveyor

Use this model when production lines run continuously and coils move automatically between processes.

2. Tapping System Coil Wrapper

Use this model when branding or labeling on the coil’s outer surface is required.

3. Semi-Automatic Coil Wrapper

Use this variant for lower production volumes or manual loading requirements.

4. Heavy-Duty Coil Wrapper

Use this version for large, wide, or heavy steel and aluminum coils.

Key Technical Features and Operational Benefits

| Feature | Operational Benefit |

|---|---|

| Automatic conveyor integration | Eliminates manual handling |

| PLC and HMI control system | Enables precise control and easy operation |

| Adjustable wrapping tension | Prevents coil deformation |

| Sensor-based size detection | Ensures accurate wrapping |

| Automatic film cutting | Saves time and material |

| Variable speed drive | Matches production line speed |

Standard Industry-Level Technical Specifications

Inner diameter: 200 mm to 2.5 m

Outer diameter: 300 mm to 3 m

Coil width: 50 mm to 500 mm

Maximum weight: Up to 10 tons

Wrapping material: Stretch film, HDPE, LDPE, raffia, polyester

Power supply: 380–415V, 3-phase

Control system: PLC with HMI

Wrapping speed: 20–45 coils per hour (model dependent)

Conclusion

A Fully Automatic Coil Wrapper is a critical investment for manufacturers seeking speed, safety, and consistent packaging quality. By selecting the right model and maintaining proper operating practices, industries can achieve higher productivity, reduced losses, and long-term operational reliability.

Frequently Asked Questions (FAQs)

Q1. What is a Fully Automatic Horizontal Coil Wrapping Machine with Conveyor System?

A Fully Automatic Horizontal Coil Wrapping Machine with Conveyor System is designed to automatically wrap coils while using conveyors for smooth infeed and outfeed during high-volume operations.

Q2. What types of coils can this machine wrap?

The machine can wrap steel coils, aluminum coils, copper coils, wire coils, and other circular or ring-shaped products, depending on the model.

Q3. How does the conveyor system improve productivity?

The conveyor system automates coil loading and unloading, reduces manual handling, and enables continuous wrapping for higher production efficiency.

Q4. Is this machine suitable for heavy-duty industrial use?

Yes. The machine is built for heavy-duty industrial environments and can handle large, heavy coils with consistent wrapping performance.

Q5. Which industries commonly use this machine?

Industries such as steel processing, metal fabrication, wire manufacturing, automotive, and logistics commonly use this machine.