Automatic L-seal cutting machine is a fully automatic unmanned L sealing cutter, widely used for lot production pipelining with high efficiency. The machine is equipped with an auto film feeding & perforating device and adjustable product infeed conveying table in order to meet different requirements from different products.

Fully automatic L-sealers are high-speed L-sealing solutions for wrapping using polyolefin film. The automatic L-sealers can be used in combination with shrink tunnels.

automatic L-sealers are ideal for high speed, providing excellent performance and value for money.

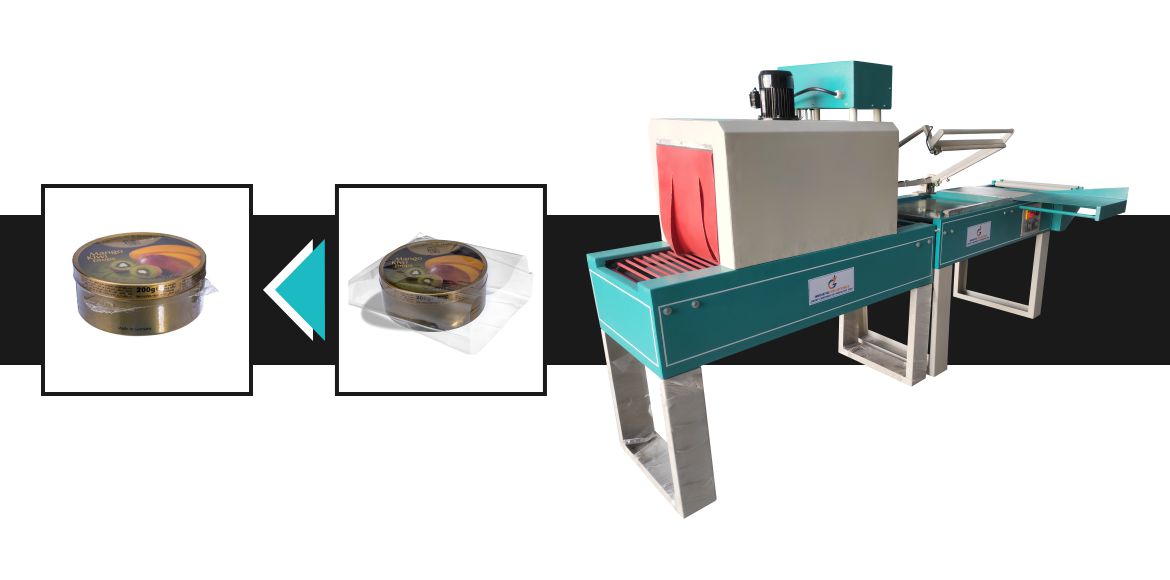

The complete system consists of a fully automatic L-sealing machine and a separate heat shrink tunnel.

The speed of the system is up to 25 packs per minute. The machine is fully automatic and an operator is only required for loading packets, monitoring, and film changing.

L-Sealer Machine For Wire and cable

Description:-

An automatic L-seal cutting machine is a fully automatic unmanned L sealing cutter, widely used for lot production pipe lining with high efficiency. The machine is equipped with an auto film feeding & perforating device and adjustable product in feed conveying table in order to meet different requirements from different products.

Fully automatic L-sealers are high-speed L-sealing solutions for wrapping using polyclinic film. The automatic L-sealers can be used in combination with shrink tunnels.

automatic L-sealers are ideal for high speed, providing excellent performance and value for money.

Therefore, The complete system consists of a fully automatic L-sealing machine and a separate heat shrink tunnel.

The speed of the system is up to 25 packs per minute. The machine is fully automatic and an operator is only required for loading packets, monitoring, and film changing.

Operation:-

automatic L-sealers use center folded polyclinic(POF) film. In this machine, a conveyor feeds the product into the film. The machine measures the length of the product using a sensor and the sealing jaws operate automatically to perform sealing.

After the bag is sealed, it is automatically conveyed into a heat shrink tunnel where film shrinking takes place and the skin-tight wrap is produced. The film which is trimmed off during the packaging process is automatically wound up on a waste film take-up reel.

After that, Fully automatic L-sealers have a microprocessor-based user interface and have a PLC based back-end. machines have added features of preset programs, error display, total count, day count, count of damaged packs, etc.

Features:-

Firstly, Fully automatic

Secondly, L-sealing

Thirdly, a Microprocessor-based interface

PLC back-end

Preset programs

Digital display

Pre- Settable product counters

Error display

Waste film take-up

Friction conveyor

What are the advantages of using the Automatic L Sealer machine?

Firstly, Available in two different sizes

Secondly, Very fast shrink wrapping machine – can wrap 30 items per minute

Thirdly, Very little operating needed

Can process heavy-duty wrapping

Can be rented on long and short term loans

Application:-

The L-sealer machine is suitable for shrink packing electronic products, hardware, software, foodstuff, printing, pharmacy, floor, ceramics, etc in small amounts.

Applied to all kinds of packing materials, such as PVC, POF, PP.

Video:-

Clients from all over the world are opting for the products manufactured by our company because we ensure