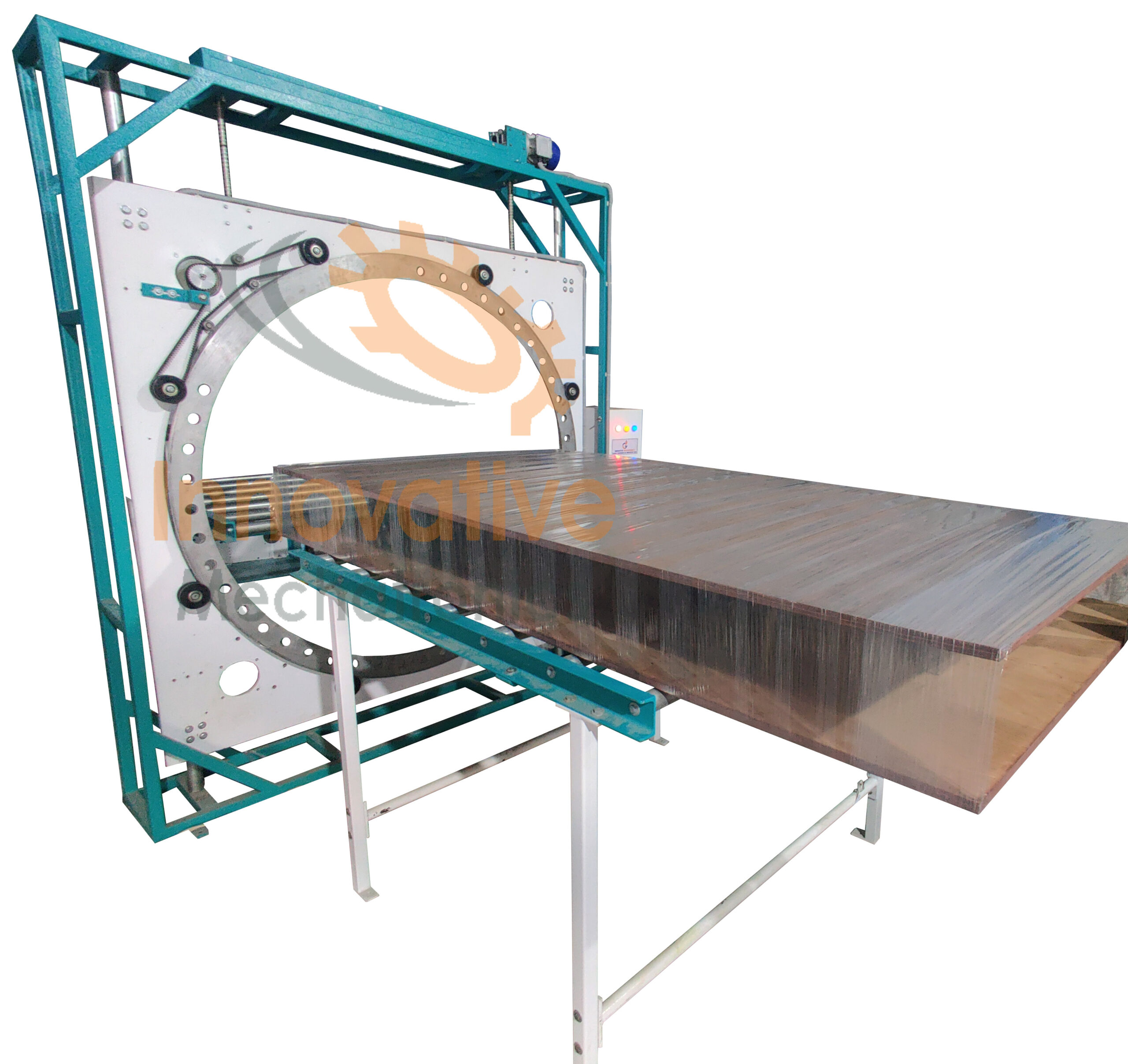

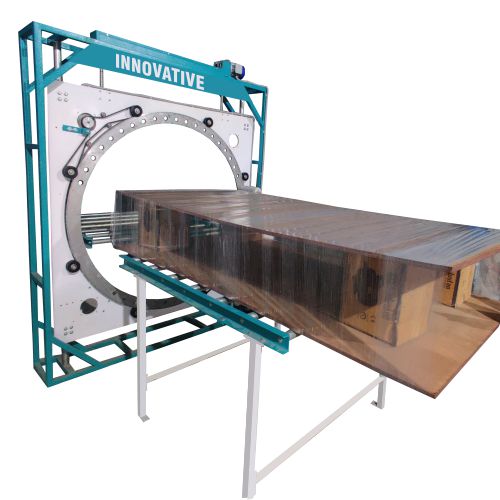

Door Frame Packing Machine

A Door Frame Packing Machine is an industrial packaging solution designed to wrap solid door frames, wooden frames, metal frames, and edge band materials using stretch film, protective film, paper, or foam-laminated materials. The machine applies uniform tension and controlled overlap to protect edges, corners, and surfaces during handling, storage, and transportation.

Manufacturers use this machine to achieve consistent, damage-free, and professional packaging at scale.

Why Is This Machine Important in Modern Industrial Operations?

Door frames are long, rigid, and edge-sensitive products. Manual packing often causes scratches, dents, and inconsistent protection. This machine:

Prevents surface and edge damage

Improves packaging speed and consistency

Reduces labor dependency and fatigue

Minimizes material wastage

Enhances logistics and transport safety

Supports export-grade packaging standards

Modern manufacturers rely on automation to maintain quality, efficiency, and brand reputation.

Types & Variants of Door Frame Packing Machines

Manual Door Frame Packing System

Best for very low volumes

High labor involvement

Limited consistency

Semi-Automatic Door Frame Packing Machine

Manual loading with automated wrapping

Ideal for small to medium factories

Cost-effective and reliable

Fully Automatic Door Frame Packing Machine

Conveyor-integrated system

Designed for high-volume production

Maximum speed and minimal manpower

Horizontal Packing Machine

Provides stable, uniform wrapping

How Buyers Can Choose the Right Model

Capacity

Select based on daily production output and frame size.

Material Type

Choose compatible film systems for wood, metal, or laminated surfaces.

Automation Level

Manual: Very small workshops

Semi-automatic: Growing factories

Fully automatic: Large-scale plants

Budget

Balance upfront cost with long-term labor and material savings.

Floor Space

Horizontal machines suit long layouts; compact designs suit smaller floors.

Best Practices for Installation, Operation & Maintenance

Installation

Ensure proper electrical grounding

Align infeed and outfeed rollers

Operation

Set correct film tension and overlap

Use suitable film thickness

Train operators on control systems

Maintenance

Clean rollers and sensors daily

Lubricate moving parts weekly

Inspect motors, belts, and cutters regularly

Schedule preventive maintenance every 6–12 months

Conclusion

A Door Frame Packing Machine delivers consistent protection, faster throughput, and lower operational risk. It is an essential investment for manufacturers seeking quality, efficiency, and scalability in modern production environments.

FAQs

1. What is a Door Frame Packing Machine?

A Door Frame Packing Machine is an industrial packaging system that wraps solid wooden, metal, or composite door frames and edge bands with protective film to prevent damage during handling, storage, and transportation.

2. Which materials can this machine pack?

The machine packs solid wood frames, engineered wood frames, metal door frames, PVC frames, laminated frames, and edge band materials.

3. How does a door frame packing machine work?

The machine feeds the frame through rollers while an orbital wrapping ring applies film with controlled tension and overlap, ensuring full surface and edge protection.

4. Why is automated door frame packing better than manual packing?

Automated packing provides uniform wrapping, reduces labor effort, improves speed, minimizes material waste, and protects delicate edges more effectively than manual methods.

5. What types of packing films does the machine support?

The machine supports stretch film, LDPE film, foam-laminated film, protective paper, and surface-protection films based on application needs.