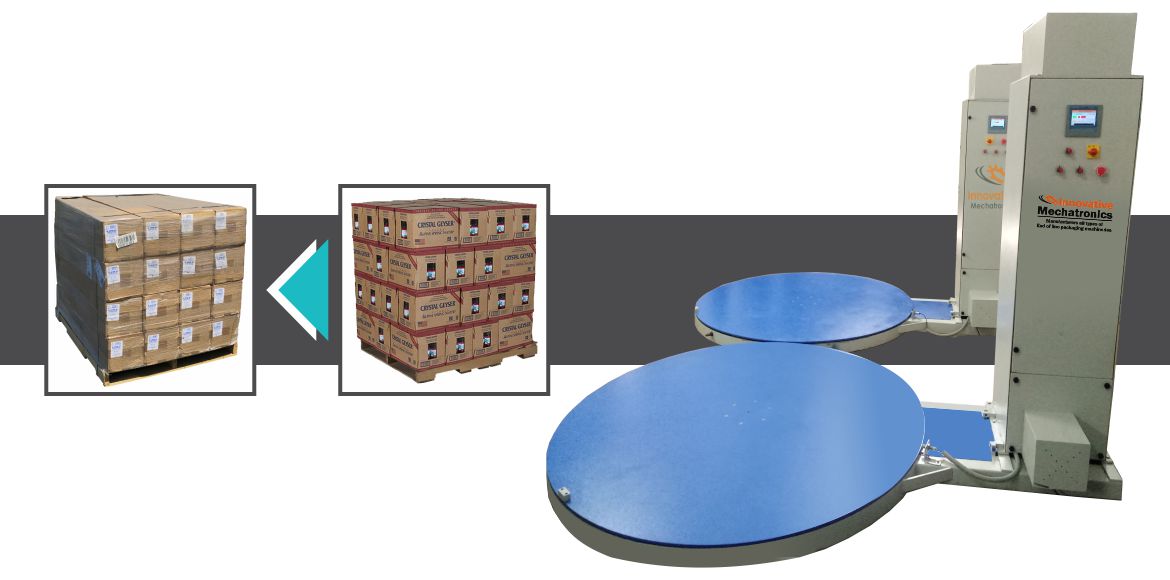

Pallet Stretch wrapping machines are used to wrap stretch film around a loaded pallet. The film provides extra support while the products are being transported & stored to protect them from tip, spill, or from being damage.

Additionally, wrapped loads can easily be separated and identified. Stretch pallet wrapper is widely used in the chemical industry, electronic industry, pharmaceutical industry, building materials home appliances papermaking foodstuff & drink, etc.

Pallet Wrapping Machine Manufacturer

A pallet wrapping machine is an industrial packaging system designed to securely wrap goods stacked on pallets using stretch film. The machine stabilizes loads, protects products from dust, moisture, and transit damage, and ensures uniform packaging consistency across operations.

Innovative WrapTech Pvt. Ltd. manufactures advanced pallet wrapping machines engineered for high efficiency, durability, and compliance with global industrial standards.

How a Pallet Wrapping Machine Works

Pallet Placement

The operator places the loaded pallet on the turntable or conveyor system.Film Attachment

The stretch film is automatically or manually attached to the pallet base.Rotation & Film Stretching

The pallet rotates while the film carriage moves vertically, applying controlled tension for uniform wrapping.Layer-by-Layer Wrapping

The machine wraps the pallet from bottom to top, ensuring load stability and edge protection.Film Cutting & Sealing

The system cuts and seals the film automatically or semi-automatically.Load Discharge

The wrapped pallet exits safely, ready for storage or transportation.

This automated cycle ensures consistent results regardless of operator skill level.

Key Technical Features & Operational Benefits of Pallet Wrapping Machine Manufacturer

| Feature | Operational Benefit |

|---|---|

| Pre-stretch film carriage | Saves up to 30% film cost |

| PLC-based control panel | Easy operation and repeatability |

| Adjustable wrapping programs | Handles diverse pallet sizes |

| Safety sensors & emergency stops | Ensures operator protection |

| Heavy-duty steel frame | Long service life |

Installation, Operation & Maintenance Best Practices of Pallet Wrapping Machine Manufacturer

Installation

Level foundation

Stable power supply

Proper machine anchoring

Operation

Follow programmed wrapping cycles

Train operators on safety protocols

Maintenance

Weekly inspection of rollers and belts

Lubricate moving parts

Periodic PLC diagnostics

Preventive maintenance ensures long service life and maximum uptime.

Why Manufacturers Prefer Professional-Grade Machines from Innovative WrapTech

Proven industrial reliability

Custom-engineered solutions

Strong after-sales support

Long-term ROI and durability

Professional manufacturers invest in machines that scale with growth—and Innovative WrapTech delivers exactly that.

Frequently Asked Questions (FAQs)

Q1. How much power does a pallet wrapping machine consume?

Most machines operate efficiently on standard industrial power with low energy consumption.

Q2. Can the machine handle different pallet sizes?

Yes, adjustable programs allow wrapping of varied pallet dimensions.

Q3. Is operator training required?

Minimal training is sufficient due to user-friendly PLC controls.

Q4. What is the average machine lifespan?

With proper maintenance, machines operate reliably for 10–15 years.

Q5. Can the machine integrate with conveyors or ERP systems?

Yes, fully automatic models support conveyor and smart factory integration.

Conclusion

A pallet wrapping machine manufactured by Innovative WrapTech Pvt. Ltd. is a strategic investment for modern industries seeking efficiency, safety, and packaging consistency. With robust engineering, intelligent automation, and industry-focused design, these machines deliver measurable productivity gains and long-term value.