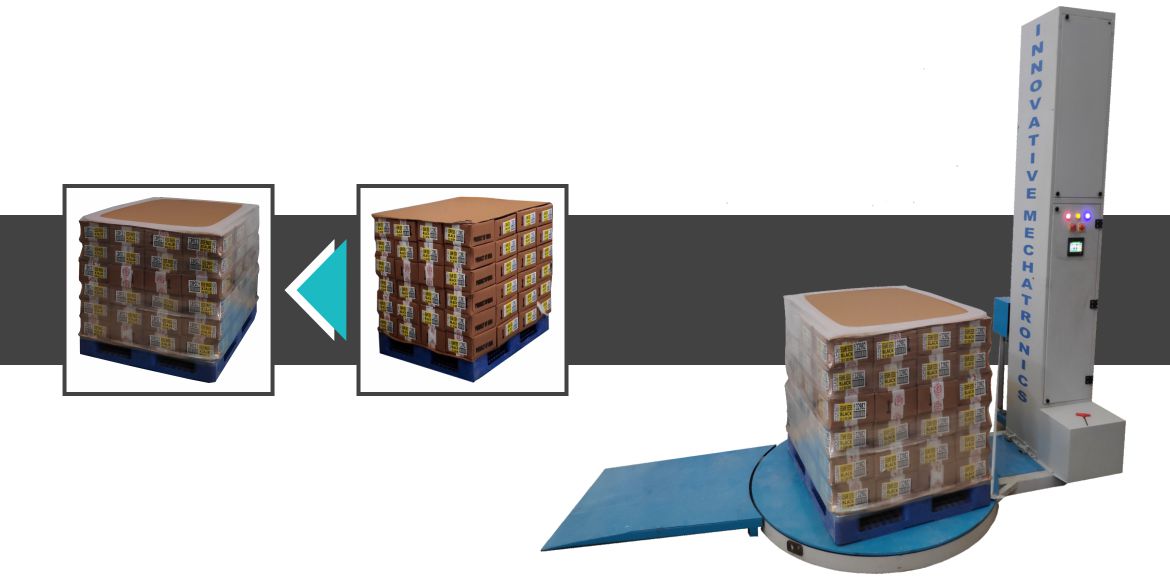

The concept of Pallet Wrapping Machine With Scale as the name suggests entails the scale with a pallet wrapper.

It is the ideal machine for wrapping stable loads of under 2000 kg. They are typically less expensive than rotary arm wrappers.

Pallet wrapping is the most common form of load containment around, used for securing product to pallets for distribution, storage, and protection from the elements.

It is applied in different industries like Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverages and etc…

There are different applications of pallet wrapping machines with a scale which are the following:- APPAREL, Beverage, Chemical, Commodity, Food, Machinery…

What Is a Pallet Wrapping Machine Scale?

A Pallet Wrapping Machine Scale is an advanced industrial packaging system that wraps palletized goods and weighs them simultaneously. The integrated weighing scale measures the exact pallet weight during the wrapping process, eliminating the need for separate weighing stations.

Innovative WrapTech Pvt. Ltd. designs these machines to improve packaging accuracy, logistics control, safety, and operational efficiency in high-volume industrial environments.

Why This Machine Is Important in Modern Industrial Operations

Modern supply chains demand speed, accuracy, traceability, and compliance. Manual weighing and wrapping slow operations and introduce errors.

A Pallet Wrapping Machine Scale:

Reduces handling time by combining weighing and wrapping

Ensures accurate shipping weights for billing and compliance

Prevents overloading in transport vehicles

Improves warehouse productivity and throughput

Enhances operator safety by minimizing manual lifting

Manufacturers rely on this machine to maintain consistent packaging quality while controlling logistics costs.

How to Choose the Right Pallet Wrapping Machine Scale

1. Based on Capacity

Light to medium pallets (500–1,500 kg): Standard turntable models

Heavy pallets (1,500–3,000+ kg): Rotary arm or reinforced turntable models

Choose a machine that exceeds your maximum pallet weight to ensure long-term reliability.

2. Based on Material Type

Fragile cartons require low tension control

Rigid industrial goods require high pre-stretch tension

Irregular loads benefit from programmable wrapping cycles

3. Based on Automation Level

Semi-automatic: Best for low to medium production volumes

Fully automatic: Ideal for high-volume lines with conveyors and palletizers

4. Based on Budget

Entry-level machines offer basic weighing and wrapping

Professional-grade systems deliver higher accuracy, durability, and automation

Long-term ROI often outweighs the initial cost

Reasons Manufacturers Prefer Professional-Grade Machines

Higher weighing accuracy

Consistent packaging quality

Reduced downtime and maintenance

Compliance with export and logistics standards

Better operator safety and ergonomics

Professional machines deliver reliability, precision, and scalability.

Frequently Asked Questions (FAQ)

1. What is the purpose of a pallet wrapping machine scale?

It wraps palletized goods and measures their weight in one operation, improving efficiency and accuracy.

2. How accurate is the integrated weighing system?

Industrial models typically provide accuracy within ±0.5% to ±1%, depending on configuration.

3. Can the machine handle heavy pallets?

Yes. Heavy-duty models support pallet weights exceeding 3,000 kg.

4. Does this machine eliminate the need for floor scales?

Yes. It removes separate weighing stations, saving space and time.

5. Is the machine suitable for automated production lines?

Yes. Fully automatic versions integrate seamlessly with conveyors and palletizers.