We are presenting fine quality Shrink Wrapping Machine For MiG Wire Spool with Manual Collation and with partial ‘U’ sealer. These products are developed from the best available technology.

Range:

- Products such as a battery, bottles, tins, cans, boxes, containers, which are available in numerous configurations of 6, 12, 18 or 24 with/without a base tray or with the help of FLAT SHEET at the bottom, could be shrunk wrapped at various speeds of 5-15 packs per minute

- stretch wrapping Similarly stretch packing After that product good looking In addition, I’m recording some video for stretch wrapping machine

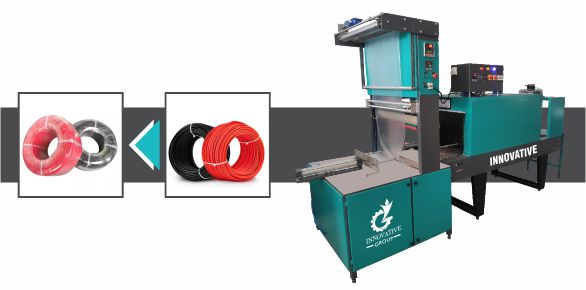

Shrink Wrapping Machine for MiG Wire Spool

The Shrink Wrapping Machine for MiG Wire Spool manufactured by Innovative WrapTech Pvt. Ltd. delivers strong, moisture-resistant, and uniform packaging for MiG welding wire spools. This machine improves product safety, shelf life, and handling efficiency in industrial packaging environments.

How the MiG Wire Spool Wrapper Improves Packaging Efficiency

The Shrink Wrapping Machine for MiG Wire Spool operates on standard industrial electrical power and supports continuous production with controlled energy usage.

Innovative WrapTech Pvt. Ltd. designs the system with insulated shrink tunnels, optimized heaters, and efficient air circulation to minimize heat loss and reduce electricity consumption. The machine works reliably in manufacturing plants without requiring special power infrastructure.

How Long Is the Expected Service Life of the Machine?

The Shrink Wrapping Machine for MiG Wire Spool is engineered for long-term industrial use and heavy-duty operation.

With proper maintenance and correct operating practices, the machine typically delivers a service life of 8 to 12 years or more. Its robust frame, industrial-grade electrical components, and heat-resistant materials ensure consistent performance even under continuous production conditions.

Different Types or Variants Available and When Each Is Used

Innovative WrapTech Pvt. Ltd. offers multiple variants of the Shrink Wrapping Machine for MiG Wire Spool to match different production capacities.

Semi-automatic models suit small and medium-scale units where manual loading is acceptable.

Fully automatic systems support high-volume production lines with minimal human intervention.

Tunnel-type configurations ensure uniform shrink quality for export-grade and premium packaging requirements.

Each variant improves packaging consistency while aligning with specific operational needs.

Key Technical Features MiG Wire Spool Wrapper with Real Operational Benefits

The Shrink Wrapping Machine for MiG Wire Spool includes industrial-grade features that deliver direct operational advantages.

Uniform heat circulation ensures wrinkle-free and tight wrapping

Adjustable temperature control supports different spool sizes and film types

Heavy-duty conveyor handles metal spools smoothly

Fast heating cycle increases packaging speed

Low-maintenance design reduces downtime and service costs

These features help manufacturers achieve reliable output and consistent packaging quality.

Standard Technical Specifications of MiG Wire Spool Wrapper

Power Supply: 220V / 380V AC, 50 Hz

Power Consumption: 6–18 kW (model dependent)

Shrink Tunnel Temperature: Adjustable up to 200°C

Supported Film Types: LDPE / PVC

Machine Structure: Powder-coated MS (SS optional)

Control System: Digital temperature controller with safety protections

These specifications meet standard industrial packaging requirements and allow customization based on application.

Frequently Asked Questions (FAQs)

1. What does this machine package?

This machine packages MiG welding wire spools by applying heat-shrink film that tightly seals and protects the product from dust, moisture, and corrosion during storage and transportation.

3. What power supply does the machine require?

The machine operates on standard industrial electrical power and supports both single-phase and three-phase connections, depending on the selected model and production capacity.

4. Can the machine handle different spool sizes?

Yes, the machine supports adjustable settings that allow operators to package various MiG wire spool diameters and widths without compromising shrink quality.

5. Is the machine suitable for continuous industrial operation?

Yes, Innovative WrapTech Pvt. Ltd. designs the machine for continuous operation using heavy-duty components, heat-resistant insulation, and stable temperature control systems.